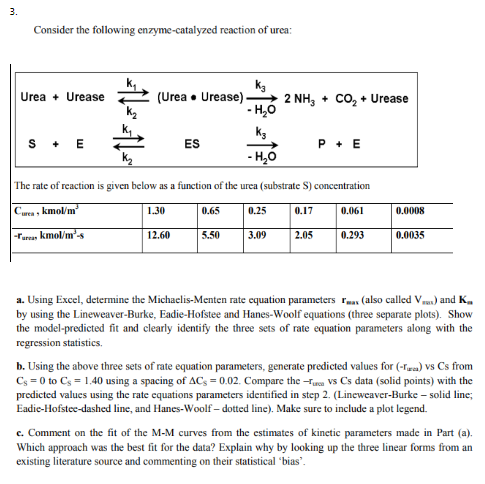

3. Consider the following enzyme-catalyzed reaction of urea Urea + Urease (Urea. Urease)-> 2 NH, + CO2-urease ES The rate of reaction is given below as a function of the urea (substrate S) concentration Curea, kmol/m .30 0.65 0.25 0.17 0.061 0.0008 urea kmol/m-s 12.60 5.50 3.09 2.05 0.293 0,0035 a. Using Excel, determine the Michaelis-Menten rate equation parameters ra (also called V and K. by using the Lineweaver-Burke, Eadie-Hofstee and Hanes-Woolf equations (three separate plots). Show the model-predicted fit and clearly identify the three sets of rate equation parameters along with the regression statistics b. Using the above three sets of rate equation parameters, generate predicted values for ) vs Cs from Cs-0 to Cs-1.40 using a spacing of ACs-0.02. Compare the -S Cs data (solid points) with the predicted values using the rate equations parameters identified in step 2. (Lineweaver-Burke - solid line; Eadie-Hofstee-dashed line, and Hanes-Woolf- dotted line). Make sure to include a plot legend. e. Comment on the fit of the M-M curves from the estimates of kinetic parameters made in Part (a). Which approach was the best fit for the data? Explain why by looking up the three linear forms from an existing literature source and commenting on their statistical 'bias

3. Consider the following enzyme-catalyzed reaction of urea Urea + Urease (Urea. Urease)-> 2 NH, + CO2-urease ES The rate of reaction is given below as a function of the urea (substrate S) concentration Curea, kmol/m .30 0.65 0.25 0.17 0.061 0.0008 urea kmol/m-s 12.60 5.50 3.09 2.05 0.293 0,0035 a. Using Excel, determine the Michaelis-Menten rate equation parameters ra (also called V and K. by using the Lineweaver-Burke, Eadie-Hofstee and Hanes-Woolf equations (three separate plots). Show the model-predicted fit and clearly identify the three sets of rate equation parameters along with the regression statistics b. Using the above three sets of rate equation parameters, generate predicted values for ) vs Cs from Cs-0 to Cs-1.40 using a spacing of ACs-0.02. Compare the -S Cs data (solid points) with the predicted values using the rate equations parameters identified in step 2. (Lineweaver-Burke - solid line; Eadie-Hofstee-dashed line, and Hanes-Woolf- dotted line). Make sure to include a plot legend. e. Comment on the fit of the M-M curves from the estimates of kinetic parameters made in Part (a). Which approach was the best fit for the data? Explain why by looking up the three linear forms from an existing literature source and commenting on their statistical 'bias

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Transcribed Image Text:3.

Consider the following enzyme-catalyzed reaction of urea

Urea + Urease

(Urea. Urease)-> 2 NH, + CO2-urease

ES

The rate of reaction is given below as a function of the urea (substrate S) concentration

Curea, kmol/m

.30

0.65

0.25

0.17

0.061

0.0008

urea kmol/m-s

12.60

5.50

3.09

2.05

0.293

0,0035

a. Using Excel, determine the Michaelis-Menten rate equation parameters ra (also called V and K.

by using the Lineweaver-Burke, Eadie-Hofstee and Hanes-Woolf equations (three separate plots). Show

the model-predicted fit and clearly identify the three sets of rate equation parameters along with the

regression statistics

b. Using the above three sets of rate equation parameters, generate predicted values for ) vs Cs from

Cs-0 to Cs-1.40 using a spacing of ACs-0.02. Compare the -S Cs data (solid points) with the

predicted values using the rate equations parameters identified in step 2. (Lineweaver-Burke - solid line;

Eadie-Hofstee-dashed line, and Hanes-Woolf- dotted line). Make sure to include a plot legend.

e. Comment on the fit of the M-M curves from the estimates of kinetic parameters made in Part (a).

Which approach was the best fit for the data? Explain why by looking up the three linear forms from an

existing literature source and commenting on their statistical 'bias

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 8 steps with 8 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The