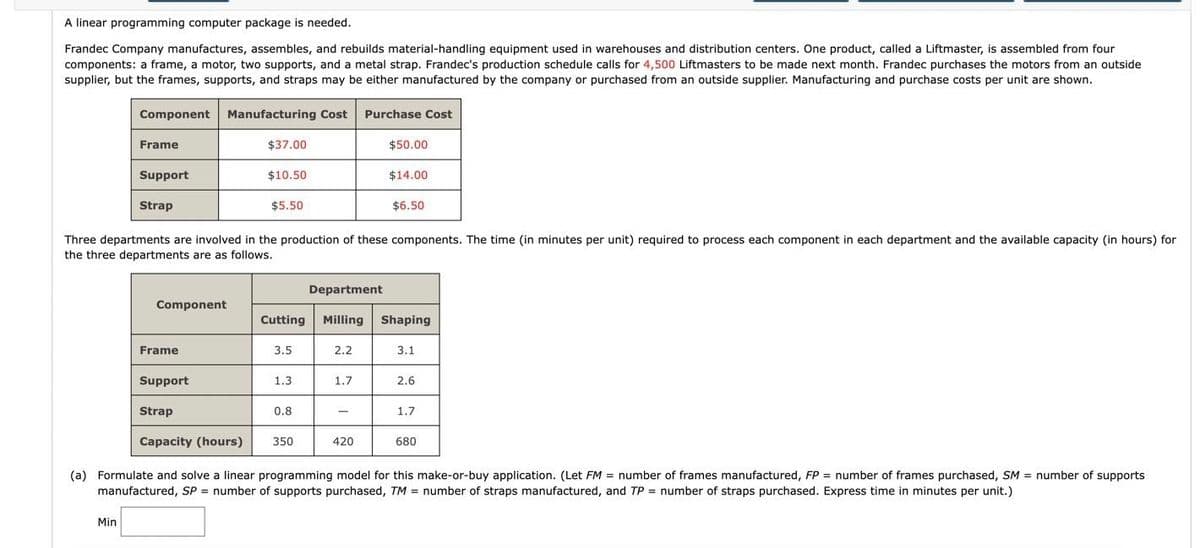

(a) Formulate and solve a linear programming model for this make-or-buy application. (Let FM = number of frames manufactured, FP = number of frames purchased, SM = number of supports manufactured, SP = number of supports purchased, TM= number of straps manufactured, and TP = number of straps purchased. Express time in minutes per unit.) Min

Q: How would you determine which orders have not yet been shipped to the customer?

A: To find out which orders haven't been delivered to the client yet, we can see the Order table. The…

Q: An engineering plant has developed the accompanying supply, demand, cost and inventory data. The…

A: Find the given details below: Given details: Period 1 2 3 Demand 650 700 900 Regular time…

Q: PharmaPlus operates a chain of 30 pharmacies. The pharmacies are staffed by licensed pharmacists and…

A: Given data is Current no. of pharmacists = 85 Current no. of technicians = 175 Required employees =…

Q: Briefly

A: Introduction: Inventory control consists of the steps a business takes to acquire, store, and…

Q: Classify the following types of processes as continuous, assembly line, batch, job shop, or project:…

A: Continuous process: A method that relies on continuous flow rather than batch, intermittent, or…

Q: The following is a table of activities associated with a project at Rafay Ishfaq's software firm in…

A: Given data is

Q: operation definition

A: Here is your solution:

Q: Namibia: Walvis Bay Port is now a regional logistic hub The new container terminal at the Namibian…

A: Common core components of Transport: A transport system has the following core…

Q: The following is a table of activities associated with a project at Rafay Ishfaq's software firm in…

A: Project crashing is a process which helps to reduce the total completion time using nodes and…

Q: Compare and contrast between intra and inter-organisational connections that exist within a supply…

A: The supply chain is an important concept in business and it refers to the sequence of activities…

Q: Harlen Industries Limited has a simple forecasting model whose forecast demand has been plotted…

A: In this question, we have the table data for an 8 periods duration, for each period, we have actual…

Q: Toys from the world, for the world 5 years ago, while conducting an online search for a toy for her…

A: Transport Packaging refers to materials used in addition to Primary Packaging to accommodate the…

Q: 3. Hoosier Gasoline Company, or HoosCo as they are known, produces two blends of gasoline, regular…

A: The question is to find the quantity of each type of gasoline that should be produced to maximize…

Q: a) Labor productivity per labor hour for these tires = tires/labor hour (round your response to two…

A: Productivity is the relationship between the volume of the input and output that is calculated in…

Q: Case study: container shortage challenges Unexpected events have resulted in a global container…

A: The given case study is about the situation of container shortage due to the pandemic. The shipping…

Q: You work for the Brad's Nailer Company which manufactures three types of nailers: a pneumatic model,…

A: From the given information, there are three types of nailers, Pneumatic, ProLine and Cordless.…

Q: Name two financial incentives that could be used to encourage businesses to investigate and…

A: The two financial incentives could be used to encourage businesses to investigate and implement…

Q: 9 MPS parent X has planned order releases of 30 in weeks 2 and 4. Given the following roduct tree,…

A: Ans) For each X , 1 Y needed: and For each Y, 2 Z needed: Formula:

Q: Activity Event Immediate 1 2 3 14 5 |6 17 8 development of a new product in your organization. 19 10…

A: Total expected time = (optimistic time +4*most likely time + pessimistic time)/ 6

Q: Calculate the ES, EF, LS, and LF times and the slack for each activity in the figure below, and…

A: A network diagram related to the project shows the sequence of the task that is performed to…

Q: A mortgage service office has the following four activities involved in approving a loan…

A: Capacity indicating the maximum possible production unit based on the 1005 usage in a specific…

Q: Discuss the golden rule level of capital using a diagram and explain why it is beneficial?

A: The meaning of the "Golden Rule of Capital Accumulation" At the very least, the Solow model…

Q: A group is planning to back the production of a new musical at Lusaka Playhouse. It would cost K100…

A: NOTE: We are allowed to do one question only. Decision trees are a popular and powerful way to…

Q: A local restaurateur, Cho Senn, is considering three options for his new Asian fusi restaurant.…

A: Given data, For Option A, the annual fixed cost=42500 the variable cost per customer=3.45 For…

Q: The five risk management strategies should be identified and succinctly explained.

A: Risk management refers to controlling risk or preparing ways to eliminate, avoid, or reduce the risk…

Q: Determine the expected value of the contribution

A: The expected value of a decision tree is the sum of the expected values of all the nodes.

Q: .A 45 kW rated solar power system has its power output and the Solar irradiance on the PV system…

A: Find the Given details below: Given details: Solar Irradiance on the PV system (KW/m2) Power…

Q: Describe how project management software packages can help with project scheduling. Please respond…

A: Project management software:- Resources can be planned, organised, and managed with the aid of…

Q: Electronics Company has received a much greater number of queries in recent months. DVD players for…

A: Problem: According to the lawsuit, DVD players manufactured by Electronic Companies have a drawer…

Q: The management of the Just Like Home Restaurant has asked you to analyze some of its processes. One…

A: The total chart for this process is given as follows: The chart has given all the pieces of…

Q: From a technical perspective, how should the threat be classified? What kinds of dangers do people…

A: With the development of information and communication technologies and increasing accessibility to…

Q: (2). A company produces tables at its two factories A and B. The next three months, the company must…

A: Month Demand 1 300 2 400 3 500 The cost details: Labor hours Cost Factory A 1.5 hrs…

Q: An operation has a scrap rate of 15%. As a result, 102 sellable pieces per hour are produced. a.…

A: Scrap rate = 15% Better production = (100%-15%) Better production = 85% or 0.85 Hourly production =…

Q: Café Michigan's manager, Gary Stark, suspects that demand for mocha latte coffees depends on the…

A: Given, Price Number Sold 2.5 765 3.6 515 2.1 975 4.1 245 3.1 315 4.05 490

Q: A multinational corporation is considering the investment opportunities shown in the table below.…

A:

Q: As you develop your project closeout documents, you begin to review the project deliverables and…

A: Here, we are developing the documents for the project closeout process, so, we need to review the…

Q: min 8x1+6x2 subject to 4x1+2x2 ≥ 20 -6x1+4x2 ≤ 12 X1+X2 ≥ 6 X1, X2 20

A: "Since you have asked multiple question, we will solve the first question for you. If you want any…

Q: 1. Describe the NBS supply chain and How critical is stock-outs in the operations of UK’s NBS?

A: Every drop of donated blood should be properly and effectively kept in hospital blood banks,…

Q: An electronic store uses continuous review policy to manage the inventory of its high selling…

A: Annual demand(D) = 4000*2*52 = 4,16,000 units Unit price = 7000 AED Ordering cost(S) = 80,000 AED…

Q: 2. Four products are processed sequentially on three machines in an aircraft maintenance workshop.…

A: Decision Variable: Suppose-P1 is the no. of units of product 1P2 is the no. of units of product…

Q: 140 Friday Using this table above, solve for Mean Absolute Deviation (MAD) xample 9.6568->9.66

A: Absolute error = |actual-forecast| MAD = Average |actual-forecast|

Q: Solve the following LP by using Excel. State the Optimal Solution and the Objective Function Value.…

A: Linear programming is a mathematical technique that is commonly used in operations management…

Q: Why was Frederick Winslow Taylor known as the father of scientific management.

A: Frederick Winslow Taylor is known as a father of scientific management who invent the scientific…

Q: What is productivity and why is it important? Who is primarily responsible for productivity in an…

A: Productivity is a very important factor for organizations to consider when trying to increase their…

Q: 3.8 Given the following data, calculate how many units are available to promise. There are zero…

A: Week 1 2 3 4 5 6 Customer order 21 0 17 8 0 3 Inventory on hand 0 MPS 30 0…

Q: f. Given e, what is the maximum number of orders waiting to be picked? Maximum number of orders…

A: The maximum output for any process is equal to the output at the bottlenck workstation

Q: The Westchester Chamber of Commerce periodically sponsors public service seminars and programs.…

A:

Q: ENUMERATE 10 POSITIVE RESULTS YOU CAN EXPECT IF INVENTORY WILL BE PROPERLY OR EFFECTIVELY MANAGED.…

A: Inventory management refers to planning and controlling the goods in an optimal manner such that the…

Q: A careful analysis of the cost of operating an automobile was conducted by accounting manager Dia…

A: Solution Model y = 4000+0.20x Annual cost = y Miles drive = x Given that, x = 15000

Q: Please provide formula and answer

A: Given data is Product Cookies Cupcakes Muffins Donuts Demand in dozens 600 500 400 300…

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 6 images

- A linear programming computer package is needed. Frandec Company manufactures, assembles, and rebuilds material-handling equipment used in warehouses and distribution centers. One product, called a Liftmaster, is assembled from four components: a frame, a motor, two supports, and a metal strap. Frandec's production schedule calls for 5,500 Liftmasters to be made next month. Frandec purchases the motors from an outside supplier, but the frames, supports, and straps may be either manufactured by the company or purchased from an outside supplier. Manufacturing and purchase costs per unit are shown. Component Manufacturing Cost Purchase Cost Frame $39.00 $52.00 Support $12.50 $16.00 Strap $7.50 $8.50 Three departments are involved in the production of these components. The time (in minutes per unit) required to process each component in each department and the available capacity (in hours) for the three departments are as follows. Component Department Cutting Milling…A linear programming computer package is needed. Frandec Company manufactures, assembles, and rebuilds material-handling equipment used in warehouses and distribution centers. One product, called a Liftmaster, is assembled from four components: a frame, a motor, two supports, and a metal strap. Frandec's production schedule calls for 5,500 Liftmasters to be made next month. Frandec purchases the motors from an outside supplier, but the frames, supports, and straps may be either manufactured by the company or purchased from an outside supplier. Manufacturing and purchase costs per unit are shown. Component Manufacturing Cost Purchase Cost Frame $39.00 $52.00 Support $12.50 $16.00 Strap $7.50 $8.50 Three departments are involved in the production of these components. The time (in minutes per unit) required to process each component in each department and the available capacity (in hours) for the three departments are as follows. Component Department Cutting Milling…A linear programming computer package is needed. Frandec Company manufactures, assembles, and rebuilds material-handling equipment used in warehouses and distribution centers. One product, called a Liftmaster, is assembled from four components: a frame, a motor, two supports, and a metal strap. Frandec's production schedule calls for 4,500 Liftmasters to be made next month. Frandec purchases the motors from an outside supplier, but the frames, supports, and straps may be either manufactured by the company or purchased from an outside supplier. Manufacturing and purchase costs per unit are shown. Component Manufacturing Cost Purchase Cost Frame $39.00 $52.00 Support $12.50 $16.00 Strap $7.50 $8.50 Three departments are involved in the production of these components. The time (in minutes per unit) required to process each component in each department and the available capacity (in hours) for the three departments are as follows. Component Department Cutting Milling…

- Patz Company produces two types of machine parts: Part A and Part B, with unit contribution margins of $400 and $800, respectively. Assume initially that Patz can sell all that is produced of either component. Part A requires two hours of assembly, and B requires five hours of assembly. The firm has 400 assembly hours per week. What if market conditions are such that Patz can sell at most 100 units of Part A and 80 units of Part B? Express the objective function with its associated constraints for this case. Objective function: Max Z = $400 A + $800 B Assembly-hour constraint fill in the blank 7 A + fill in the blank 8 B ≤ fill in the blank 9 Demand constraint for Part A A ≤ fill in the blank 10 Demand constraint for Part B B ≤ fill in the blank 11 Identify the optimal mix and its associated total contribution margin.Component A $fill in the blank 12 units Component B $fill in the blank 13 units Total contribution $fill in the blank 14each Distributors packages and distributes industrial supplies. A standard shipment can be packaged in a class A container, a class K container, or a class T container. A single class A container yields a profit of $10; a class K container, a profit of $8; and a class T container, a profit of $12. Each shipment prepared requires a certain amount of packing material and a certain amount of time. Formulate and solve this problem using LP software. Resources Needed per Standard Shipment Class of Container Packing Material (pounds) Packing Time (hours) A 2 2 K 1 6 T 3 4 Total amount of resource available per week 120 pounds 210 hours Hugh Leach, head of the firm, must decide the optimal number of each class of container to pack each week. He is bound by the previously mentioned resource restrictions but also decides that he must keep his 6 full-time packers employed all 210 hours (6 workers × 35 hours)…La Jolla Beverage Products is considering producing a wine cooler that would be a blend of a white wine, a rose wine, and fruit juice. To meet taste specifications, the wine cooler must consist of at least 45% white wine, at least 25% and no more than 35% rose, and exactly 25% fruit juice. La Jolla purchases the wine from local wineries and the fruit juice from a processing plant in San Francisco. For the current production period, 10000 gallons of white wine and 6500 gallons of rose wine can be purchased; an unlimited amount of fruit juice can be ordered. The costs for the wine are $1 per gallon for the white and $1.5 per gallon for the rose; the fruit juice can be purchased for $0.5 per gallon. La Jolla Beverage Products can sell all of the wine cooler it can produce for $2.5 per gallon. Is the cost of the wine and fruit juice a sunk cost or a relevant cost in this situation? Formulate a linear program to determine the blend of the three ingredients that will maximize the total…

- Noah Yobs, who has $75,400 of AGI (solely from wages) before considering rental activities, has $67,860 of losses from a real estate rental activity in which he actively participates. He also actively participates in another real estate rental activity from which he has $37,700 of income. He has other passive activity income of $24,128. a. What amount of rental loss can Noah use to offset active or portfolio income in the current year? 6,032 Compute Noah’s AGI on Form 1040 [pages 1 and 2; also complete Schedule 1 (Form 1040)] for the current year. Use the minus sign to indicate a loss.A linear programming computer package is needed. The Westchester Chamber of Commerce periodically sponsors public service seminars and programs. Currently, promotional plans are under way for this year's program. Advertising alternatives include television, radio, and online. Audience estimates, costs, and maximum media usage limitations are as shown. Constraint Television Radio Online Audience per advertisement 400,000 72,000 160,000 Cost per advertisement $2,000 $300 $600 Maximum media usage 10 20 10 To ensure a balanced use of advertising media, radio advertisements must not exceed 50% of the total number of advertisements authorized. In addition, television should account for at least 10% of the total number of advertisements authorized. If the promotional budget is limited to $20,500, By how much would audience contact increase if an extra $100 were allocated to the promotional budget? (Round your answer to the nearest whole number.)A company manufactures both mountain bikes and trail bikes. The cost of materials for a mountain bike is $60, and the cost of materials for a trail bike is $40. The cost of labor to manufacture a mountain bike is $80, and the cost of labor to manufacture a trail bike is $60. During a week in which the company has budgeted $1,800 for materials and $2,500 for labor, how many mountain bikes does the company plan to manufacture? mountain bikes

- A small candy shop is preparing for the holiday season. The owner must decide how many bags of deluxe mix and how many bags of standard mix of Peanut/Raisin Delite to put up. The deluxe mix has .70 pounds of raisins and .30 pounds of peanuts, and the standard mix has 0.45 pounds of raisins and 0.55 pounds of peanuts per bag. The shop has 90 pounds of raisins and 60 pounds of peanuts to work with. Peanuts cost $0.6 per pound and raisins cost $1.55 per pound. The deluxe mix will sell for $2.9 for a one-pound bag, and the standard mix will sell for $2.55 for a one-pound bag. The owner estimates that no more than 110 bags of one type can be sold. a. If the goal is to maximize profits, how many bags of each type should be prepared? b. What is the expected profit?A small candy shop is preparing for the holiday season. The owner must decide how many bags of Deluxe Mix and how many bags of Standard Mix of Peanut/Raisin Delite to put up. The Deluxe Mix has 2/3 pound raisins and 1/3 pound peanuts, and the Standard Mix has 1/2 pound raisins and 1/2 pound peanuts per bag. The shop has 90 pounds of raisins and 60 pounds of peanuts to work with. Peanuts cost $0.60 per pound and raisins cost $1.50 per pound. The Deluxe Mix will sell for $2.90 per pound, and the Standard Mix will ell for $2.55 per pound. The owner estimates that no more than 110 bags of one type can be sold. If the goal is to maximize profits, how many bags of each type should be prepared?A producer has three products, A, B, and C, which are composed from many of the same raw materials and subassemblies by the same skilled workforce. Each unit of product A uses 15 units of Raw Material X, one Purge System Subassembly, one Case, one Power Cord, three Labour Hours in the Assembly Department, and one Labour Hour in the Finishing Department. Each unit of product B uses 10 units of Raw Material X, five units of Raw Material Y, two Purge System Subassemblies, one Case, one Power cord, five Labour Hours in the Assembly Department, and 90 minutes in the Finishing Department. Each unit of product C uses five units of Raw Material X, 25 units of Raw Material Y, two Purge System Subassemblies, one Case, a Power Cord, seven Labour Hours in the Assembly Department, and Three Labour Hours in the Finishing Department. Labour between the Assembly and Finishing departments is not transferable, but workers within each department work on any of the three products. There are three…