Please help me answer these questions. 1.1 A wire with 3 micron radius is made from 9 cm copper, 0.5 cm iron, and 11 cm copper all joined end to end (i.e., in series). Assume the joints are perfect and have no additional resistance. What is the total resistance of the wire? (extra info Fig 1)

Please help me answer these questions.

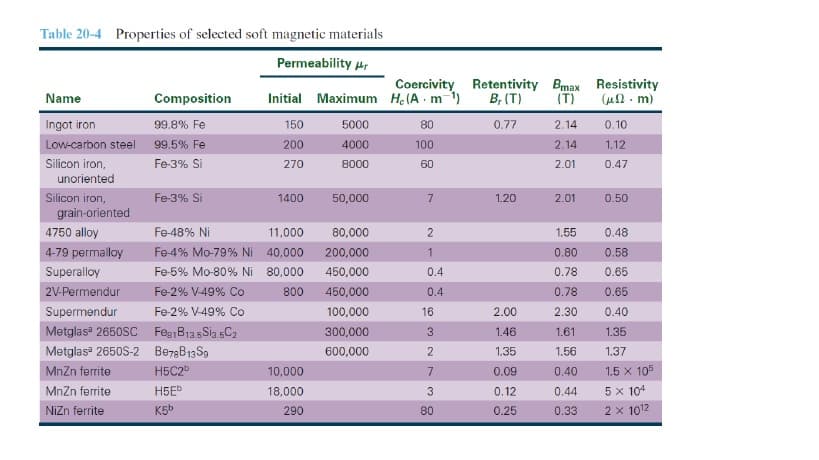

1.1 A wire with 3 micron radius is made from 9 cm copper, 0.5 cm iron, and 11 cm copper all joined end to end (i.e., in series). Assume the joints are perfect and have no additional resistance. What is the total resistance of the wire? (extra info Fig 1)

1.2 In a welding process, a current of 400 A flows through the arc when the voltage is 35 V. The length of the arc is 2.5mm, and the average diameter of the arc is 4.5mm. Calculate the current density in the arc, the electric field across the arc, and the electrical conductivity of the hot gases in the arc during welding.

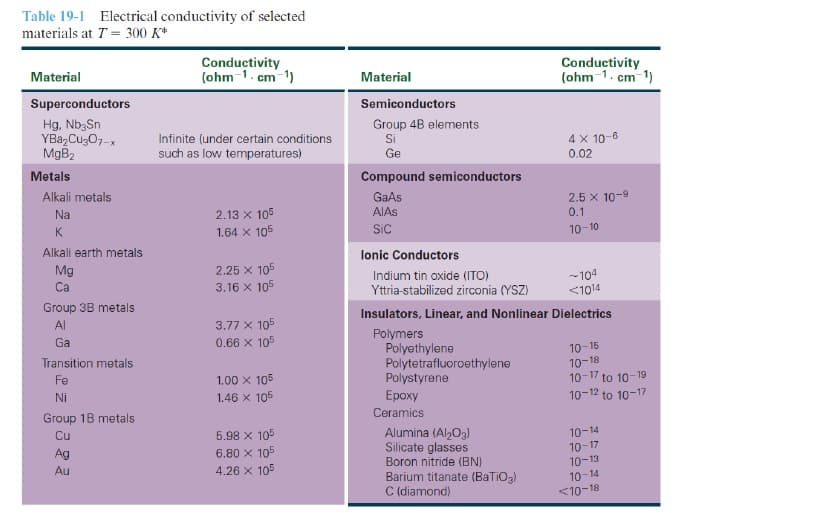

1.3 A 4-79 permalloy solenoid coil needs to produce a minimum inductance of 1.5 Wb/m2. If the maximum allowed current is 8mA, how many turns are required in a wire 132cm long? (extra info Fig 2)

Step by step

Solved in 2 steps with 1 images