2) Atmospheric air (79% N₂ and 21% O2 on a molar basis) is to be distilled at 1 atm to produce 98% N2 (top product) and 98% O2 (bottom product). A total condenser will be used. Assuming the reflux ratio R = 2, determine the number of theoretical stages required (using the graph below) if the feed is, a) liquid at its bubble-point, b) vapour at its dew point. 100 90 80 70 8 MOL, PER CENT NITROGEN IN VAPOUR 20 10 10 20 30 40 MOL PER CENT NITROGEN IN LIQUID 50 60 70 80 90 100

2) Atmospheric air (79% N₂ and 21% O2 on a molar basis) is to be distilled at 1 atm to produce 98% N2 (top product) and 98% O2 (bottom product). A total condenser will be used. Assuming the reflux ratio R = 2, determine the number of theoretical stages required (using the graph below) if the feed is, a) liquid at its bubble-point, b) vapour at its dew point. 100 90 80 70 8 MOL, PER CENT NITROGEN IN VAPOUR 20 10 10 20 30 40 MOL PER CENT NITROGEN IN LIQUID 50 60 70 80 90 100

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

ans Q2a): 6 theoretical plates plus the reboiler; feed on stage 4 b) 6 or 7 theoretical plates plus reboiler - depends on how you draw the diagram; feed on stage 4 or 5

feedback attached to help with ques

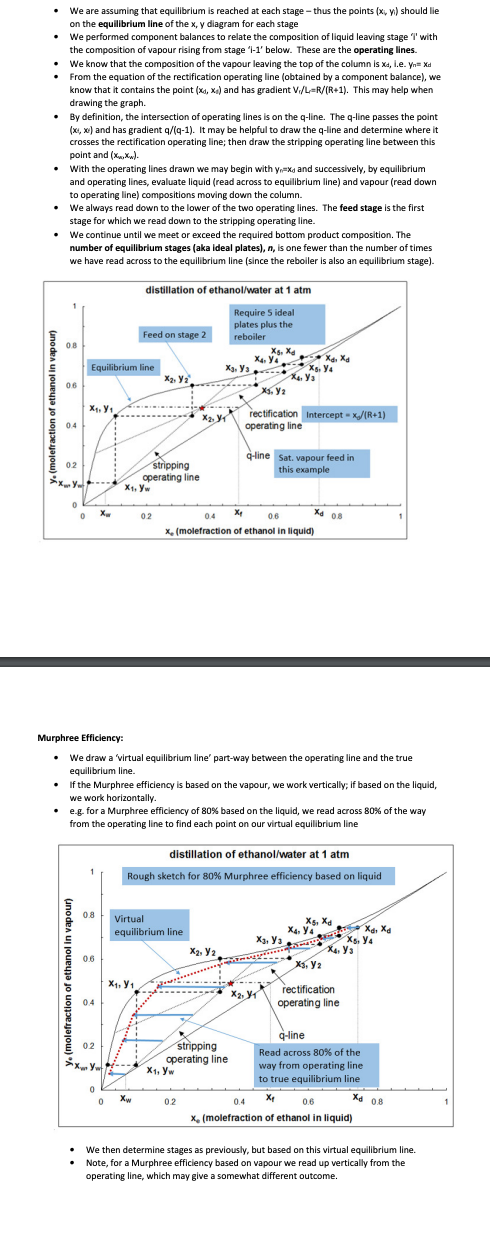

Transcribed Image Text:We are assuming that equilibrium is reached at each stage - thus the points (x, y) should lie

on the equilibrium line of the x, y diagram for each stage

We performed component balances to relate the composition of liquid leaving stage 'I' with

the composition of vapour rising from stage 'i-1' below. These are the operating lines

We know that the composition of the vapour leaving the top of the column is xa, i.e. Yn= Xd

From the equation of the rectification operating line (obtained by a component balance), we

know that it contains the point (x, x₁) and has gradient V₁/L-R/(R+1). This may help when

drawing the graph.

By definition, the intersection of operating lines is on the q-line. The q-line passes the point

(x,x) and has gradient q/(q-1). It may be helpful to draw the q-line and determine where it

crosses the rectification operating line; then draw the stripping operating line between this

point and (XX).

With the operating lines drawn we may begin with y₁x and successively, by equilibrium

and operating lines, evaluate liquid (read across to equilibrium line) and vapour (read down

to operating line) compositions moving down the column.

We always read down to the lower of the two operating lines. The feed stage is the first

stage for which we read down to the stripping operating line.

We continue until we meet or exceed the required bottom product composition. The

number of equilibrium stages (aka ideal plates), n, is one fewer than the number of times

we have read across to the equilibrium line (since the reboiler is also an equilibrium stage).

0.8

0.6

0.4

0.2

=x-Y

0

0

X₁,Y₁

.

Equilibrium line

0.8

Xa

0.6

04

02

*XmYw

distillation of ethanol/water at 1 atm

Require 5 ideal

plates plus the

reboiler

0

Feed on stage 2

X₁, Yw

stripping

operating line

X₁, Y₁

X2, Y2

0.2

Xw

Murphree Efficiency:

We draw a 'virtual equilibrium line' part-way between the operating line and the true

equilibrium line.

If the Murphree efficiency is based on the vapour, we work vertically; if based on the liquid,

we work horizontally.

• e.g. for a Murphree efficiency of 80% based on the liquid, we read across 80% of the way

from the operating line to find each point on our virtual equilibrium line

Virtual

equilibrium line

X₂X₁

0.4

X₁

0.6

x, (molefraction of ethanol in liquid)

X5, Xd

X3. Y3X₁Y3

Уз

X₁,Y₂

X2, Y2

*******

to X

Xs. Y4

distillation of ethanol/water at 1 atm

Rough sketch for 80% Murphree efficiency based on liquid

X1, Yw

0.2

rectification Intercept -x/(R+1)

operating line

..

stripping

operating line

q-line Sat. vapour feed in

this example

Xa 08

X₂, X₁

X5, Xd

X4, Y4

X3, 3X5. Y4

X3, Y2

rectification

operating line

Xd, Xd

q-line

Read across 80% of the

way from operating line.

to true equilibrium line

0.4

X₁ 0.6

x, (molefraction of ethanol in liquid)

Xd 0.8

We then determine stages as previously, but based on this virtual equilibrium line.

Note, for a Murphree efficiency based on vapour we read up vertically from the

operating line, which may give a somewhat different outcome.

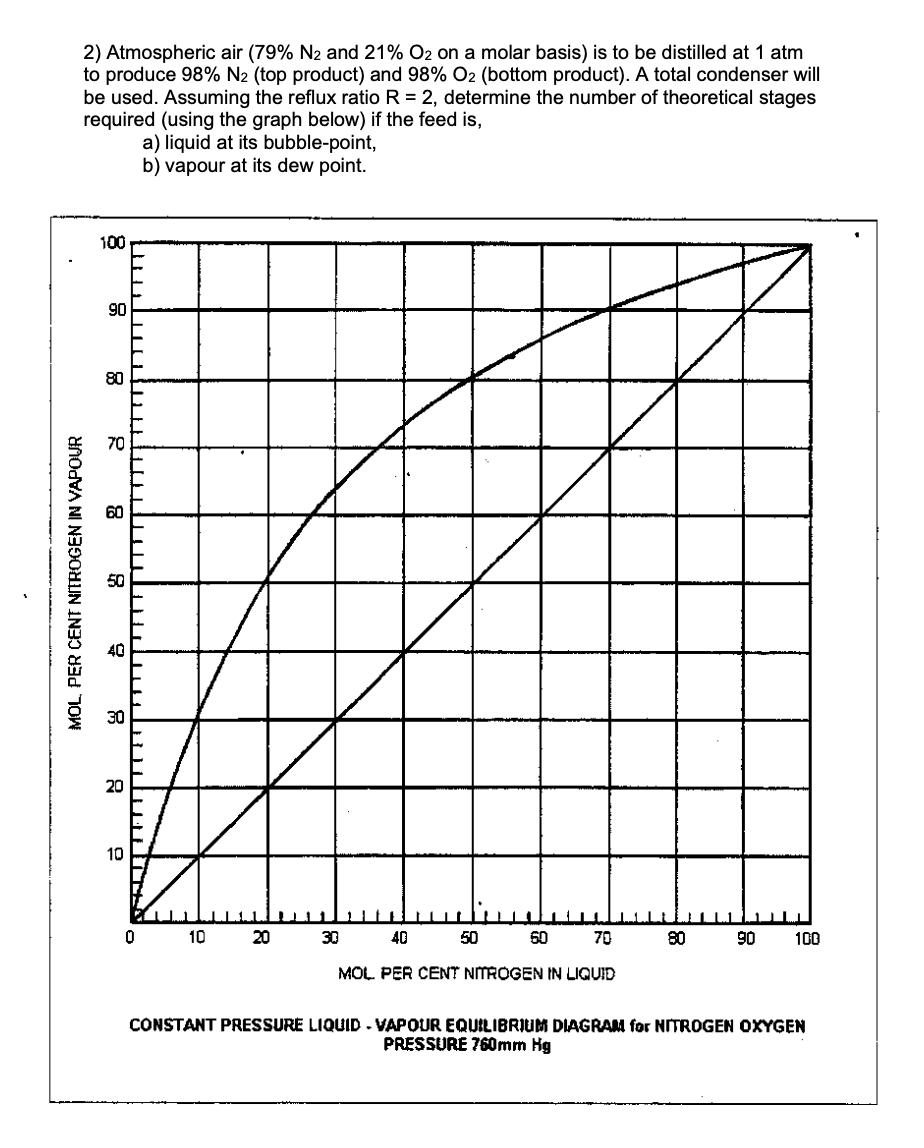

Transcribed Image Text:2) Atmospheric air (79% N₂ and 21% O₂ on a molar basis) is to be distilled at 1 atm

to produce 98% N2 (top product) and 98% O2 (bottom product). A total condenser will

be used. Assuming the reflux ratio R = 2, determine the number of theoretical stages

required (using the graph below) if the feed is,

a) liquid at its bubble-point,

b) vapour at its dew point.

MOL PER CENT NITROGEN IN VAPOUR

100

90

80

70

60

40

30

20

10

MU

0

10

20

30

40

70

MOL PER CENT NITROGEN IN LIQUID

50

60

80

90

100

CONSTANT PRESSURE LIQUID - VAPOUR EQUILIBRIUM DIAGRAM for NITROGEN OXYGEN

PRESSURE 760mm Hg

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 3 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The