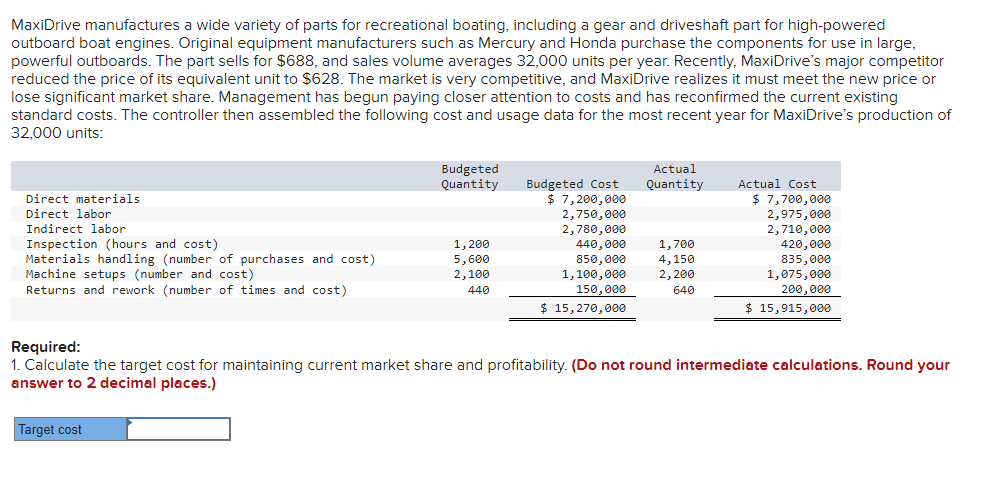

MaxiDrive manufactures a wide variety of parts for recreational boating, including a gear and driveshaft part for high-powered outboard boat engines. Original equipment manufacturers such as Mercury and Honda purchase the components for use in large, powerful outboards. The part sells for $688, and sales volume averages 32,000 units per year. Recently, MaxiDrive's major competitor reduced the price of its equivalent unit to $628. The market is very competitive, and MaxiDrive realizes it must meet the new price or lose significant market share. Management has begun paying closer attention to costs and has reconfirmed the current existing standard costs. The controller then assembled the following cost and usage data for the most recent year for MaxiDrive's production of 32,000 units: Direct materials Direct labor Indirect labor Inspection (hours and cost) Materials handling (number of purchases and cost) Machine setups (number and cost) Returns and rework (number of times and cost) Budgeted Quantity Target cost 1,200 5,600 2,100 440 Budgeted Cost $ 7,200,000 2,750,000 2,780,000 440,000 850,000 1,100,000 150,000 $ 15,270,000 Actual Quantity 1,700 4,150 2,200 640 Actual Cost $ 7,700,000 2,975,000 2,710,000 420,000 835,000 1,075,000 200,000 $ 15,915,000 Required: 1. Calculate the target cost for maintaining current market share and profitability. (Do not round intermediate calculations. Round your answer to 2 decimal places.)

MaxiDrive manufactures a wide variety of parts for recreational boating, including a gear and driveshaft part for high-powered outboard boat engines. Original equipment manufacturers such as Mercury and Honda purchase the components for use in large, powerful outboards. The part sells for $688, and sales volume averages 32,000 units per year. Recently, MaxiDrive's major competitor reduced the price of its equivalent unit to $628. The market is very competitive, and MaxiDrive realizes it must meet the new price or lose significant market share. Management has begun paying closer attention to costs and has reconfirmed the current existing standard costs. The controller then assembled the following cost and usage data for the most recent year for MaxiDrive's production of 32,000 units: Direct materials Direct labor Indirect labor Inspection (hours and cost) Materials handling (number of purchases and cost) Machine setups (number and cost) Returns and rework (number of times and cost) Budgeted Quantity Target cost 1,200 5,600 2,100 440 Budgeted Cost $ 7,200,000 2,750,000 2,780,000 440,000 850,000 1,100,000 150,000 $ 15,270,000 Actual Quantity 1,700 4,150 2,200 640 Actual Cost $ 7,700,000 2,975,000 2,710,000 420,000 835,000 1,075,000 200,000 $ 15,915,000 Required: 1. Calculate the target cost for maintaining current market share and profitability. (Do not round intermediate calculations. Round your answer to 2 decimal places.)

Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Don R. Hansen, Maryanne M. Mowen

Chapter16: Cost-volume-profit Analysis

Section: Chapter Questions

Problem 39P

Related questions

Question

Transcribed Image Text:MaxiDrive manufactures a wide variety of parts for recreational boating, including a gear and driveshaft part for high-powered

outboard boat engines. Original equipment manufacturers such as Mercury and Honda purchase the components for use in large,

powerful outboards. The part sells for $688, and sales volume averages 32,000 units per year. Recently, MaxiDrive's major competitor

reduced the price of its equivalent unit to $628. The market is very competitive, and MaxiDrive realizes it must meet the new price or

lose significant market share. Management has begun paying closer attention to costs and has reconfirmed the current existing

standard costs. The controller then assembled the following cost and usage data for the most recent year for MaxiDrive's production of

32,000 units:

Direct materials

Direct labor

Indirect labor

Inspection (hours and cost)

Materials handling (number of purchases and cost)

Machine setups (number and cost)

Returns and rework (number of times and cost)

Budgeted

Quantity

Target cost

1,200

5,600

2,100

440

Budgeted Cost

$ 7,200,000

2,750,000

2,780,000

440,000

850,000

1,100,000

150,000

$ 15,270,000

Actual

Quantity

1,700

4,150

2,200

640

Actual Cost

$ 7,700,000

2,975,000

2,710,000

420,000

835,000

1,075,000

200,000

$ 15,915,000

Required:

1. Calculate the target cost for maintaining current market share and profitability. (Do not round intermediate calculations. Round your

answer to 2 decimal places.)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning