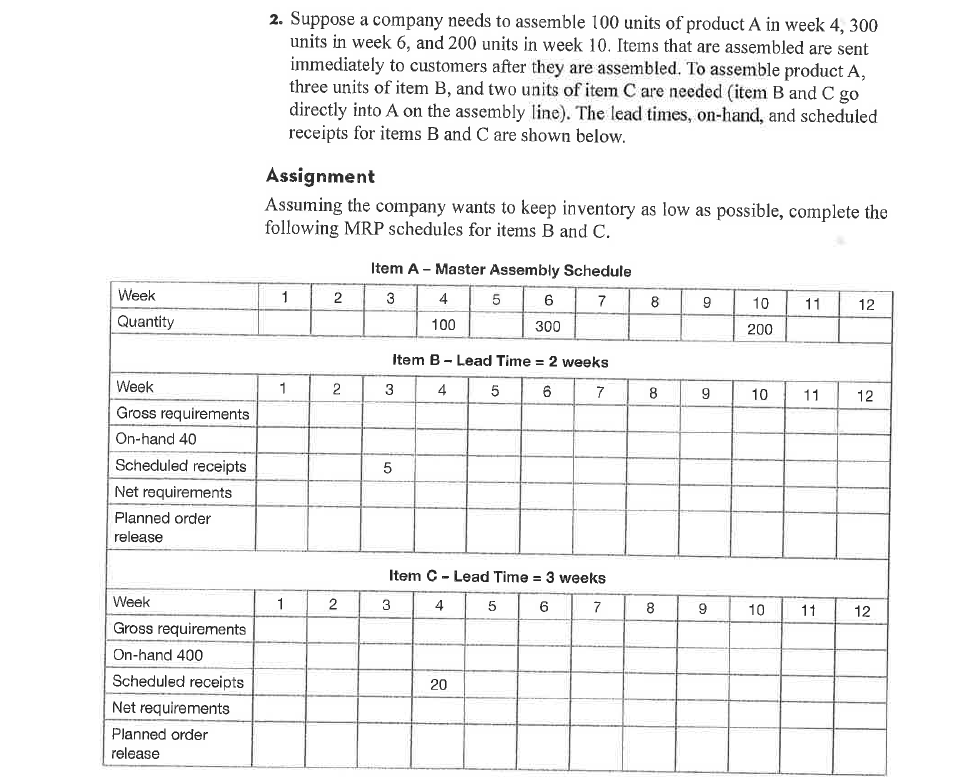

2. Suppose a company needs to assemble 100 units of product A in week 4, 300 units in week 6, and 200 units in week 10. Items that are assembled are sent immediately to customers after they are assembled. To assemble product A, three units of item B, and two units of item C are needed (item B and C go directly into A on the assembly line). The lead times, on-hand, and scheduled receipts for items B and C are shown below. Assignment Assuming the company wants to keep inventory as low as possible, complete the following MRP schedules for items B and C. Item A- Master Assembly Schedule Week 3 4 10 11 12 Quantity 100 300 200 Item B - Lead Time = 2 weeks Week 3 5 10 11 12 Gross requirements On-hand 40 Scheduled receipts 5 Net requirements Planned order release Item C - Lead Time = 3 weeks Week 2 3 4 6 10 11 12 Gross requirements On-hand 400 Scheduled receipts 20 Net requirements Planned order release

Recruitment in Business Communication

The process of discovering and employing the finest and most competent individual for a work opportunity fairly and cost-effectively is referred to as recruitment in human resource management. It is also known as the act of locating potential individuals and motivating and pushing them to compete for positions within a firm. It is a complete process with a complete life cycle that originates with the assessment of the organizational requirements in relation to the position and continues with the employee's engagement with the organization.

Recruitment

Recruitment is the most important part of Human Resource Management (HRM) which is done by HR (Human Resources) of a company, firm, or industry. To understand the policy, HR needs to understand and analyze the requirement of a profile who can fit into the position as per the company’s objectives and goals. Recruitment involves shortlisting, hiring, and analyzing candidates' skills along with experience and qualifications and comparing them with the organization's requirements or job profile. The objective of the recruitment process is to find the right candidate for the right job.

I am not even sure I understand how to begin to this question and to fill out this sheet.

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 1 images