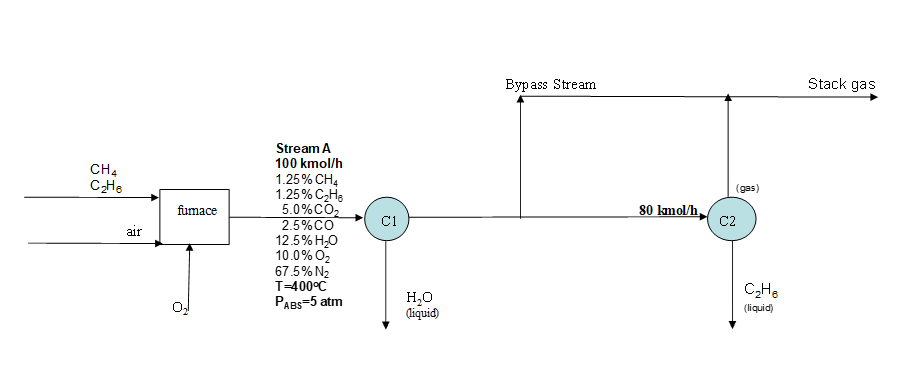

1. Natural gas usually contains a mixture of methane and ethane. Methane (CH4) and ethane (C₂H6) undergo combustion in a furnace. Air, along with another stream of pure O2, are fed to the furnace. The reactor effluent, stream A, has a total molar flow rate, composition, and T and P as shown in the schematic. The reactor effluent is fed to a 1st condenser (C1), in which all of the water (and none of the other chemicals) is condensed and removed. The remaining components are fed to a 2nd condenser (C2). However, the maximum capacity through the condenser is 80 kmol/h; the remainder of the reactor effluent bypasses the condenser. All of the ethane (and none of the other chemicals) in the feed to C2 is condensed (hence the reason that this type of natural gas is given the strange name of "natural gas liquid") and removed. The gas stream leaving C2 is mixed with the bypass stream, to form the stack gas. . Calculate the volumetric flow rate of stream A, in m³/h b. Calculate the volumetric flow rate of stream A in SCMH c. Calculate the partial pressure of O₂ in stream A.

1. Natural gas usually contains a mixture of methane and ethane. Methane (CH4) and ethane (C₂H6) undergo combustion in a furnace. Air, along with another stream of pure O2, are fed to the furnace. The reactor effluent, stream A, has a total molar flow rate, composition, and T and P as shown in the schematic. The reactor effluent is fed to a 1st condenser (C1), in which all of the water (and none of the other chemicals) is condensed and removed. The remaining components are fed to a 2nd condenser (C2). However, the maximum capacity through the condenser is 80 kmol/h; the remainder of the reactor effluent bypasses the condenser. All of the ethane (and none of the other chemicals) in the feed to C2 is condensed (hence the reason that this type of natural gas is given the strange name of "natural gas liquid") and removed. The gas stream leaving C2 is mixed with the bypass stream, to form the stack gas. . Calculate the volumetric flow rate of stream A, in m³/h b. Calculate the volumetric flow rate of stream A in SCMH c. Calculate the partial pressure of O₂ in stream A.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

complete part c only

Transcribed Image Text:CH4

C₂H6

air

fumace

0₂

Stream A

100 kmol/h

1.25% CH4

1.25% C₂H₂

5.0% CO₂

2.5%CO

12.5% H₂O

10.0% O₂

67.5% N₂

T=400°C

PABS=5 atm

C1

H₂O

(liquid)

Bypass Stream

80 kmol/h

(gas)

C2

C₂He

(liquid)

Stack gas

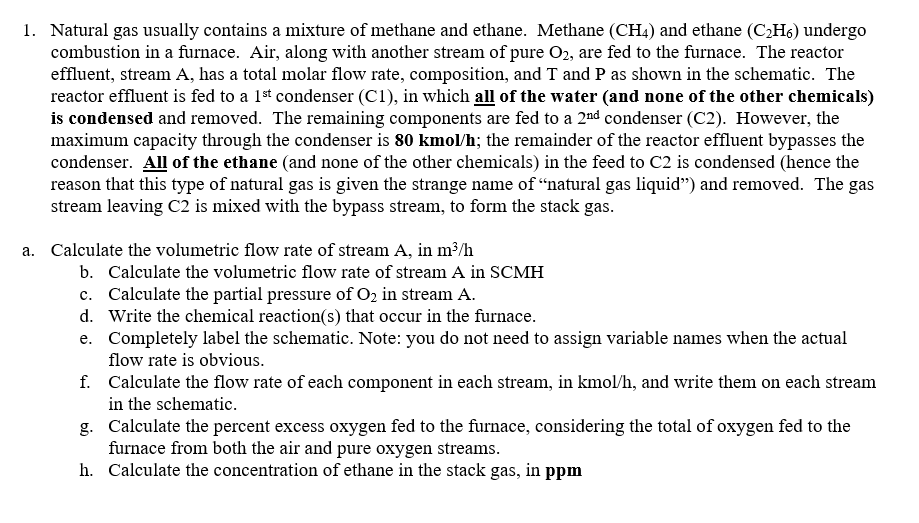

Transcribed Image Text:1. Natural gas usually contains a mixture of methane and ethane. Methane (CH4) and ethane (C₂H6) undergo

combustion in a furnace. Air, along with another stream of pure O2, are fed to the furnace. The reactor

effluent, stream A, has a total molar flow rate, composition, and T and P as shown in the schematic. The

reactor effluent is fed to a 1st condenser (C1), in which all of the water (and none of the other chemicals)

is condensed and removed. The remaining components are fed to a 2nd condenser (C2). However, the

maximum capacity through the condenser is 80 kmol/h; the remainder of the reactor effluent bypasses the

condenser. All of the ethane (and none of the other chemicals) in the feed to C2 is condensed (hence the

reason that this type of natural gas is given the strange name of "natural gas liquid") and removed. The gas

stream leaving C2 is mixed with the bypass stream, to form the stack gas.

a. Calculate the volumetric flow rate of stream A, in m³/h

b. Calculate the volumetric flow rate of stream A in SCMH

c. Calculate the partial pressure of O₂ in stream A.

d. Write the chemical reaction(s) that occur in the furnace.

e. Completely label the schematic. Note: you do not need to assign variable names when the actual

flow rate is obvious.

f. Calculate the flow rate of each component in each stream, in kmol/h, and write them on each stream

in the schematic.

g. Calculate the percent excess oxygen fed to the furnace, considering the total of oxygen fed to the

furnace from both the air and pure oxygen streams.

h. Calculate the concentration of ethane in the stack gas, in ppm

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The