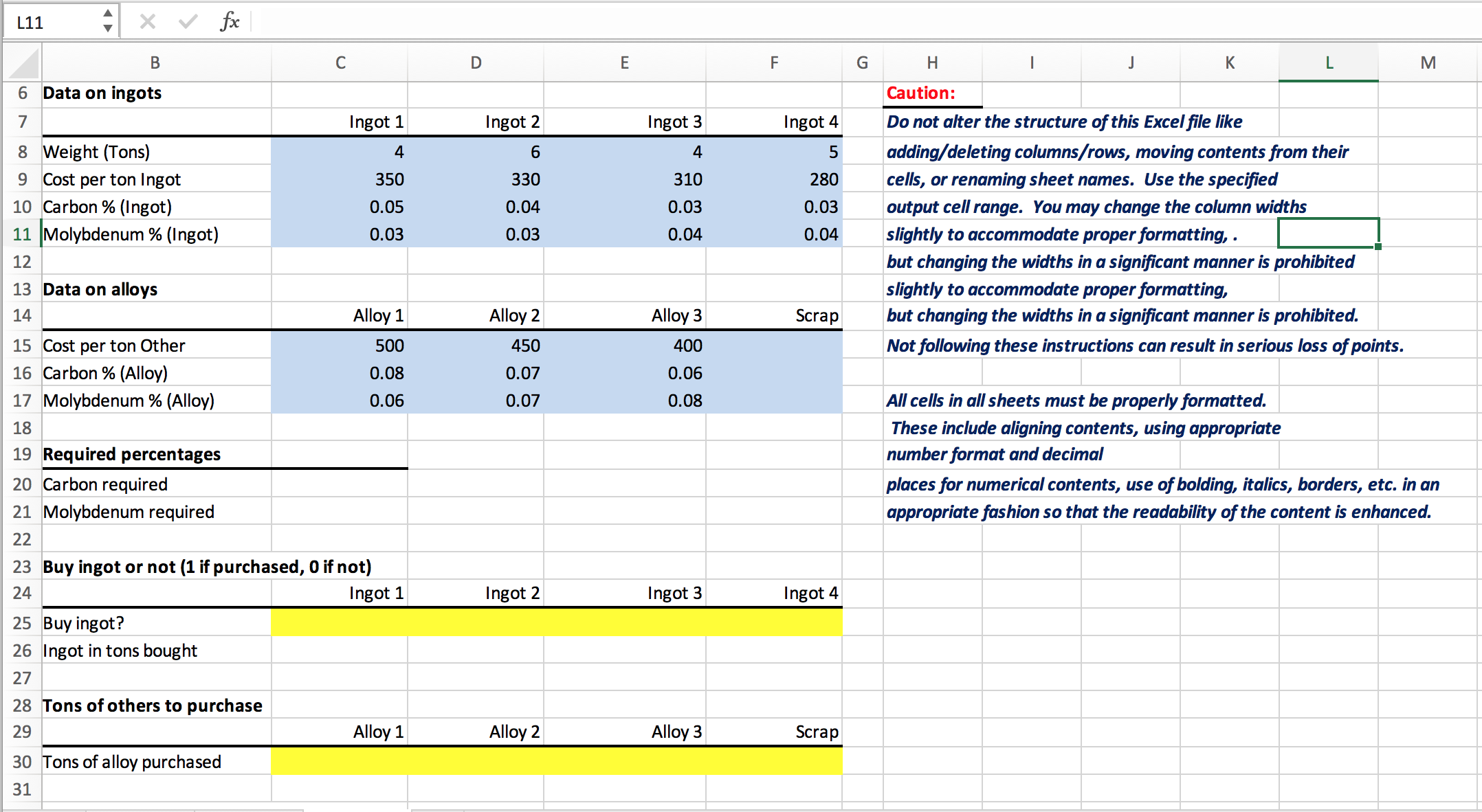

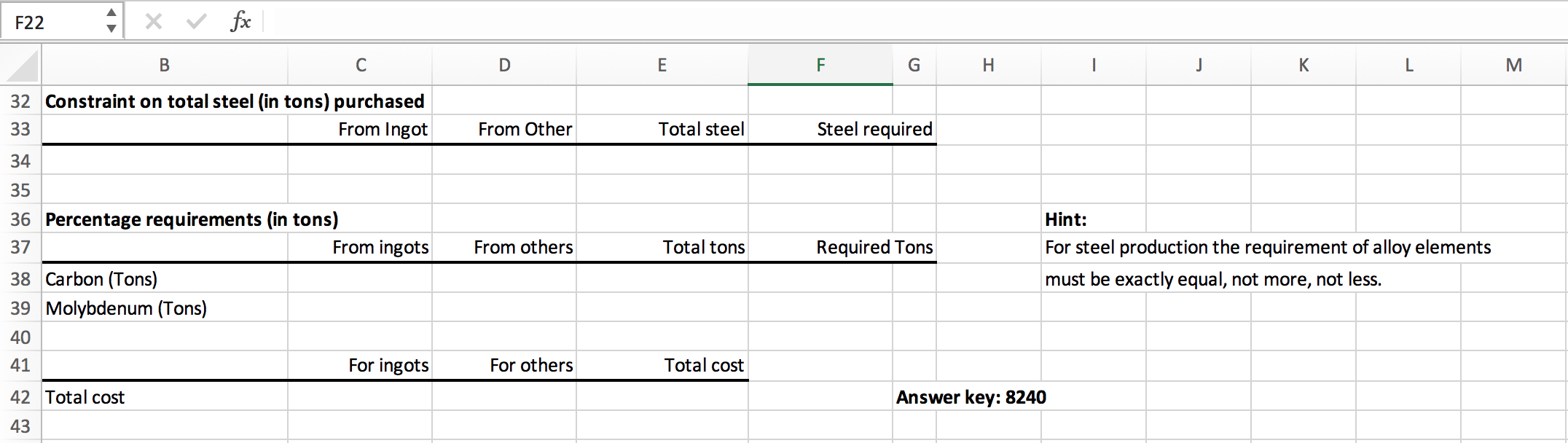

L11 D Н K 6 Data on ingots Caution: Ingot 1 Ingot 2 Ingot 3 Ingot 4 Do not alter the structure of this Excel file like 8 Weight (Tons) 4 4 adding/deleting columns/rows, moving contents from their 9 Cost per ton Ingot 350 330 310 280 cells, or renaming sheet names. Use the specified 10 Carbon % (Ingot) output cell range. You may change the column widths slightly to accommodate proper formatting, . 0.05 0.04 0.03 0.03 11 Molybdenum % (Ingot) 0.03 0.03 0.04 0.04 12 but changing the widths in a significant manner is prohibited 13 Data on alloys slightly to accommodate proper formatting, 14 Alloy 1 Alloy 2 Alloy 3 Scrap but changing the widths in a significant manner is prohibited. 15 Cost per ton Other 500 450 400 Not following these instructions can result in serious loss of points. 16 Carbon % (Alloy) 0.08 0.07 0.06 17 Molybdenum % (Alloy) 0.06 0.07 0.08 All cells in all sheets must be properly formatted. 18 These include aligning contents, using appropriate 19 Required percentages number format and decimal 20 Carbon required places for numerical contents, use of bolding, italics, borders, etc. in an 21 Molybdenum required appropriate fashion so that the readability of the content is enhanced. 22 23 Buy ingot or not (1 if purchased, O if not) 24 Ingot 1 Ingot 2 Ingot 3 Ingot 4 25 Buy ingot? 26 Ingot in tons bought 27 28 Tons of others to purchase 29 Alloy 1 Alloy 2 Alloy 3 Scrap 30 Tons of alloy purchased F22 G Н K 32 Constraint on total steel (in tons) purchased 33 From Ingot From Other Total steel Steel required 34 35 36 Percentage requirements (in tons) Hint: For steel production the requirement of alloy elements must be exactly equal, not more, not less. From ingots Total tons Required Tons 37 From others 38 Carbon (Tons) 39 Molybdenum (Tons) 40 41 For ingots For others Total cost 42 Total cost Answer key: 8240 43

68.

Based on Westerberg, Bjorklund, and Hultman (1977). Newcor’s steel mill has received an order for 25 tons of steel. The steel must be 5% carbon and 6% molybdenum by weight. The steel is manufactured by combining three types of metal: steel ingots, scrap steel, and alloys. Four individual steel ingots are available. At most, one of each can be purchased. The weight (in tons), cost per ton, and the carbon and molybdenum content of each ingot are given in the cells filled in light blue. Three types of alloys can be purchased. The cost per ton and chemical makeup of each alloy are given in the same file. Steel scrap can be purchased at a cost of $100 per ton. Steel scrap contains 3% carbon and 9% molybdenum. Determine how Newcor can minimize the cost of filling its order.

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 3 images