Preparation of Isobornyl Acetate. Dissolve 4.1 g (0.030 mol) of camphene in 10 mL (10 g, 0.17 mol) of glacial acetic acid (CAUTION: Glacial acetic acid can cause severe burnsl Handle with carel) in a 50- mL Erlenmeyer flask. Add 1 mL of 6 M sulfuric acid (CAUTION: Sulfuric acetic acid can cause severe burnsl Handle with carel and heat the flask on a hot plate in the hood for 15 min at 90-95°C with frequent swirling (DO NOT stir with your thermometer). Add 20 mL of water (CAUTION: Ecotbermic reactionl), mix, and cool; then add 25 mL diethyl ether and mix. Transfer the mixture to a 125-mL separatory funnel, rinsing the flask with a little water. Separate the lower aqueous layer and wash the ether phase in the separatory funnel with water, then with 10% aqueous sodium carbonate (CAUTION: Evolution of CO, then with satd NaCl. Transfer the ether layer to a clean, preweighed 50-mL round-bottom flask and evaporate the ether. Obtain the yield of your crude isobornyl acetate. The crude product is suitable for conversion to isobor- neol without further purification. STOP HERE. Preparation of Isoborneol Into the a 50-mL round-bottom flask containing your crude isobornyl acetate, add 12 mL ethanol, 4 mL water, and 2.3 g potassium hydroxide pellets (CAUTION: Strong basel Very caustic) and two boiling chips. Heat the mixture under reflux for 1 hour (see Fig. 18; be sure to grease the joint between the flask and the reflux condenser with silicone grease). - H20 out - H20 in Ohan s Val C Figure 18. Reflux apparatus. Suh Inchode m Pour the reaction mixture slowly over until the isoborneol solidifies, then collect the product by suction filtration, and wash it with cold water. Allow the product to dry in your dessicator jar for one week. Obtain the yield of crude isoborneol. The crude isoborneol obtained is suitable for oxidation to camphor of crushed ice in a 100-mL beaker. Stir the mixture 30 Phonice suth an Preparation of Campbor. In a 250-mL Erlenmeyer flask, place your isoborneol and 50 mL diethyl ether (CAUTION: Flammable!). Slowly add 25 mL of stock chromic acid solution* by dropwise addition over 10 min. (CAUTION: Strong acidl Strong oxcidizing agent! Wear gloves! Avoid contact with skin, gyes, clothingl If this aocidizing agent comes in contact with the slein, wash the affected area thoroughly with soap and water, then rinse with sodium bicarbonate solution). Thoroughly mix the solution by swirling during the addition. Allow the reaction to proceed for one hour with frequent stirring *To prepare 1 L of stock chromic acid solution: Dissolve 160 g potassium dichromate (CAU- TION: Strong axidizing agentl) in 850 mL water. SLOWLY add, with swirling, 125 mL conc. sul- furic acid (CAUTION: Strong acid! Very corrosivel). Allow the solution to cool to room tempera- ture. Pour the reaction mixture into a separatory funnel. Separate the lower (aqueous) layer and dis- card into a container marked for chromium-containing wastes. Wash the remaining ether layer with 20 mL of 5% aqueous Na,CO3 (CAUTION: Evolution of CO), then dry it over anhydrous Na2SO4 Transfer the ether solution to a sublimation apparatus (glass Petri dish, see Fig. 19; read about Sublimation in FF&F, pp 111-114) and evaporate the ether. Sublime the crude camphor using a hot plate. Place the covered Petri dish with the crude camphor on a hot plate, place a beaker of water on top, and gently heat the crude camphor to effect sublimation. Collect the purified camphor crystals and determine the yield and the melting point.

Preparation of Isobornyl Acetate. Dissolve 4.1 g (0.030 mol) of camphene in 10 mL (10 g, 0.17 mol) of glacial acetic acid (CAUTION: Glacial acetic acid can cause severe burnsl Handle with carel) in a 50- mL Erlenmeyer flask. Add 1 mL of 6 M sulfuric acid (CAUTION: Sulfuric acetic acid can cause severe burnsl Handle with carel and heat the flask on a hot plate in the hood for 15 min at 90-95°C with frequent swirling (DO NOT stir with your thermometer). Add 20 mL of water (CAUTION: Ecotbermic reactionl), mix, and cool; then add 25 mL diethyl ether and mix. Transfer the mixture to a 125-mL separatory funnel, rinsing the flask with a little water. Separate the lower aqueous layer and wash the ether phase in the separatory funnel with water, then with 10% aqueous sodium carbonate (CAUTION: Evolution of CO, then with satd NaCl. Transfer the ether layer to a clean, preweighed 50-mL round-bottom flask and evaporate the ether. Obtain the yield of your crude isobornyl acetate. The crude product is suitable for conversion to isobor- neol without further purification. STOP HERE. Preparation of Isoborneol Into the a 50-mL round-bottom flask containing your crude isobornyl acetate, add 12 mL ethanol, 4 mL water, and 2.3 g potassium hydroxide pellets (CAUTION: Strong basel Very caustic) and two boiling chips. Heat the mixture under reflux for 1 hour (see Fig. 18; be sure to grease the joint between the flask and the reflux condenser with silicone grease). - H20 out - H20 in Ohan s Val C Figure 18. Reflux apparatus. Suh Inchode m Pour the reaction mixture slowly over until the isoborneol solidifies, then collect the product by suction filtration, and wash it with cold water. Allow the product to dry in your dessicator jar for one week. Obtain the yield of crude isoborneol. The crude isoborneol obtained is suitable for oxidation to camphor of crushed ice in a 100-mL beaker. Stir the mixture 30 Phonice suth an Preparation of Campbor. In a 250-mL Erlenmeyer flask, place your isoborneol and 50 mL diethyl ether (CAUTION: Flammable!). Slowly add 25 mL of stock chromic acid solution* by dropwise addition over 10 min. (CAUTION: Strong acidl Strong oxcidizing agent! Wear gloves! Avoid contact with skin, gyes, clothingl If this aocidizing agent comes in contact with the slein, wash the affected area thoroughly with soap and water, then rinse with sodium bicarbonate solution). Thoroughly mix the solution by swirling during the addition. Allow the reaction to proceed for one hour with frequent stirring *To prepare 1 L of stock chromic acid solution: Dissolve 160 g potassium dichromate (CAU- TION: Strong axidizing agentl) in 850 mL water. SLOWLY add, with swirling, 125 mL conc. sul- furic acid (CAUTION: Strong acid! Very corrosivel). Allow the solution to cool to room tempera- ture. Pour the reaction mixture into a separatory funnel. Separate the lower (aqueous) layer and dis- card into a container marked for chromium-containing wastes. Wash the remaining ether layer with 20 mL of 5% aqueous Na,CO3 (CAUTION: Evolution of CO), then dry it over anhydrous Na2SO4 Transfer the ether solution to a sublimation apparatus (glass Petri dish, see Fig. 19; read about Sublimation in FF&F, pp 111-114) and evaporate the ether. Sublime the crude camphor using a hot plate. Place the covered Petri dish with the crude camphor on a hot plate, place a beaker of water on top, and gently heat the crude camphor to effect sublimation. Collect the purified camphor crystals and determine the yield and the melting point.

Organic Chemistry: A Guided Inquiry

2nd Edition

ISBN:9780618974122

Author:Andrei Straumanis

Publisher:Andrei Straumanis

Chapter27: Amines

Section: Chapter Questions

Problem 9E

Related questions

Question

Calculate the theoretical yields of:

Isobornyl acetate

Isoborneol

Camphor

Transcribed Image Text:Preparation of Isobornyl Acetate. Dissolve 4.1 g (0.030 mol) of camphene in 10 mL (10 g, 0.17 mol)

of glacial acetic acid (CAUTION: Glacial acetic acid can cause severe burnsl Handle with carel) in a 50-

mL Erlenmeyer

flask. Add 1 mL of 6 M sulfuric acid (CAUTION: Sulfuric acetic acid can cause severe

burnsl Handle with carel and heat the flask on a hot plate in the hood for 15 min at 90-95°C with

frequent swirling (DO NOT stir with your thermometer). Add 20 mL of water (CAUTION:

Ecotbermic reactionl), mix, and cool; then add 25 mL diethyl ether and mix.

Transfer the mixture to a 125-mL separatory funnel, rinsing the flask with a little water. Separate

the lower aqueous layer and wash the ether phase in the separatory funnel with water, then with

10% aqueous sodium carbonate (CAUTION: Evolution of CO, then with satd NaCl. Transfer

the ether layer to a clean, preweighed 50-mL round-bottom flask and evaporate the ether. Obtain

the yield of your crude isobornyl acetate. The crude product is suitable for conversion to isobor-

neol without further purification. STOP HERE.

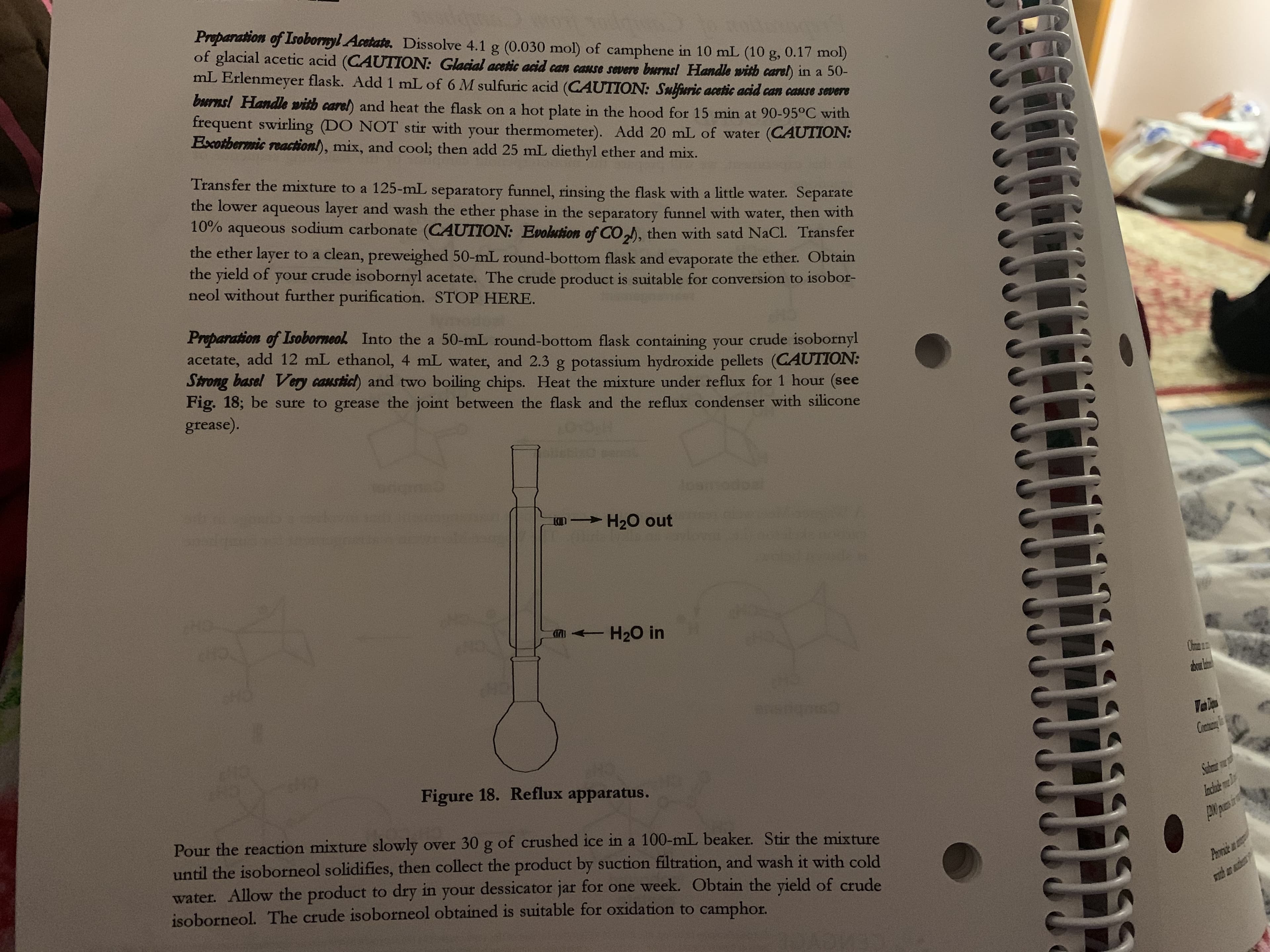

Preparation of Isoborneol Into the a 50-mL round-bottom flask containing your crude isobornyl

acetate, add 12 mL ethanol, 4 mL water, and 2.3 g potassium hydroxide pellets (CAUTION:

Strong basel Very caustic) and two boiling chips. Heat the mixture under reflux for 1 hour (see

Fig. 18; be sure to grease the joint between the flask and the reflux condenser with silicone

grease).

- H20 out

- H20 in

Ohan

s

Val

C

Figure 18. Reflux apparatus.

Suh

Inchode m

Pour the reaction mixture slowly over

until the isoborneol solidifies, then collect the product by suction filtration, and wash it with cold

water. Allow the product to dry in your dessicator jar for one week. Obtain the yield of crude

isoborneol. The crude isoborneol obtained is suitable for oxidation to camphor

of crushed ice in a 100-mL beaker. Stir the mixture

30

Phonice

suth an

Transcribed Image Text:Preparation of Campbor. In a 250-mL Erlenmeyer flask, place your isoborneol and 50 mL diethyl

ether (CAUTION: Flammable!). Slowly add 25 mL of stock chromic acid solution* by dropwise

addition over 10 min. (CAUTION: Strong acidl Strong oxcidizing agent! Wear gloves! Avoid contact with

skin, gyes, clothingl If this aocidizing agent comes in contact with the slein, wash the affected area thoroughly with

soap and water, then rinse with sodium bicarbonate solution). Thoroughly mix the solution by swirling

during the addition. Allow the reaction to proceed for one hour with frequent stirring

*To prepare 1 L of stock chromic acid solution: Dissolve 160 g potassium dichromate (CAU-

TION: Strong axidizing agentl) in 850 mL water. SLOWLY add, with swirling, 125 mL conc. sul-

furic acid (CAUTION: Strong acid! Very corrosivel). Allow the solution to cool to room tempera-

ture.

Pour the reaction mixture into a separatory funnel. Separate the lower (aqueous) layer and dis-

card into a container marked for chromium-containing wastes. Wash the remaining ether layer

with 20 mL of 5% aqueous Na,CO3 (CAUTION: Evolution of CO), then dry it over anhydrous

Na2SO4

Transfer the ether solution to a sublimation apparatus (glass Petri dish, see Fig. 19; read about

Sublimation in FF&F, pp 111-114) and evaporate the ether. Sublime the crude camphor using

a hot plate. Place the covered Petri dish with the crude camphor on a hot plate, place a beaker

of water on top, and gently heat the crude camphor to effect sublimation. Collect the purified

camphor crystals and determine the yield and the melting point.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemistry and related others by exploring similar questions and additional content below.Recommended textbooks for you

Organic Chemistry: A Guided Inquiry

Chemistry

ISBN:

9780618974122

Author:

Andrei Straumanis

Publisher:

Cengage Learning

Macroscale and Microscale Organic Experiments

Chemistry

ISBN:

9781305577190

Author:

Kenneth L. Williamson, Katherine M. Masters

Publisher:

Brooks Cole

Organic Chemistry: A Guided Inquiry

Chemistry

ISBN:

9780618974122

Author:

Andrei Straumanis

Publisher:

Cengage Learning

Macroscale and Microscale Organic Experiments

Chemistry

ISBN:

9781305577190

Author:

Kenneth L. Williamson, Katherine M. Masters

Publisher:

Brooks Cole