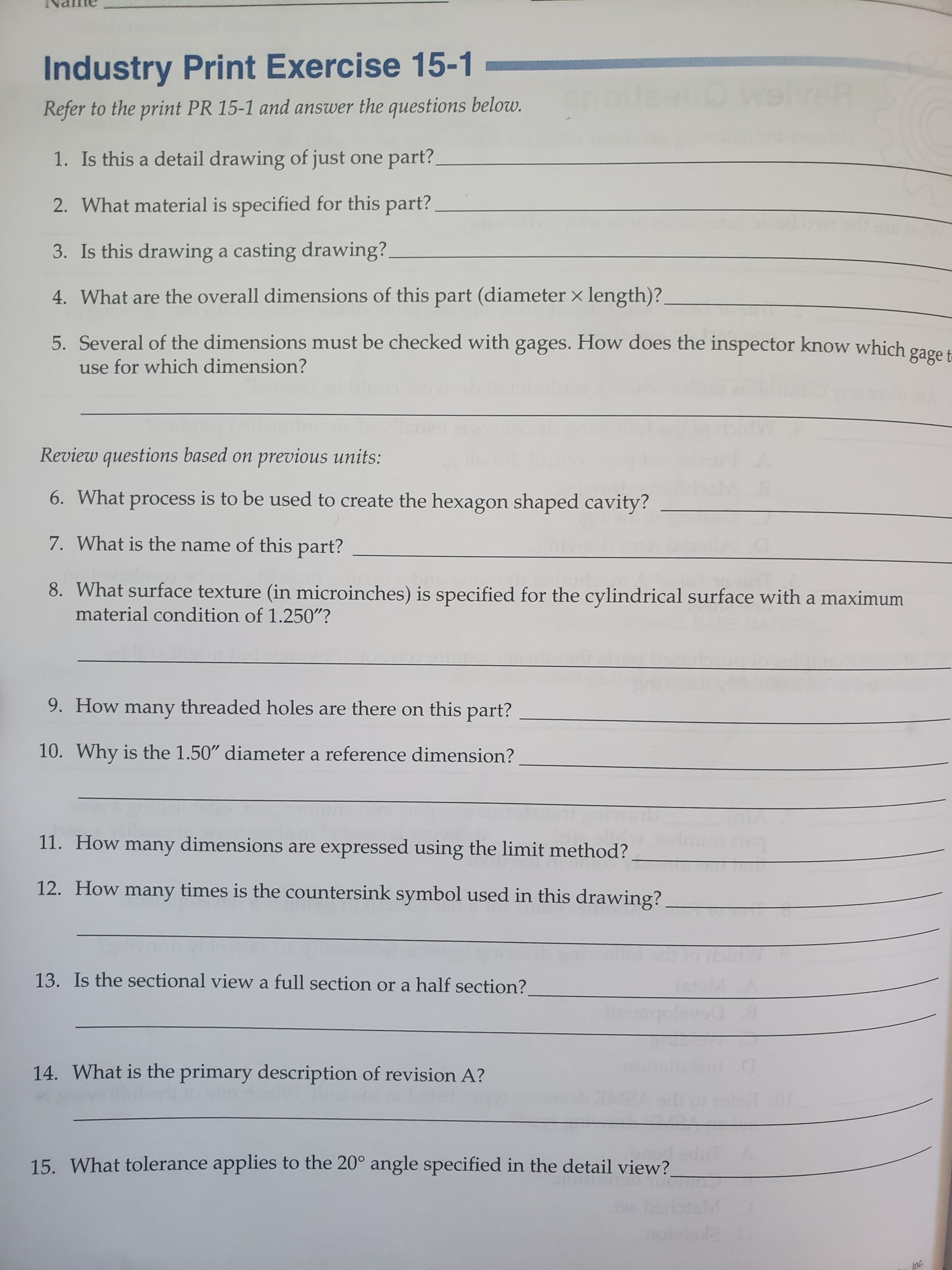

Industry Print Exercise 15-1 ein Refer to the print PR 15-1 and answer the questions below. 1. Is this a detail drawing of just one part? 2. What material is specified for this part? 3. Is this drawing a casting drawing? 4. What are the overall dimensions of this part (diameter x length)? 5. Several of the dimensions must be checked with gages. How does the inspector know which gage t for which dimension? Review questions based on previous units: 6. What process is to be used to create the hexagon shaped cavity? 7. What is the name of this part? 8. What surface texture (in microinches) is specified for the cylindrical surface with a maximum material condition of 1.250"? 9. How many threaded holes are there on this part? 10. Why is the 1.50" diameter a reference dimension? 11. How many dimensions are expressed using the limit method? 12. How many times is the countersink symbol used in this drawing? 13. Is the sectional view a full section or a half section? 14. What is the primary description of revision A? 15. What tolerance applies to the 20° angle specified in the detail view? Inc Detail Drawings Unit 15 317 10 1.530 0.906 BORE PRIOR TO BROACHING IS PERMISSIBLE .093 .362 .212 (11 12 .150 90 X 1.063 3 .575 6 15' 32/ 752 .750 13) 7 8 .885 .880 1.250 1.245 НЕХ (01.50) 1.020 $1.325 32/ BLEND 032 015 SEE VIEW "A" 20° 60° 4 .094 2 .966 .956 .812 dool Tla oooom VIEW "A" SCALE: 2:1 99 5 1.740 1 1/2 RD BRASS ROD RED 11550-417 701240 A-CHANGES 1-GAGES COLOR CODE NUMBER MATERIAL DESCRIPTION SPECIFICATION DRAWN ENGINEER REGO® CRYO-FLOW PRODUCTS T. TICKLE P. KEANE CHECKED APPROVED BURLINGTON, N.C. 27215 D. WILLIAMS J. OLSEN ORIGINAL DATE PLOT GENERATED: THIS DRAWING IS ECII PROPRIETARY INFORMATION ALL RIGHTS OF DESIGN OR INVENTION ARE RESERVED UNLESS OTHERWISE SPECIFIED: 05/10 09/28 t 015 t 02 t .005 t .0005 t 1° TITLE: REVISIONS 2 PL. DEC. 3 PL DEC. 4 PL DEC. ANGLES REV & MF BONNET SLEEVE A195, 04/15 REV&REDRAWN A CONCENTRICITY .010 FIM FINISH 125 MAX REMOVE BURRS, BREAK SHARP EDGES R.015 MAX INTERPRET DIMENSIONS & TOLERANCES AW ASME Y14.5M-1994 DWG SIZE DRAWING NO A 009550-3 SCALE (1:1) Print supplied by RegO Cryo-Flow Products. PR 15-1. Bonnet Sleeve Copyright Goodheart-Willcox Co., Inc.

Industry Print Exercise 15-1 ein Refer to the print PR 15-1 and answer the questions below. 1. Is this a detail drawing of just one part? 2. What material is specified for this part? 3. Is this drawing a casting drawing? 4. What are the overall dimensions of this part (diameter x length)? 5. Several of the dimensions must be checked with gages. How does the inspector know which gage t for which dimension? Review questions based on previous units: 6. What process is to be used to create the hexagon shaped cavity? 7. What is the name of this part? 8. What surface texture (in microinches) is specified for the cylindrical surface with a maximum material condition of 1.250"? 9. How many threaded holes are there on this part? 10. Why is the 1.50" diameter a reference dimension? 11. How many dimensions are expressed using the limit method? 12. How many times is the countersink symbol used in this drawing? 13. Is the sectional view a full section or a half section? 14. What is the primary description of revision A? 15. What tolerance applies to the 20° angle specified in the detail view? Inc Detail Drawings Unit 15 317 10 1.530 0.906 BORE PRIOR TO BROACHING IS PERMISSIBLE .093 .362 .212 (11 12 .150 90 X 1.063 3 .575 6 15' 32/ 752 .750 13) 7 8 .885 .880 1.250 1.245 НЕХ (01.50) 1.020 $1.325 32/ BLEND 032 015 SEE VIEW "A" 20° 60° 4 .094 2 .966 .956 .812 dool Tla oooom VIEW "A" SCALE: 2:1 99 5 1.740 1 1/2 RD BRASS ROD RED 11550-417 701240 A-CHANGES 1-GAGES COLOR CODE NUMBER MATERIAL DESCRIPTION SPECIFICATION DRAWN ENGINEER REGO® CRYO-FLOW PRODUCTS T. TICKLE P. KEANE CHECKED APPROVED BURLINGTON, N.C. 27215 D. WILLIAMS J. OLSEN ORIGINAL DATE PLOT GENERATED: THIS DRAWING IS ECII PROPRIETARY INFORMATION ALL RIGHTS OF DESIGN OR INVENTION ARE RESERVED UNLESS OTHERWISE SPECIFIED: 05/10 09/28 t 015 t 02 t .005 t .0005 t 1° TITLE: REVISIONS 2 PL. DEC. 3 PL DEC. 4 PL DEC. ANGLES REV & MF BONNET SLEEVE A195, 04/15 REV&REDRAWN A CONCENTRICITY .010 FIM FINISH 125 MAX REMOVE BURRS, BREAK SHARP EDGES R.015 MAX INTERPRET DIMENSIONS & TOLERANCES AW ASME Y14.5M-1994 DWG SIZE DRAWING NO A 009550-3 SCALE (1:1) Print supplied by RegO Cryo-Flow Products. PR 15-1. Bonnet Sleeve Copyright Goodheart-Willcox Co., Inc.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need answers for problems 10, 11, and 12 pertaining to the print provided.

Transcribed Image Text:Industry Print Exercise 15-1

ein

Refer to the print PR 15-1 and answer the questions below.

1. Is this a detail drawing of just one part?

2. What material is specified for this part?

3. Is this drawing a casting drawing?

4. What are the overall dimensions of this part (diameter x length)?

5. Several of the dimensions must be checked with gages. How does the inspector know which gage t

for which dimension?

Review questions based on previous units:

6. What process is to be used to create the hexagon shaped cavity?

7. What is the name of this part?

8. What surface texture (in microinches) is specified for the cylindrical surface with a maximum

material condition of 1.250"?

9. How many threaded holes are there on this part?

10. Why is the 1.50" diameter a reference dimension?

11. How many dimensions are expressed using the limit method?

12. How many times is the countersink symbol used in this drawing?

13. Is the sectional view a full section or a half section?

14. What is the primary description of revision A?

15. What tolerance applies to the 20° angle specified in the detail view?

Inc

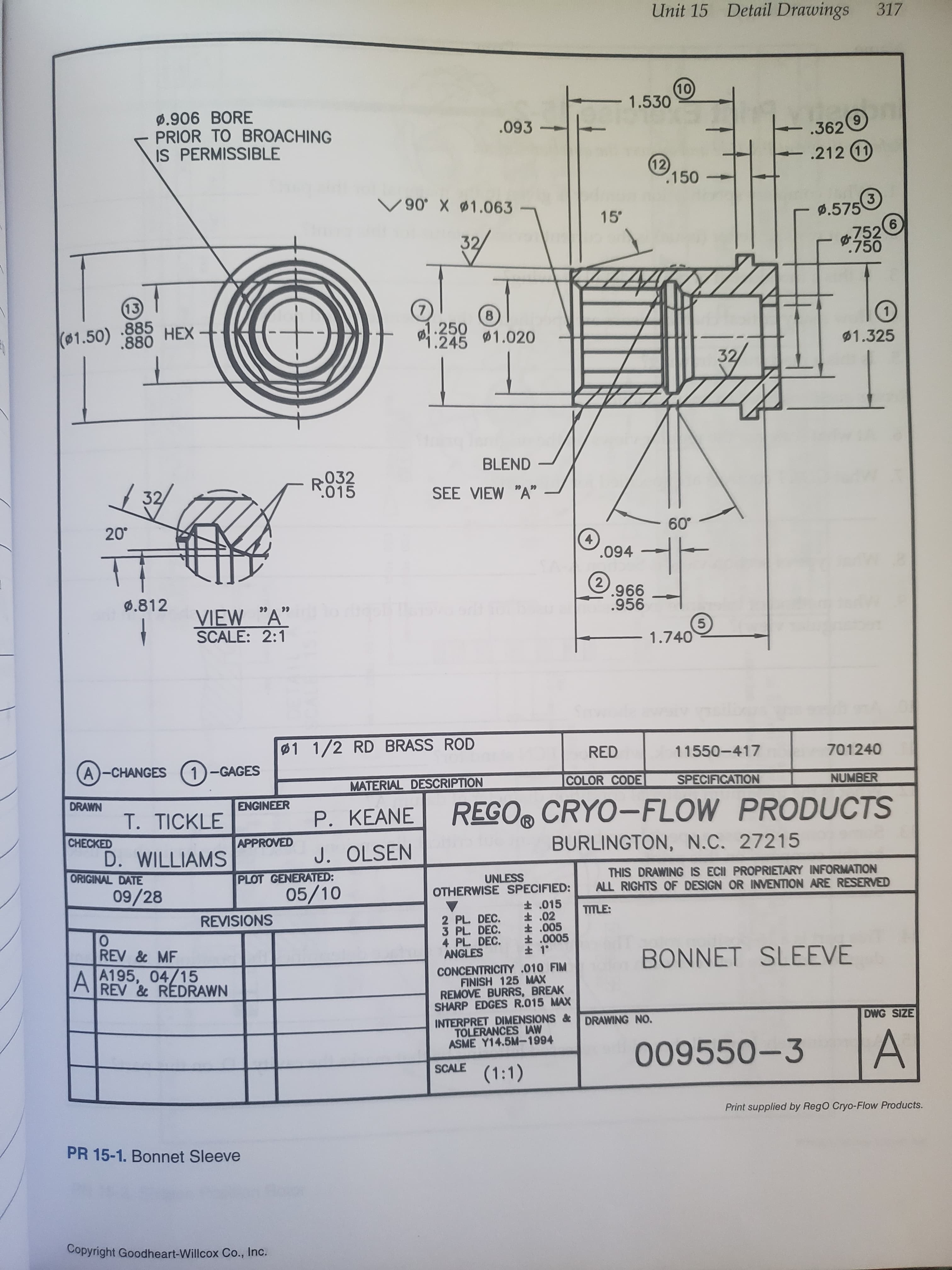

Transcribed Image Text:Detail Drawings

Unit 15

317

10

1.530

0.906 BORE

PRIOR TO BROACHING

IS PERMISSIBLE

.093

.362

.212 (11

12

.150

90 X 1.063

3

.575

6

15'

32/

752

.750

13)

7

8

.885

.880

1.250

1.245

НЕХ

(01.50)

1.020

$1.325

32/

BLEND

032

015

SEE VIEW "A"

20°

60°

4

.094

2

.966

.956

.812

dool Tla oooom

VIEW "A"

SCALE: 2:1

99

5

1.740

1 1/2 RD BRASS ROD

RED

11550-417

701240

A-CHANGES

1-GAGES

COLOR CODE

NUMBER

MATERIAL DESCRIPTION

SPECIFICATION

DRAWN

ENGINEER

REGO® CRYO-FLOW PRODUCTS

T. TICKLE

P. KEANE

CHECKED

APPROVED

BURLINGTON, N.C. 27215

D. WILLIAMS

J. OLSEN

ORIGINAL DATE

PLOT GENERATED:

THIS DRAWING IS ECII PROPRIETARY INFORMATION

ALL RIGHTS OF DESIGN OR INVENTION ARE RESERVED

UNLESS

OTHERWISE SPECIFIED:

05/10

09/28

t 015

t 02

t .005

t .0005

t 1°

TITLE:

REVISIONS

2 PL. DEC.

3 PL DEC.

4 PL DEC.

ANGLES

REV & MF

BONNET SLEEVE

A195, 04/15

REV&REDRAWN

A

CONCENTRICITY .010 FIM

FINISH 125 MAX

REMOVE BURRS, BREAK

SHARP EDGES R.015 MAX

INTERPRET DIMENSIONS &

TOLERANCES AW

ASME Y14.5M-1994

DWG SIZE

DRAWING NO

A

009550-3

SCALE

(1:1)

Print supplied by RegO Cryo-Flow Products.

PR 15-1. Bonnet Sleeve

Copyright Goodheart-Willcox Co., Inc.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY