M4.17 Asteel shaft has a starting diameter= 15.00 mm. It is to be inserted into a hole in an expansion fit assembly operation. To be readily inserted, the shaft must be reduced in diameter by cooling Determine the temperature to which the shaft must be reduced from room temperature (20°C) in order to reduce its diameter to 14.98 mm. Use Table 4.1 from the book for reference. Round to the nearest 10th of a C Table 4.1 Volumetric properties in U.S. customary units for selected engineering materials Coclicient of Thermal Expansion, a Cx10F10 Melting Point, T Density, p g/em Material Metals Aluminum 2.70 (0.098) (13.3) 660 (1220) 24 Copper 8.97 (0.324) 17 1083 (1981) (94) Iron 7.87 (0.284) 12.1 (6.7) 1539 (2802) Lead 11.35 (0.410) 29 (621) (16.1) 327 Magnesium 1.74 (0.063) 26 (144) 650 (1202) Nickel 8.92 (0.322) 13.3 (7.4) (2651) 1455 Steel (0.284) 7.87 12 (6.7) a Tin 7.3 (0.264) 23 (12.7) 232 (449) Titanium 4.51 (0.163) 8.6 (4.7) 1668 (3034) Tungsten 19.30 (0.697) 4.0 (2.2) 3410 (6170) Zinc 7.15 (0.258) 40 (22.2) 420 (787) Ceramics and Silicon Glass 2.5 (0.090) 1.8-9.0 (1.0-5.0) Alumina 3.8 (0.137) 9.0 (5.0) 2072 (3762) Silica 2.66 (0.096) 0.55 (0.31) 1600 (2912) Silicon 2.33 (0.085) 2.6 (1.4) 1414 (2577) Polymers Phenol resins 1.3 (0.047) 60 (33) Nylon Polyethylene I.16 (0042) 100 (55) 260 (500) 0.92 (0.033) 180 (100) 115 (240) Polystyrene 1.05 (0.038) 70 (39) 240 (464) Polyvinylchloride 140 (0.051) 50 (28) 212 (414) Compiled from. 121.131. 141. 15). and other sources Melting tesmperature depends on composition Low-density polyethylene Chemically degrades at high temperanures because it is a thermosetting polymer, ocher polymers listed are thermoplastic

M4.17 Asteel shaft has a starting diameter= 15.00 mm. It is to be inserted into a hole in an expansion fit assembly operation. To be readily inserted, the shaft must be reduced in diameter by cooling Determine the temperature to which the shaft must be reduced from room temperature (20°C) in order to reduce its diameter to 14.98 mm. Use Table 4.1 from the book for reference. Round to the nearest 10th of a C Table 4.1 Volumetric properties in U.S. customary units for selected engineering materials Coclicient of Thermal Expansion, a Cx10F10 Melting Point, T Density, p g/em Material Metals Aluminum 2.70 (0.098) (13.3) 660 (1220) 24 Copper 8.97 (0.324) 17 1083 (1981) (94) Iron 7.87 (0.284) 12.1 (6.7) 1539 (2802) Lead 11.35 (0.410) 29 (621) (16.1) 327 Magnesium 1.74 (0.063) 26 (144) 650 (1202) Nickel 8.92 (0.322) 13.3 (7.4) (2651) 1455 Steel (0.284) 7.87 12 (6.7) a Tin 7.3 (0.264) 23 (12.7) 232 (449) Titanium 4.51 (0.163) 8.6 (4.7) 1668 (3034) Tungsten 19.30 (0.697) 4.0 (2.2) 3410 (6170) Zinc 7.15 (0.258) 40 (22.2) 420 (787) Ceramics and Silicon Glass 2.5 (0.090) 1.8-9.0 (1.0-5.0) Alumina 3.8 (0.137) 9.0 (5.0) 2072 (3762) Silica 2.66 (0.096) 0.55 (0.31) 1600 (2912) Silicon 2.33 (0.085) 2.6 (1.4) 1414 (2577) Polymers Phenol resins 1.3 (0.047) 60 (33) Nylon Polyethylene I.16 (0042) 100 (55) 260 (500) 0.92 (0.033) 180 (100) 115 (240) Polystyrene 1.05 (0.038) 70 (39) 240 (464) Polyvinylchloride 140 (0.051) 50 (28) 212 (414) Compiled from. 121.131. 141. 15). and other sources Melting tesmperature depends on composition Low-density polyethylene Chemically degrades at high temperanures because it is a thermosetting polymer, ocher polymers listed are thermoplastic

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter6: Forced Convection Over Exterior Surfaces

Section: Chapter Questions

Problem 6.10P

Related questions

Question

Transcribed Image Text:M4.17 Asteel shaft has a starting diameter= 15.00 mm. It is to be inserted into a hole in an expansion

fit assembly operation. To be readily inserted, the shaft must be reduced in diameter by cooling

Determine the temperature to which the shaft must be reduced from room temperature (20°C) in

order to reduce its diameter to 14.98 mm. Use Table 4.1 from the book for reference. Round to the

nearest 10th of a C

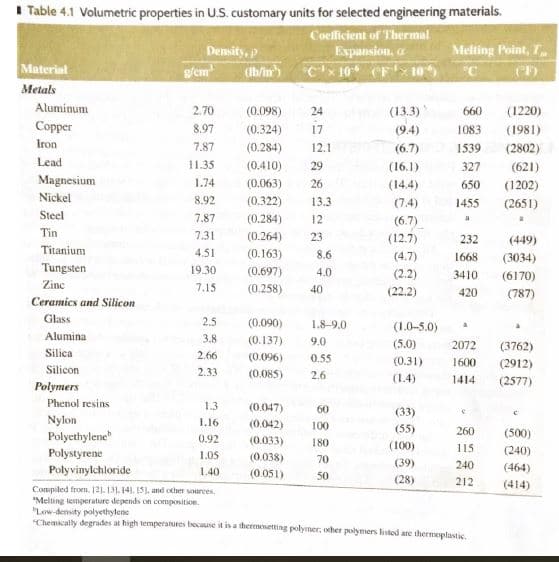

Transcribed Image Text:Table 4.1 Volumetric properties in U.S. customary units for selected engineering materials

Coclicient of Thermal

Expansion, a

Cx10F10

Melting Point, T

Density, p

g/em

Material

Metals

Aluminum

2.70

(0.098)

(13.3)

660

(1220)

24

Copper

8.97

(0.324)

17

1083

(1981)

(94)

Iron

7.87

(0.284)

12.1

(6.7)

1539

(2802)

Lead

11.35

(0.410)

29

(621)

(16.1)

327

Magnesium

1.74

(0.063)

26

(144)

650

(1202)

Nickel

8.92

(0.322)

13.3

(7.4)

(2651)

1455

Steel

(0.284)

7.87

12

(6.7)

a

Tin

7.3

(0.264)

23

(12.7)

232

(449)

Titanium

4.51

(0.163)

8.6

(4.7)

1668

(3034)

Tungsten

19.30

(0.697)

4.0

(2.2)

3410

(6170)

Zinc

7.15

(0.258)

40

(22.2)

420

(787)

Ceramics and Silicon

Glass

2.5

(0.090)

1.8-9.0

(1.0-5.0)

Alumina

3.8

(0.137)

9.0

(5.0)

2072

(3762)

Silica

2.66

(0.096)

0.55

(0.31)

1600

(2912)

Silicon

2.33

(0.085)

2.6

(1.4)

1414

(2577)

Polymers

Phenol resins

1.3

(0.047)

60

(33)

Nylon

Polyethylene

I.16

(0042)

100

(55)

260

(500)

0.92

(0.033)

180

(100)

115

(240)

Polystyrene

1.05

(0.038)

70

(39)

240

(464)

Polyvinylchloride

140

(0.051)

50

(28)

212

(414)

Compiled from. 121.131. 141. 15). and other sources

Melting tesmperature depends on composition

Low-density polyethylene

Chemically degrades at high temperanures because it is a thermosetting polymer, ocher polymers listed are thermoplastic

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 2 images

Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning