Jill's Job Shop buys two parts (Tegdiws and Widgets) for use in its production system from two different suppliers. The parts are needed throughout the entire 52-week year. Tegdiws are used at a relatively constant rate and are ordered whenever the remaining quantity drops to the reorder level. Widgets are ordered from a supplier who stops by every four weeks. Data for both products are as follows: ITEM Annual demand Holding cost (% of item cost) Setup or order cost Lead time Safety stock Item cost TEGDIW 11,000 10 % $110.00 Optimal reorder quantity Reorder point 4 weeks 65 units $15 a. What is the reorder quantity and reorder point for Tegdiws? Note: Round your answers to the nearest whole number. Answer is complete but not entirely correct. 550 x units 911✔ units WIDGET 8,000 20 % $10.00 4 week 7 units $8

Jill's Job Shop buys two parts (Tegdiws and Widgets) for use in its production system from two different suppliers. The parts are needed throughout the entire 52-week year. Tegdiws are used at a relatively constant rate and are ordered whenever the remaining quantity drops to the reorder level. Widgets are ordered from a supplier who stops by every four weeks. Data for both products are as follows: ITEM Annual demand Holding cost (% of item cost) Setup or order cost Lead time Safety stock Item cost TEGDIW 11,000 10 % $110.00 Optimal reorder quantity Reorder point 4 weeks 65 units $15 a. What is the reorder quantity and reorder point for Tegdiws? Note: Round your answers to the nearest whole number. Answer is complete but not entirely correct. 550 x units 911✔ units WIDGET 8,000 20 % $10.00 4 week 7 units $8

Purchasing and Supply Chain Management

6th Edition

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

ChapterC: Cases

Section: Chapter Questions

Problem 5.1SC: Scenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing...

Related questions

Question

100%

Operations Management CH 11

Please show work and explain. Thank you.

Question 7, Part A & B

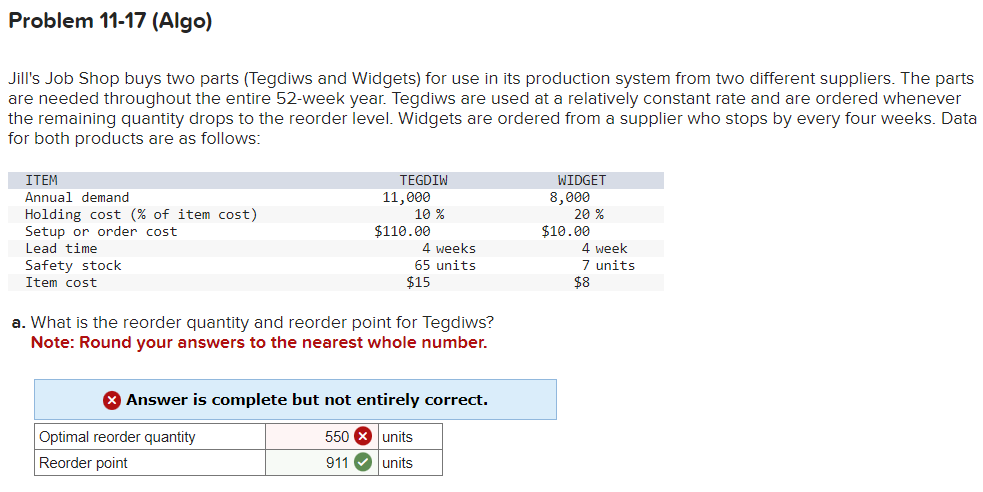

Transcribed Image Text:Problem 11-17 (Algo)

Jill's Job Shop buys two parts (Tegdiws and Widgets) for use in its production system from two different suppliers. The parts

are needed throughout the entire 52-week year. Tegdiws are used at a relatively constant rate and are ordered whenever

the remaining quantity drops to the reorder level. Widgets are ordered from a supplier who stops by every four weeks. Data

for both products are as follows:

ITEM

Annual demand

Holding cost (% of item cost)

Setup or order cost

Lead time

Safety stock

Item cost

TEGDIW

11,000

10 %

$110.00

Optimal reorder quantity

Reorder point

4 weeks

65 units

$15

a. What is the reorder quantity and reorder point for Tegdiws?

Note: Round your answers to the nearest whole number.

Answer is complete but not entirely correct.

550 x units

911✔✔ units

WIDGET

8,000

20 %

$10.00

4 week

7 units

$8

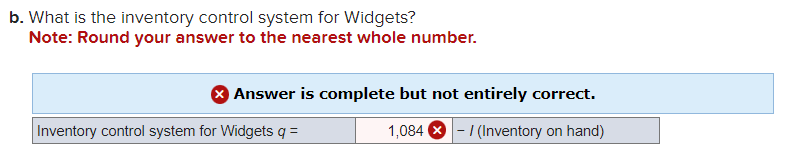

Transcribed Image Text:b. What is the inventory control system for Widgets?

Note: Round your answer to the nearest whole number.

> Answer is complete but not entirely correct.

1,084 - / (Inventory on hand)

Inventory control system for Widgets q =

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Recommended textbooks for you

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning