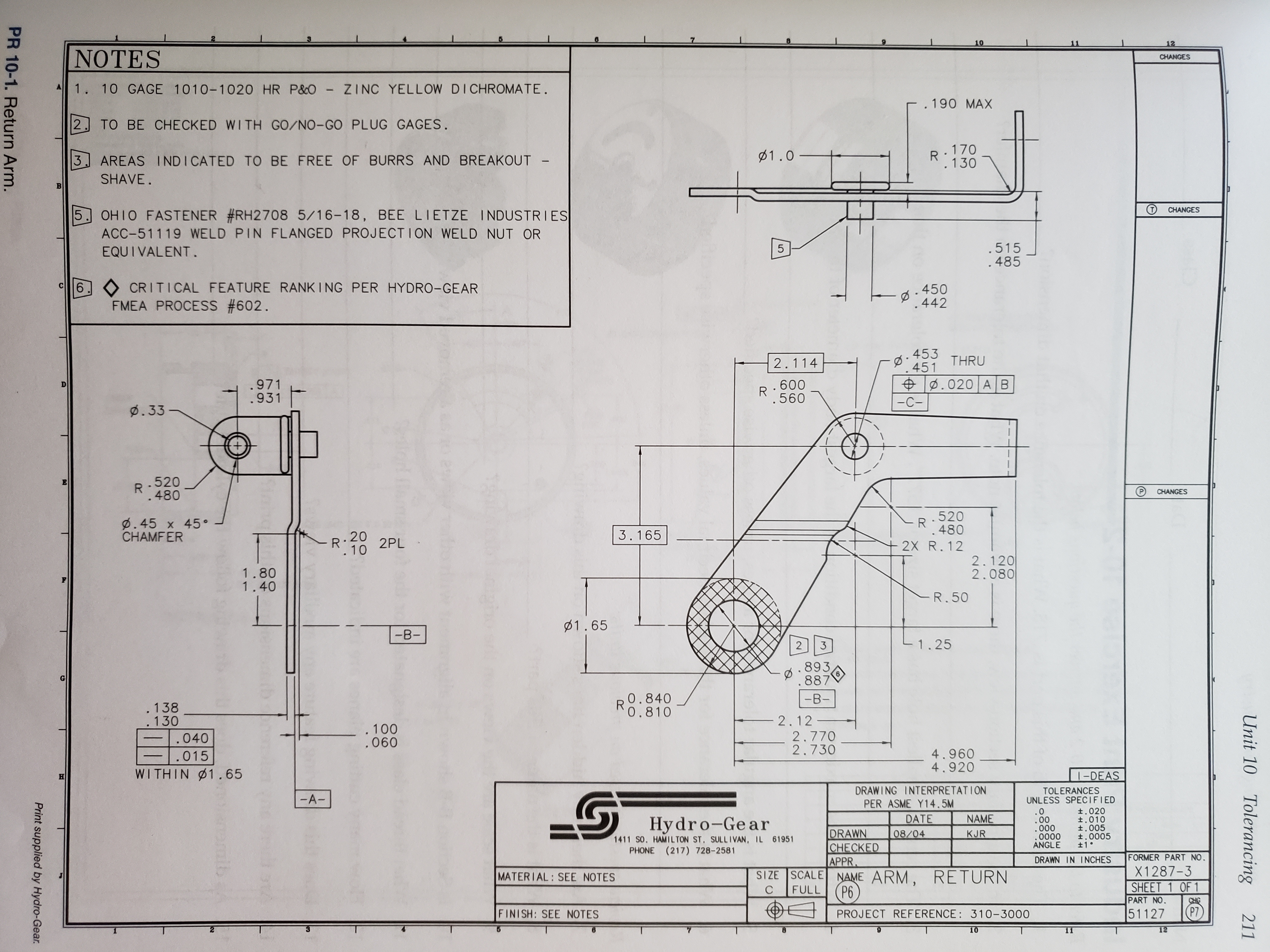

10 12 NOTES CHANGES 1. 10 GAGE 1010-1020 HR P&O ZINC YELLOW DICHROMATE. .190 MAX TO BE CHECKED WITH GO/NO-GO PLUG GAGES. 2 170 R .130 1.0 3 AREAS INDICATED TO BE FREE OF BURRS AND BREAKOUT - = SHAVE. CHANGES OHIO FASTENER #RH2708 5/16-18, BEE LIETZE INDUSTRIES ACC-51119 WELD PIN FLANGED PROJECT ION WELD NUT OR EQUI VALENT. 5 .515 .485 5 6 CRITICAL FEATURE RANKING PER HYDRO-GEAR C 450 .442 FMEA PROCESS #602 453 THRU 451 2.114 .020 A B .971 .931 .600 R 0.560 -C- Ø. 33 + .520 .480 CHANGES .520 R .480 Ø.45 x 45 CHAMFER 3.165 .20 R 2X R. 12 10 2PL 2.120 2.080 1.80 1.40 -R. 50 1.65 -B- 1.25 2 3 893 .887 0.840 R 0.810 -B- .138 .130 2.12- .100 .060 2.770 2.730 .040 4.960 4.920 -|.015 WITHIN 1. 65 1-DEAS DRAWING INTERPRETATION TOLERANCES UNLESS SPECIFIED -A- PER ASME Y14.5M t.020 t.010 t.005 t.0005 ±1 .0 .00 .000 .0000 ANGLE Hydro-Gear 1411 SO. HAMILTON ST. SULLIVAN, IL 61951 PHONE (217) 728-2581 DATE 08/04 NAME DRAWN CHECKED APPR NAME ARM, RETURN P6 KJR FORMER PART NO X1287-3 SHEET 1 OF 1 PART NO. 51127 DRAWN IN INCHES SIZE SCALE MATERIAL: SEE NOTES FULL С CHIG P7 FINISH: SEE NOTES PROJECT REFERENCE : 310-3000 12 10 11 Unit 10 Tolerancing 211 Print supplied by Hydro-Gear PR 10-1. Return Arm.

10 12 NOTES CHANGES 1. 10 GAGE 1010-1020 HR P&O ZINC YELLOW DICHROMATE. .190 MAX TO BE CHECKED WITH GO/NO-GO PLUG GAGES. 2 170 R .130 1.0 3 AREAS INDICATED TO BE FREE OF BURRS AND BREAKOUT - = SHAVE. CHANGES OHIO FASTENER #RH2708 5/16-18, BEE LIETZE INDUSTRIES ACC-51119 WELD PIN FLANGED PROJECT ION WELD NUT OR EQUI VALENT. 5 .515 .485 5 6 CRITICAL FEATURE RANKING PER HYDRO-GEAR C 450 .442 FMEA PROCESS #602 453 THRU 451 2.114 .020 A B .971 .931 .600 R 0.560 -C- Ø. 33 + .520 .480 CHANGES .520 R .480 Ø.45 x 45 CHAMFER 3.165 .20 R 2X R. 12 10 2PL 2.120 2.080 1.80 1.40 -R. 50 1.65 -B- 1.25 2 3 893 .887 0.840 R 0.810 -B- .138 .130 2.12- .100 .060 2.770 2.730 .040 4.960 4.920 -|.015 WITHIN 1. 65 1-DEAS DRAWING INTERPRETATION TOLERANCES UNLESS SPECIFIED -A- PER ASME Y14.5M t.020 t.010 t.005 t.0005 ±1 .0 .00 .000 .0000 ANGLE Hydro-Gear 1411 SO. HAMILTON ST. SULLIVAN, IL 61951 PHONE (217) 728-2581 DATE 08/04 NAME DRAWN CHECKED APPR NAME ARM, RETURN P6 KJR FORMER PART NO X1287-3 SHEET 1 OF 1 PART NO. 51127 DRAWN IN INCHES SIZE SCALE MATERIAL: SEE NOTES FULL С CHIG P7 FINISH: SEE NOTES PROJECT REFERENCE : 310-3000 12 10 11 Unit 10 Tolerancing 211 Print supplied by Hydro-Gear PR 10-1. Return Arm.

Welding: Principles and Applications (MindTap Course List)

8th Edition

ISBN:9781305494695

Author:Larry Jeffus

Publisher:Larry Jeffus

Chapter20: Shop Math And Weld Cost

Section: Chapter Questions

Problem 27R: Write the Pythagorean Theorem formula for a right triangle.

Related questions

Question

I keep being told this requires me to make my own drawing, but that is incorrect. The instructions are asking questions pertaining to the print privded. No drawing required, it is a question. Please help me solve this.

Transcribed Image Text:10

12

NOTES

CHANGES

1. 10 GAGE 1010-1020 HR P&O ZINC YELLOW DICHROMATE.

.190 MAX

TO BE CHECKED WITH GO/NO-GO PLUG GAGES.

2

170

R

.130

1.0

3

AREAS INDICATED TO BE FREE OF BURRS AND BREAKOUT -

=

SHAVE.

CHANGES

OHIO FASTENER #RH2708 5/16-18, BEE LIETZE INDUSTRIES

ACC-51119 WELD PIN FLANGED PROJECT ION WELD NUT OR

EQUI VALENT.

5

.515

.485

5

6

CRITICAL FEATURE RANKING PER HYDRO-GEAR

C

450

.442

FMEA PROCESS #602

453 THRU

451

2.114

.020 A B

.971

.931

.600

R

0.560

-C-

Ø. 33

+

.520

.480

CHANGES

.520

R

.480

Ø.45 x 45

CHAMFER

3.165

.20

R

2X R. 12

10 2PL

2.120

2.080

1.80

1.40

-R. 50

1.65

-B-

1.25

2 3

893

.887

0.840

R

0.810

-B-

.138

.130

2.12-

.100

.060

2.770

2.730

.040

4.960

4.920

-|.015

WITHIN 1. 65

1-DEAS

DRAWING INTERPRETATION

TOLERANCES

UNLESS SPECIFIED

-A-

PER ASME Y14.5M

t.020

t.010

t.005

t.0005

±1

.0

.00

.000

.0000

ANGLE

Hydro-Gear

1411 SO. HAMILTON ST. SULLIVAN, IL 61951

PHONE (217) 728-2581

DATE

08/04

NAME

DRAWN

CHECKED

APPR

NAME ARM, RETURN

P6

KJR

FORMER PART NO

X1287-3

SHEET 1 OF 1

PART NO.

51127

DRAWN IN INCHES

SIZE SCALE

MATERIAL: SEE NOTES

FULL

С

CHIG

P7

FINISH: SEE NOTES

PROJECT REFERENCE : 310-3000

12

10

11

Unit 10

Tolerancing

211

Print supplied by Hydro-Gear

PR 10-1. Return Arm.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning