is carried out isothermally in a continuous flow reactor. Calculate both the CSTR and the PFR reactor volumes (if it is possible) necessary to consurme 96% of S (ie. S = 0.04 *S) when the entering volumetric flow rate is at a constant 12 L/hr. Assume the reaction rate -s follows normal Michaelis-Menten kinetics (the product formation step is slow and rate limiting) where the substrate binds with the enzyme to form complex ES. Assume that there is no immobilization or inhibition effects present. a. So-1.5 mol/L and Vmax-4.50 mol/(hr L) and Km- 0.0300 mol/L b. S,-0.030 mol/L and Vmax = 0.10 mol/(hr*L) and Km = 0.095 mol/L c. So= 0.90 mol/L and Vmax 0.10 mol/(hr*L) and Km = 0.0750 mol/L lfitismotpossibletodetermine thereactor vol esforthedata given above, l tthe remai ingvariables that are needed to determine the reactor volumes.

is carried out isothermally in a continuous flow reactor. Calculate both the CSTR and the PFR reactor volumes (if it is possible) necessary to consurme 96% of S (ie. S = 0.04 *S) when the entering volumetric flow rate is at a constant 12 L/hr. Assume the reaction rate -s follows normal Michaelis-Menten kinetics (the product formation step is slow and rate limiting) where the substrate binds with the enzyme to form complex ES. Assume that there is no immobilization or inhibition effects present. a. So-1.5 mol/L and Vmax-4.50 mol/(hr L) and Km- 0.0300 mol/L b. S,-0.030 mol/L and Vmax = 0.10 mol/(hr*L) and Km = 0.095 mol/L c. So= 0.90 mol/L and Vmax 0.10 mol/(hr*L) and Km = 0.0750 mol/L lfitismotpossibletodetermine thereactor vol esforthedata given above, l tthe remai ingvariables that are needed to determine the reactor volumes.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

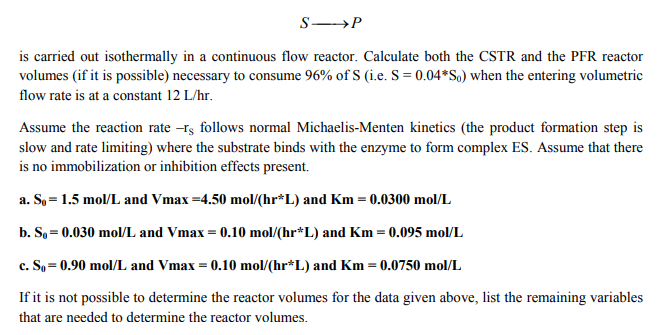

Transcribed Image Text:is carried out isothermally in a continuous flow reactor. Calculate both the CSTR and the PFR reactor

volumes (if it is possible) necessary to consurme 96% of S (ie. S = 0.04 *S) when the entering volumetric

flow rate is at a constant 12 L/hr.

Assume the reaction rate -s follows normal Michaelis-Menten kinetics (the product formation step is

slow and rate limiting) where the substrate binds with the enzyme to form complex ES. Assume that there

is no immobilization or inhibition effects present.

a. So-1.5 mol/L and Vmax-4.50 mol/(hr L) and Km- 0.0300 mol/L

b. S,-0.030 mol/L and Vmax = 0.10 mol/(hr*L) and Km = 0.095 mol/L

c. So= 0.90 mol/L and Vmax 0.10 mol/(hr*L) and Km = 0.0750 mol/L

lfitismotpossibletodetermine thereactor vol esforthedata given above, l tthe remai ingvariables

that are needed to determine the reactor volumes.

Expert Solution

Trending now

This is a popular solution!

Step by step

Solved in 10 steps with 9 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The