Print Reading for Industry 192 Class Date Name Industry Print Exercise 9-1 Refer to the print PR 9-1 and answer the questions below. 1. How many angular dimensions are shown on this print? 2. How many reference dimensions are shown on this print? 3. Did the creator of this print follow the cylinder rule for the overall diameter? 4. Does this print use the aligned system or the unidirectional system? 5. How many local notes with leader lines are there on this print? 6. Counting reference dimensions, how many diameters are specified? Review questions based previous units: 7. What paper size is the original version of this print? 8. What is the material for this part? 9. What is the name of this part? 10. What is the part number of this print? 11. To what scale is the part drawn on the original drawing? 12. If the far-left circular view is called the left side view, what names would be given to the other three views? 13. How many "through holes" does this object have? 14. Counting all surfaces of the object, how many are "flat" planar surfaces? 15. Does this drawing feature any section views? 6 ENG2 12C ALL REVISI ONS TO THIS DRAWING MUST BE MADE ON THE CAD SYSTEM NO TES: 1. ALL UND I MENS I ONED CORNERS TO BE .010 MAX. 2. BURRS TO BE 002 MAX. 3-D VIEWS SHOWN FOR REFERENCE ONLY NOT TO SCALE 249/ 250 DIA. .002 A .09L .025 X 45 CHAMFER . 193 : t.020 .020X45 CHAMFER CHANGED GEO. TOL MCM/DAD 03 ON 060 DIM. 5-30-00FCN 332896 SJN 5/30 KLR/TEK ORIGINAL A 4-30-98 ECN 324045 DWS 4/30 SSUE APP/DATE .216 DIA REF 093t . 00 1 - A- DIA DESCRIPTION REVISIONS 170t . 010 219 GRAYHILL, INC. 561 HILLGROVE AVE LA GRANGE. IL PHONE (708) 354-1040 60525 .193 DIM. UNLESS OTHERWISE SPECIFIED TOLERANCES AND DIMENS IONS ARE IN INCHES .915 REF . - LINEAR O04 DIAMETERS ANGUL AR 1 0 LIMITS APPLY BEFORE FINI SHING DO NOT SCALE THIS PRINT 003 .720 .250+ .005 CRITICAL CHARACTER I STIC FLAGS PER GRAYHILL SPEC.SOP2338 CRITICAL CHARACTERISTIC FLAG Cpk REQUIRED S.P.C. FLAG (CONTROL CHART REQ'D ON FEATURE SPECIFIED) DATE - APPROVED HSINI TEK .055 4-30 MATERIAL ALUMINUM CHECKED KLR DATE 4-30 195 NAME DRAWN DATE SHAFT. .250 DIA. 81073 SMG 4-30 CADAM DRAWING 621715 B 001 CAGE NO DWG. NO ISSUE 6217 15 3ZIS SCALE 4 1 SHEET OF 1

Print Reading for Industry 192 Class Date Name Industry Print Exercise 9-1 Refer to the print PR 9-1 and answer the questions below. 1. How many angular dimensions are shown on this print? 2. How many reference dimensions are shown on this print? 3. Did the creator of this print follow the cylinder rule for the overall diameter? 4. Does this print use the aligned system or the unidirectional system? 5. How many local notes with leader lines are there on this print? 6. Counting reference dimensions, how many diameters are specified? Review questions based previous units: 7. What paper size is the original version of this print? 8. What is the material for this part? 9. What is the name of this part? 10. What is the part number of this print? 11. To what scale is the part drawn on the original drawing? 12. If the far-left circular view is called the left side view, what names would be given to the other three views? 13. How many "through holes" does this object have? 14. Counting all surfaces of the object, how many are "flat" planar surfaces? 15. Does this drawing feature any section views? 6 ENG2 12C ALL REVISI ONS TO THIS DRAWING MUST BE MADE ON THE CAD SYSTEM NO TES: 1. ALL UND I MENS I ONED CORNERS TO BE .010 MAX. 2. BURRS TO BE 002 MAX. 3-D VIEWS SHOWN FOR REFERENCE ONLY NOT TO SCALE 249/ 250 DIA. .002 A .09L .025 X 45 CHAMFER . 193 : t.020 .020X45 CHAMFER CHANGED GEO. TOL MCM/DAD 03 ON 060 DIM. 5-30-00FCN 332896 SJN 5/30 KLR/TEK ORIGINAL A 4-30-98 ECN 324045 DWS 4/30 SSUE APP/DATE .216 DIA REF 093t . 00 1 - A- DIA DESCRIPTION REVISIONS 170t . 010 219 GRAYHILL, INC. 561 HILLGROVE AVE LA GRANGE. IL PHONE (708) 354-1040 60525 .193 DIM. UNLESS OTHERWISE SPECIFIED TOLERANCES AND DIMENS IONS ARE IN INCHES .915 REF . - LINEAR O04 DIAMETERS ANGUL AR 1 0 LIMITS APPLY BEFORE FINI SHING DO NOT SCALE THIS PRINT 003 .720 .250+ .005 CRITICAL CHARACTER I STIC FLAGS PER GRAYHILL SPEC.SOP2338 CRITICAL CHARACTERISTIC FLAG Cpk REQUIRED S.P.C. FLAG (CONTROL CHART REQ'D ON FEATURE SPECIFIED) DATE - APPROVED HSINI TEK .055 4-30 MATERIAL ALUMINUM CHECKED KLR DATE 4-30 195 NAME DRAWN DATE SHAFT. .250 DIA. 81073 SMG 4-30 CADAM DRAWING 621715 B 001 CAGE NO DWG. NO ISSUE 6217 15 3ZIS SCALE 4 1 SHEET OF 1

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

100%

I need help answering this.

Transcribed Image Text:Print Reading for Industry

192

Class

Date

Name

Industry Print Exercise 9-1

Refer to the print PR 9-1 and answer the questions below.

1. How many angular dimensions are shown on this print?

2. How many reference dimensions are shown on this print?

3. Did the creator of this print follow the cylinder rule for the overall diameter?

4. Does this print

use the aligned system or the unidirectional system?

5. How many local notes with leader lines are there on this print?

6. Counting reference dimensions, how many diameters are

specified?

Review questions based

previous units:

7. What paper size is the original version of this print?

8. What is the material for this part?

9. What is the name of this part?

10. What is the part number of this print?

11. To what scale is the part drawn on the original drawing?

12. If the far-left circular view is called the left side view, what names would be given to the other three

views?

13. How many "through holes" does this object have?

14. Counting all surfaces of the object, how many are "flat" planar surfaces?

15. Does this drawing feature any section views?

6

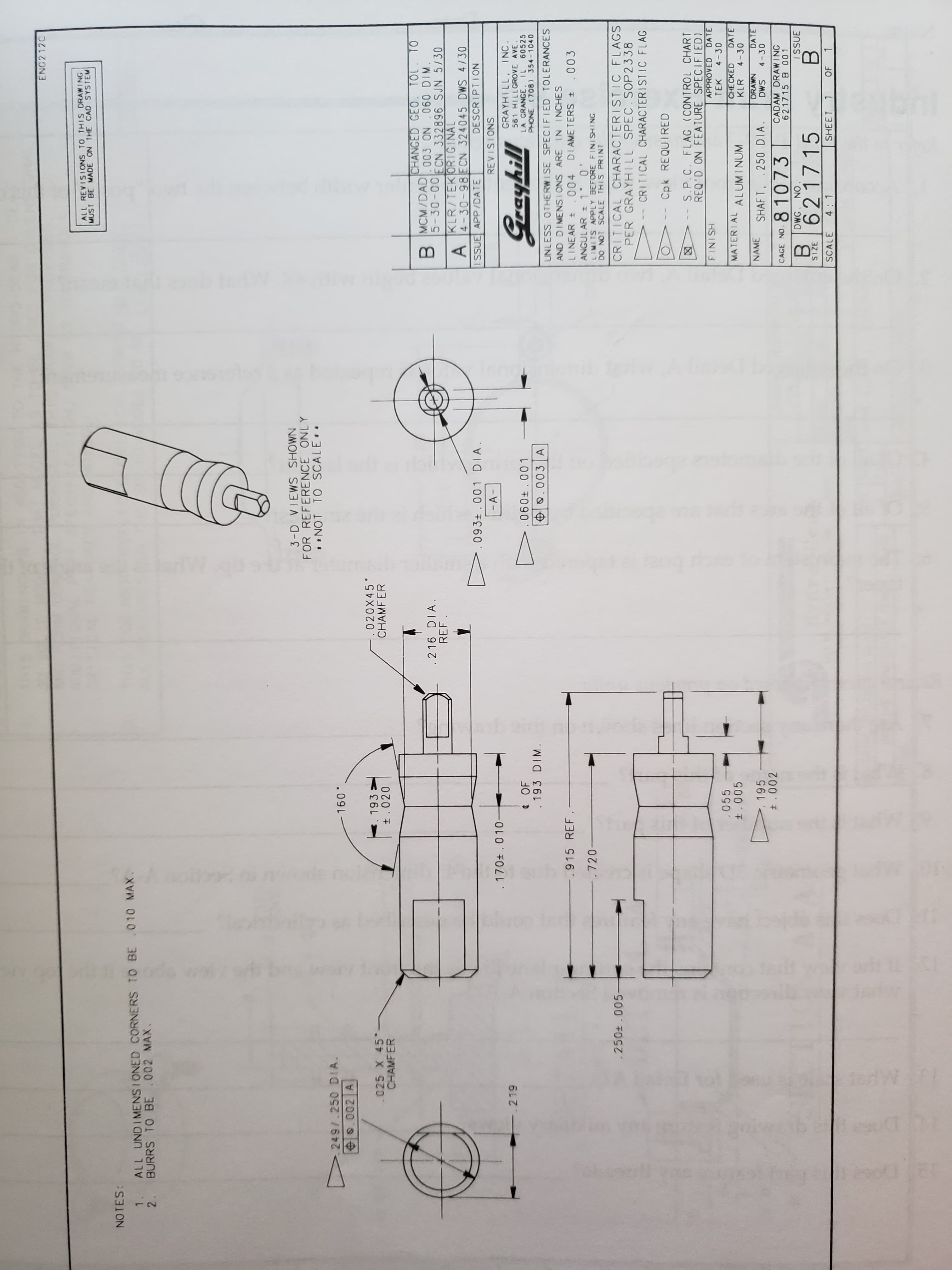

Transcribed Image Text:ENG2 12C

ALL REVISI ONS TO THIS DRAWING

MUST BE MADE ON THE CAD SYSTEM

NO TES:

1. ALL UND I MENS I ONED CORNERS TO BE .010 MAX.

2. BURRS TO BE 002 MAX.

3-D VIEWS SHOWN

FOR REFERENCE ONLY

NOT TO SCALE

249/ 250 DIA.

.002 A

.09L

.025 X 45

CHAMFER

. 193 :

t.020

.020X45

CHAMFER

CHANGED GEO. TOL

MCM/DAD 03 ON 060 DIM.

5-30-00FCN 332896 SJN 5/30

KLR/TEK ORIGINAL

A 4-30-98 ECN 324045 DWS 4/30

SSUE APP/DATE

.216 DIA

REF

093t . 00 1

- A-

DIA

DESCRIPTION

REVISIONS

170t . 010

219

GRAYHILL, INC.

561 HILLGROVE AVE

LA GRANGE. IL

PHONE (708) 354-1040

60525

.193 DIM.

UNLESS OTHERWISE SPECIFIED TOLERANCES

AND DIMENS IONS ARE IN INCHES

.915 REF . -

LINEAR O04 DIAMETERS

ANGUL AR 1 0

LIMITS APPLY BEFORE FINI SHING

DO NOT SCALE THIS PRINT

003

.720

.250+ .005

CRITICAL CHARACTER I STIC FLAGS

PER GRAYHILL SPEC.SOP2338

CRITICAL CHARACTERISTIC FLAG

Cpk REQUIRED

S.P.C. FLAG (CONTROL CHART

REQ'D ON FEATURE SPECIFIED)

DATE

-

APPROVED

HSINI

TEK

.055

4-30

MATERIAL ALUMINUM

CHECKED

KLR

DATE

4-30

195

NAME

DRAWN

DATE

SHAFT. .250 DIA.

81073

SMG

4-30

CADAM DRAWING

621715 B 001

CAGE NO

DWG. NO

ISSUE

6217 15

3ZIS

SCALE

4 1

SHEET

OF 1

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY