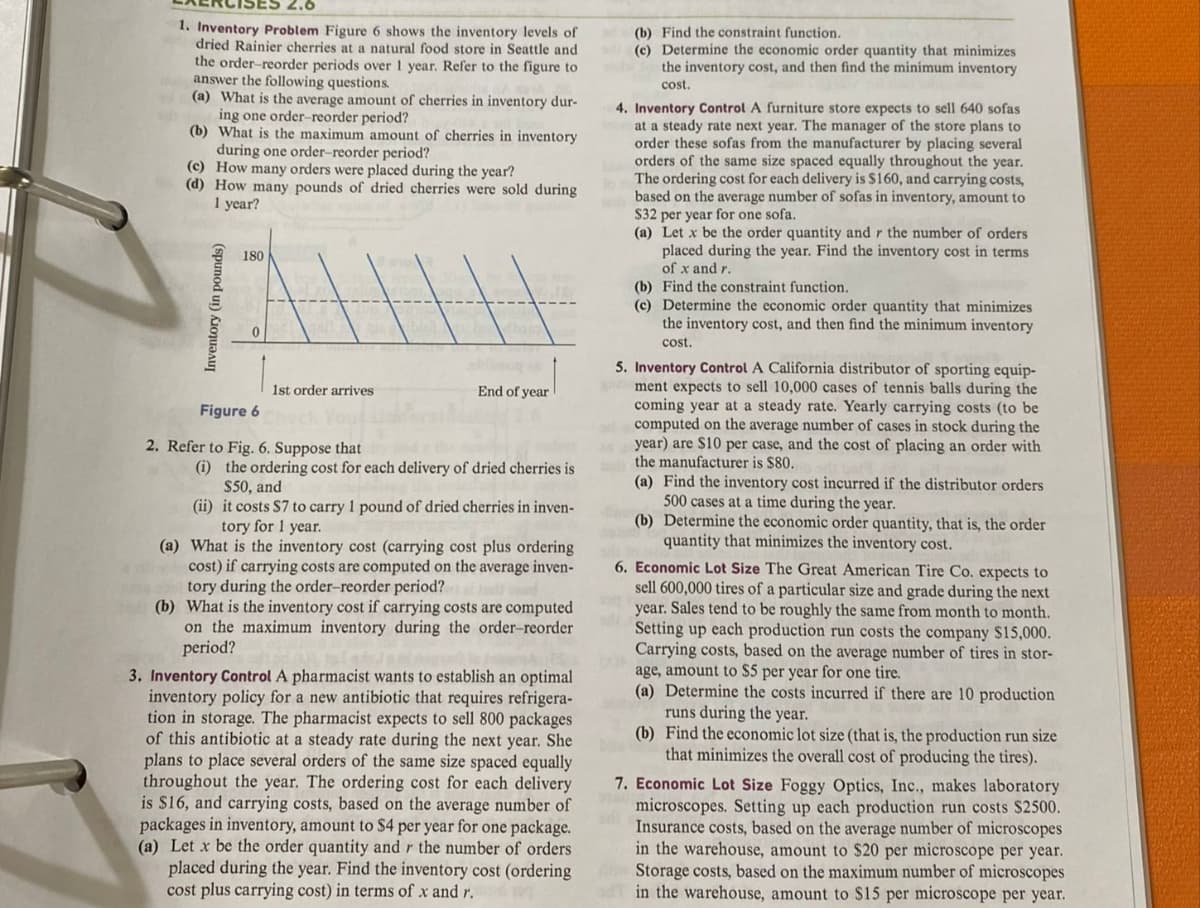

1. Inventory Problem Figure 6 shows the inventory levels of dried Rainier cherries at a natural food store in Seattle and the order-reorder periods over 1 year. Refer to the figure to answer the following questions. (a) What is the average amount of cherries in inventory dur- ing one order-reorder period? (b) What is the maximum amount of cherries in inventory during one order-reorder period? (c) How many orders were placed during the year? (d) How many pounds of dried cherries were sold during 1 year? Inventory (in pounds) 180 1st order arrives Figure 6 2. Refer to Fig. 6. Suppose that End of year (i) the ordering cost for each delivery of dried cherries is $50, and (ii) it costs $7 to carry 1 pound of dried cherries in inven- tory for 1 year. (a) What is the inventory cost (carrying cost plus ordering cost) if carrying costs are computed on the average inven- tory during the order-reorder period? (b) What is the inventory cost if carrying costs are computed on the maximum inventory during the order-reorder period? 3. Inventory Control A pharmacist wants to establish an optimal inventory policy for a new antibiotic that requires refrigera- tion in storage. The pharmacist expects to sell 800 packages of this antibiotic at a steady rate during the next year. She plans to place several orders of the same size spaced equally throughout the year. The ordering cost for each delivery is $16, and carrying costs, based on the average number of packages in inventory, amount to $4 per year for one package. (a) Let x be the order quantity and r the number of orders placed during the year. Find the inventory cost (ordering cost plus carrying cost) in terms of x and r. (b) Find the constraint function. (e) Determine the economic order quantity that minimizes the inventory cost, and then find the minimum inventory cost. 4. Inventory Control A furniture store expects to sell 640 sofas at a steady rate next year. The manager of the store plans to order these sofas from the manufacturer by placing several orders of the same size spaced equally throughout the year. The ordering cost for each delivery is $160, and carrying costs, based on the average number of sofas in inventory, amount to $32 per year for one sofa. (a) Let x be the order quantity and r the number of orders placed during the year. Find the inventory cost in terms of x and r. (b) Find the constraint function. (c) Determine the economic order quantity that minimizes the inventory cost, and then find the minimum inventory cost. 5. Inventory Control A California distributor of sporting equip- ment expects to sell 10,000 cases of tennis balls during the coming year at a steady rate. Yearly carrying costs (to be computed on the average number of cases in stock during the year) are $10 per case, and the cost of placing an order with the manufacturer is $80. (a) Find the inventory cost incurred if the distributor orders 500 cases at a time during the year. (b) Determine the economic order quantity, that is, the order quantity that minimizes the inventory cost. 6. Economic Lot Size The Great American Tire Co. expects to sell 600,000 tires of a particular size and grade during the next year. Sales tend to be roughly the same from month to month. Setting up each production run costs the company $15,000. Carrying costs, based on the average number of tires in stor- age, amount to $5 per year for one tire. (a) Determine the costs incurred if there are 10 production runs during the year. (b) Find the economic lot size (that is, the production run size that minimizes the overall cost of producing the tires). 7. Economic Lot Size Foggy Optics, Inc., makes laboratory microscopes. Setting up each production run costs $2500. Insurance costs, based on the average number of microscopes in the warehouse, amount to $20 per microscope per year. Storage costs, based on the maximum number of microscopes in the warehouse, amount to $15 per microscope per year.

1. Inventory Problem Figure 6 shows the inventory levels of dried Rainier cherries at a natural food store in Seattle and the order-reorder periods over 1 year. Refer to the figure to answer the following questions. (a) What is the average amount of cherries in inventory dur- ing one order-reorder period? (b) What is the maximum amount of cherries in inventory during one order-reorder period? (c) How many orders were placed during the year? (d) How many pounds of dried cherries were sold during 1 year? Inventory (in pounds) 180 1st order arrives Figure 6 2. Refer to Fig. 6. Suppose that End of year (i) the ordering cost for each delivery of dried cherries is $50, and (ii) it costs $7 to carry 1 pound of dried cherries in inven- tory for 1 year. (a) What is the inventory cost (carrying cost plus ordering cost) if carrying costs are computed on the average inven- tory during the order-reorder period? (b) What is the inventory cost if carrying costs are computed on the maximum inventory during the order-reorder period? 3. Inventory Control A pharmacist wants to establish an optimal inventory policy for a new antibiotic that requires refrigera- tion in storage. The pharmacist expects to sell 800 packages of this antibiotic at a steady rate during the next year. She plans to place several orders of the same size spaced equally throughout the year. The ordering cost for each delivery is $16, and carrying costs, based on the average number of packages in inventory, amount to $4 per year for one package. (a) Let x be the order quantity and r the number of orders placed during the year. Find the inventory cost (ordering cost plus carrying cost) in terms of x and r. (b) Find the constraint function. (e) Determine the economic order quantity that minimizes the inventory cost, and then find the minimum inventory cost. 4. Inventory Control A furniture store expects to sell 640 sofas at a steady rate next year. The manager of the store plans to order these sofas from the manufacturer by placing several orders of the same size spaced equally throughout the year. The ordering cost for each delivery is $160, and carrying costs, based on the average number of sofas in inventory, amount to $32 per year for one sofa. (a) Let x be the order quantity and r the number of orders placed during the year. Find the inventory cost in terms of x and r. (b) Find the constraint function. (c) Determine the economic order quantity that minimizes the inventory cost, and then find the minimum inventory cost. 5. Inventory Control A California distributor of sporting equip- ment expects to sell 10,000 cases of tennis balls during the coming year at a steady rate. Yearly carrying costs (to be computed on the average number of cases in stock during the year) are $10 per case, and the cost of placing an order with the manufacturer is $80. (a) Find the inventory cost incurred if the distributor orders 500 cases at a time during the year. (b) Determine the economic order quantity, that is, the order quantity that minimizes the inventory cost. 6. Economic Lot Size The Great American Tire Co. expects to sell 600,000 tires of a particular size and grade during the next year. Sales tend to be roughly the same from month to month. Setting up each production run costs the company $15,000. Carrying costs, based on the average number of tires in stor- age, amount to $5 per year for one tire. (a) Determine the costs incurred if there are 10 production runs during the year. (b) Find the economic lot size (that is, the production run size that minimizes the overall cost of producing the tires). 7. Economic Lot Size Foggy Optics, Inc., makes laboratory microscopes. Setting up each production run costs $2500. Insurance costs, based on the average number of microscopes in the warehouse, amount to $20 per microscope per year. Storage costs, based on the maximum number of microscopes in the warehouse, amount to $15 per microscope per year.

Purchasing and Supply Chain Management

6th Edition

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Chapter16: Lean Supply Chain Management

Section: Chapter Questions

Problem 10DQ: The chapter presented various approaches for the control of inventory investment. Discuss three...

Related questions

Question

Q1 needed to be solved correctly

By hand solution needed

Transcribed Image Text:ES 2.6

1. Inventory Problem Figure 6 shows the inventory levels of

dried Rainier cherries at a natural food store in Seattle and

the order-reorder periods over 1 year. Refer to the figure to

answer the following questions.

(a) What is the average amount of cherries in inventory dur-

ing one order-reorder period?

(b) What is the maximum amount of cherries in inventory

during one order-reorder period?

(c) How many orders were placed during the year?

(d) How many pounds of dried cherries were sold during

1 year?

Inventory (in pounds)

180

1st order arrives

Figure 6

2. Refer to Fig. 6. Suppose that

End of year

(i) the ordering cost for each delivery of dried cherries is

$50, and

(ii) it costs S7 to carry 1 pound of dried cherries in inven-

tory for 1 year.

(a) What is the inventory cost (carrying cost plus ordering

cost) if carrying costs are computed on the average inven-

tory during the order-reorder period?

(b) What is the inventory cost if carrying costs are computed

on the maximum inventory during the order-reorder

period?

3. Inventory Control A pharmacist wants to establish an optimal

inventory policy for a new antibiotic that requires refrigera-

tion in storage. The pharmacist expects to sell 800 packages

of this antibiotic at a steady rate during the next year. She

plans to place several orders of the same size spaced equally

throughout the year. The ordering cost for each delivery

is $16, and carrying costs, based on the average number of

packages in inventory, amount to $4 per year for one package.

(a) Let x be the order quantity and r the number of orders

placed during the year. Find the inventory cost (ordering

cost plus carrying cost) in terms of x and r.

(b) Find the constraint function.

(c) Determine the economic order quantity that minimizes

the inventory cost, and then find the minimum inventory

cost.

4. Inventory Control A furniture store expects to sell 640 sofas

at a steady rate next year. The manager of the store plans to

order these sofas from the manufacturer by placing several

orders of the same size spaced equally throughout the year.

The ordering cost for each delivery is $160, and carrying costs,

based on the average number of sofas in inventory, amount to

$32 per year for one sofa.

(a) Let x be the order quantity and r the number of orders

placed during the year. Find the inventory cost in terms

of x and r.

(b)

Find the constraint function.

(c) Determine the economic order quantity that minimizes

the inventory cost, and then find the minimum inventory

cost.

5. Inventory Control A California distributor of sporting equip-

ment expects to sell 10,000 cases of tennis balls during the

coming year at a steady rate. Yearly carrying costs (to be

computed on the average number of cases in stock during the

year) are $10 per case, and the cost of placing an order with

the manufacturer is $80.

(a) Find the inventory cost incurred if the distributor orders

500 cases at a time during the year.

(b) Determine the economic order quantity, that is, the order

quantity that minimizes the inventory cost.

6. Economic Lot Size The Great American Tire Co. expects to

sell 600,000 tires of a particular size and grade during the next

year. Sales tend to be roughly the same from month to month.

Setting up each production run costs the company $15,000.

Carrying costs, based on the average number of tires in stor-

age, amount to $5 per year for one tire.

(a) Determine the costs incurred if there are 10 production

runs during the year.

(b) Find the economic lot size (that is, the production run size

that minimizes the overall cost of producing the tires).

7. Economic Lot Size Foggy Optics, Inc., makes laboratory

microscopes. Setting up each production run costs $2500.

Insurance costs, based on the average number of microscopes

in the warehouse, amount to $20 per microscope per year.

Storage costs, based on the maximum number of microscopes

in the warehouse, amount to $15 per microscope per year.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps

Recommended textbooks for you

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning