3. Heat Loss from Longitudinal Fin. A longitudinal aluminum fin, as shown in Fig. 15.8-3a (k = 230 W/m K), is attached to a copper tube having of 0.04 m. The length of the fin is 0.080 m and the thickness is 3 mm. The tube base is held at 450 K and the external surrounding air at 300 K has a convective coefficient of 25 W/m2 K. Calculate the fin efficiency and the heat loss from the fin per 1.0 m of length. an outside radius AM .a a 0.039 B = 0.70 for nonviscous liquids where D = diameter of the vessel in m, Ds = diameter of the rotating shaft in m, v = the axial flow velocity of liquid in m/s, N = the agitator speed in rev/s, and nB on the agitator. Data cover a region of axial flow velocities of 0.076 to 0.38 m/min and rota- tional speeds of 100 to 750 rpm. Typical overall heat-transfer coefficients in food applications are U = 1700 W/m2 K the number of blades (300 btu/h ft F) for cooling margarine with NH3, 2270 (400) for heating applesauce with steam, 1420 (250) for chilling shortening with NH3, and 2270 (400) for cooling cream with water (B6). 15.8C Extended Surface or Finned Exchangers 1. Introduction. The use of fins or extended surfaces on the outside of a heat-exchanger pipe wall to give relatively high heat-transfer coefficients in the exchanger is quite common. An automobile radiator is such a device, where hot water passes inside through a bank of tubes and loses heat to the air. On the outside of the tubes, extended surfaces receive heat from the tube walls and transmit it to the air by forced convection. Two common types of fins attached to the outside of a tube wall are shown in Fig. 15.8-3. In Fig, 15.8-3a, there are a number of longitudinal fins spaced around the tube wall and the direction of gas flow is parallel to the axis of the tube. In Fig. 15.8-3b, the gas flows normally to the tubes containing many circular or transverse fins. fin fin 058-13) L tube S10 tube (b) (a) Figure 15.8-3. Two common types of fins on a section of circular tube: (a) longitudinal fin, (b) circular or transverse fin. Part 1 Transport Processes: Momentum, Heat, and Mass 431

3. Heat Loss from Longitudinal Fin. A longitudinal aluminum fin, as shown in Fig. 15.8-3a (k = 230 W/m K), is attached to a copper tube having of 0.04 m. The length of the fin is 0.080 m and the thickness is 3 mm. The tube base is held at 450 K and the external surrounding air at 300 K has a convective coefficient of 25 W/m2 K. Calculate the fin efficiency and the heat loss from the fin per 1.0 m of length. an outside radius AM .a a 0.039 B = 0.70 for nonviscous liquids where D = diameter of the vessel in m, Ds = diameter of the rotating shaft in m, v = the axial flow velocity of liquid in m/s, N = the agitator speed in rev/s, and nB on the agitator. Data cover a region of axial flow velocities of 0.076 to 0.38 m/min and rota- tional speeds of 100 to 750 rpm. Typical overall heat-transfer coefficients in food applications are U = 1700 W/m2 K the number of blades (300 btu/h ft F) for cooling margarine with NH3, 2270 (400) for heating applesauce with steam, 1420 (250) for chilling shortening with NH3, and 2270 (400) for cooling cream with water (B6). 15.8C Extended Surface or Finned Exchangers 1. Introduction. The use of fins or extended surfaces on the outside of a heat-exchanger pipe wall to give relatively high heat-transfer coefficients in the exchanger is quite common. An automobile radiator is such a device, where hot water passes inside through a bank of tubes and loses heat to the air. On the outside of the tubes, extended surfaces receive heat from the tube walls and transmit it to the air by forced convection. Two common types of fins attached to the outside of a tube wall are shown in Fig. 15.8-3. In Fig, 15.8-3a, there are a number of longitudinal fins spaced around the tube wall and the direction of gas flow is parallel to the axis of the tube. In Fig. 15.8-3b, the gas flows normally to the tubes containing many circular or transverse fins. fin fin 058-13) L tube S10 tube (b) (a) Figure 15.8-3. Two common types of fins on a section of circular tube: (a) longitudinal fin, (b) circular or transverse fin. Part 1 Transport Processes: Momentum, Heat, and Mass 431

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter10: Heat Exchangers

Section: Chapter Questions

Problem 10.8P:

10.8 The heat transfer coefficient of a copper tube (1.9-cm II) and 2.3-em OD) is on the inside...

Related questions

Question

Transcribed Image Text:3. Heat Loss from Longitudinal Fin. A longitudinal aluminum fin, as shown in

Fig. 15.8-3a (k = 230 W/m K), is attached to a copper tube having

of 0.04 m. The length of the fin is 0.080 m and the thickness is 3 mm. The tube base is

held at 450 K and the external surrounding air at 300 K has a convective coefficient

of 25 W/m2 K. Calculate the fin efficiency and the heat loss from the fin per 1.0 m of

length.

an outside radius

AM

.a

Transcribed Image Text:a 0.039 B = 0.70

for nonviscous liquids

where D = diameter of the vessel in m, Ds = diameter of the rotating shaft in m, v = the axial

flow velocity of liquid in m/s, N = the agitator speed in rev/s, and nB

on the agitator. Data cover a region of axial flow velocities of 0.076 to 0.38 m/min and rota-

tional speeds of 100 to 750 rpm.

Typical overall heat-transfer coefficients in food applications are U = 1700 W/m2 K

the number of blades

(300 btu/h ft F) for cooling margarine with NH3, 2270 (400) for heating applesauce with

steam, 1420 (250) for chilling shortening with NH3, and 2270 (400) for cooling cream with

water (B6).

15.8C Extended Surface or Finned Exchangers

1. Introduction. The use of fins or extended surfaces on the outside of a heat-exchanger

pipe wall to give relatively high heat-transfer coefficients in the exchanger is quite common.

An automobile radiator is such a device, where hot water passes inside through a bank of

tubes and loses heat to the air. On the outside of the tubes, extended surfaces receive heat

from the tube walls and transmit it to the air by forced convection.

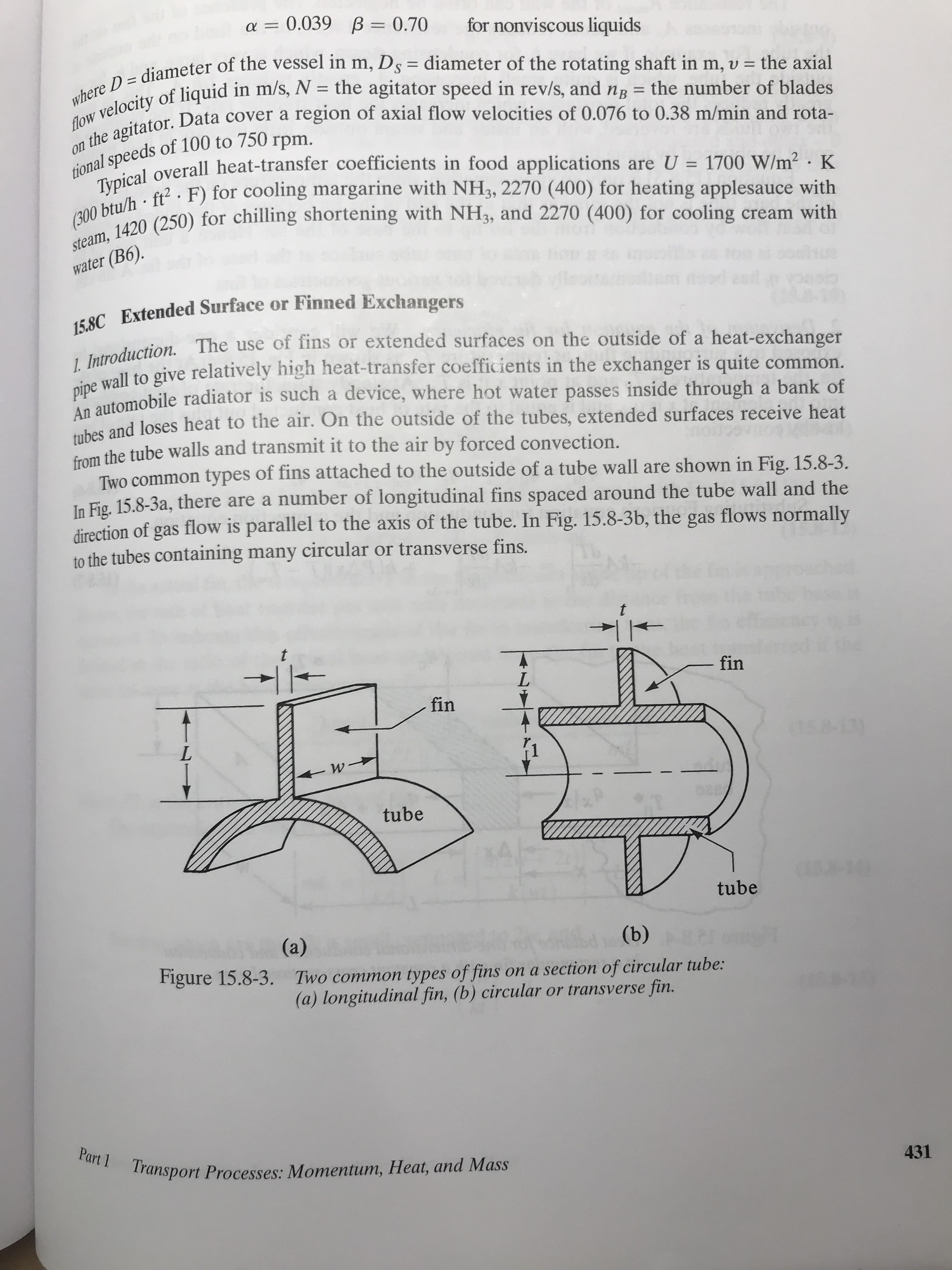

Two common types of fins attached to the outside of a tube wall are shown in Fig. 15.8-3.

In Fig, 15.8-3a, there are a number of longitudinal fins spaced around the tube wall and the

direction of gas flow is parallel to the axis of the tube. In Fig. 15.8-3b, the gas flows normally

to the tubes containing many circular or transverse fins.

fin

fin

058-13)

L

tube

S10

tube

(b)

(a)

Figure 15.8-3.

Two common types of fins on a section of circular tube:

(a) longitudinal fin, (b) circular or transverse fin.

Part 1 Transport Processes: Momentum, Heat, and Mass

431

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 6 steps with 4 images

Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning