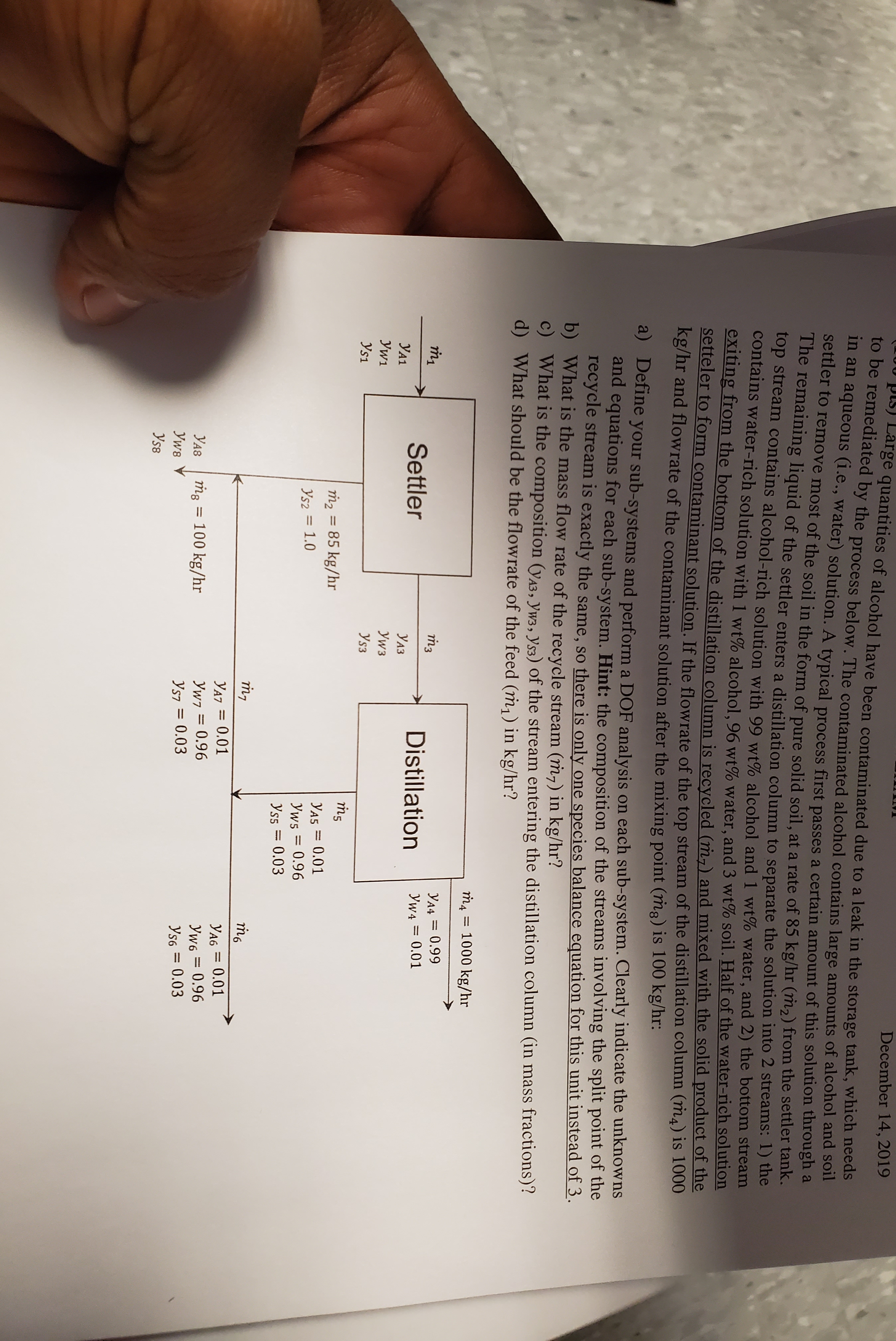

pis) Large quantities of alcohol have been contaminated due to a leak in the storage tank, which needs to be remediated by the process below. The contaminated alcohol contains large amounts of alcohol and ol in an aqueous (i.e., water) solution. A typical process first passes a certain amount of this solution through a settler to remove most of the soil in the form of pure solid soil, at a rate of 85 kg/hr (m2) from the settler tank. The remaining liquid of the settler enters a distillation column to separate the solution into 2 streams: 1) the top stream contains alcohol-rich solution with 99 wt% alcohol and 1 wt% water, and 2) the bottom stream contains water-rich solution with 1 wt% alcohol, 96 wt% water, and 3 wt% soil. Half of the water-rich solution eXiting from the bottom of the distillation column is recycled (m,) and mixed with the solid product of the setteler to form contaminant solution. If the flowrate of the top stream of the distillation column (m4) is 1000 kg/hr and flowrate of the contaminant solution after the mixing point (mg) is 100 kg/hr: December 14, 2019 a) Define your sub-systems and perform a DOF analysis on each sub-system. Clearly indicate the unknowns and equations for each sub-system. Hint: the composition of the streams involving the split point of the recycle stream is exactly the same, so there is only one species balance equation for this unit instead of 3. b) What is the mass flow rate of the recycle stream (m,) in kg/hr? 6. c) What is the composition (yA3, Yw3, Ys3) of the stream entering the distillation column (in mass fractions)? d) What should be the flowrate of the feed (m,) in kg/hr? та = 1000 kg/hr m3 Y44 = 0.99 Settler Distillation Yw4 = 0.01 УА1 УАЗ Уw1 Уw3 Ys1 Ys3 m2 = 85 kg/hr YA5 = 0.01 Yws = 0.96 Yss = 0.03 Ys2 = 1.0 %3D YA7 = 0.01 YA6 = 0.01 %3D Yw6 = 0.96 Ys6 = 0.03 УА8 ṁg = 100 kg/hr Yw7 = 0.96 %3D Уws Ys7 = 0.03 Ys8

pis) Large quantities of alcohol have been contaminated due to a leak in the storage tank, which needs to be remediated by the process below. The contaminated alcohol contains large amounts of alcohol and ol in an aqueous (i.e., water) solution. A typical process first passes a certain amount of this solution through a settler to remove most of the soil in the form of pure solid soil, at a rate of 85 kg/hr (m2) from the settler tank. The remaining liquid of the settler enters a distillation column to separate the solution into 2 streams: 1) the top stream contains alcohol-rich solution with 99 wt% alcohol and 1 wt% water, and 2) the bottom stream contains water-rich solution with 1 wt% alcohol, 96 wt% water, and 3 wt% soil. Half of the water-rich solution eXiting from the bottom of the distillation column is recycled (m,) and mixed with the solid product of the setteler to form contaminant solution. If the flowrate of the top stream of the distillation column (m4) is 1000 kg/hr and flowrate of the contaminant solution after the mixing point (mg) is 100 kg/hr: December 14, 2019 a) Define your sub-systems and perform a DOF analysis on each sub-system. Clearly indicate the unknowns and equations for each sub-system. Hint: the composition of the streams involving the split point of the recycle stream is exactly the same, so there is only one species balance equation for this unit instead of 3. b) What is the mass flow rate of the recycle stream (m,) in kg/hr? 6. c) What is the composition (yA3, Yw3, Ys3) of the stream entering the distillation column (in mass fractions)? d) What should be the flowrate of the feed (m,) in kg/hr? та = 1000 kg/hr m3 Y44 = 0.99 Settler Distillation Yw4 = 0.01 УА1 УАЗ Уw1 Уw3 Ys1 Ys3 m2 = 85 kg/hr YA5 = 0.01 Yws = 0.96 Yss = 0.03 Ys2 = 1.0 %3D YA7 = 0.01 YA6 = 0.01 %3D Yw6 = 0.96 Ys6 = 0.03 УА8 ṁg = 100 kg/hr Yw7 = 0.96 %3D Уws Ys7 = 0.03 Ys8

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

100%

Transcribed Image Text:pis) Large quantities of alcohol have been contaminated due to a leak in the storage tank, which needs

to be remediated by the process below. The contaminated alcohol contains large amounts of alcohol and ol

in an aqueous (i.e., water) solution. A typical process first passes a certain amount of this solution through a

settler to remove most of the soil in the form of pure solid soil, at a rate of 85 kg/hr (m2) from the settler tank.

The remaining liquid of the settler enters a distillation column to separate the solution into 2 streams: 1) the

top stream contains alcohol-rich solution with 99 wt% alcohol and 1 wt% water, and 2) the bottom stream

contains water-rich solution with 1 wt% alcohol, 96 wt% water, and 3 wt% soil. Half of the water-rich solution

eXiting from the bottom of the distillation column is recycled (m,) and mixed with the solid product of the

setteler to form contaminant solution. If the flowrate of the top stream of the distillation column (m4) is 1000

kg/hr and flowrate of the contaminant solution after the mixing point (mg) is 100 kg/hr:

December 14, 2019

a) Define your sub-systems and perform a DOF analysis on each sub-system. Clearly indicate the unknowns

and equations for each sub-system. Hint: the composition of the streams involving the split point of the

recycle stream is exactly the same, so there is only one species balance equation for this unit instead of 3.

b) What is the mass flow rate of the recycle stream (m,) in kg/hr?

6.

c) What is the composition (yA3, Yw3, Ys3) of the stream entering the distillation column (in mass fractions)?

d) What should be the flowrate of the feed (m,) in kg/hr?

та

= 1000 kg/hr

m3

Y44 = 0.99

Settler

Distillation

Yw4 = 0.01

УА1

УАЗ

Уw1

Уw3

Ys1

Ys3

m2 = 85 kg/hr

YA5 = 0.01

Yws = 0.96

Yss = 0.03

Ys2 = 1.0

%3D

YA7 = 0.01

YA6 = 0.01

%3D

Yw6 = 0.96

Ys6 = 0.03

УА8

ṁg = 100 kg/hr

Yw7 = 0.96

%3D

Уws

Ys7 = 0.03

Ys8

Expert Solution

Trending now

This is a popular solution!

Step by step

Solved in 9 steps with 9 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The