Print Reading for Industry 282 Class Name Date Industry Print Exercise 13-1 Refer to the print PR 13-1 and answer the questions below. 1. Are the datums identified following the current standard or an older standard? 2. Before datum A can be used as a datum, what qualification must it meet? 3. What feature is used to establish datum B? 4. Why do the coordinate location dimensions have boxes around them? 5. Do any of the feature control frames specify a bonus tolerance? 6. The depth (front-to-back) of the part has a tolerance specified by the title block as .02" (t.01"). Nevertheless, the front surface must still be parallel to the back by what amount? 7. What is the MMC of datum feature B, which has a title block tolerance specification of .010" (t.005")? Review questions based on previous units: 8. What is the part number of this print? 9. How many threaded holes are there on this part? 10. What is the radius of the four corners of this part? 11. What type of metal should be used for this part? 12. What is the size tolerance on the four largest counterbore diameters? 13. What is the overall height, width, and depth of this part? H W 14. What type of section view is the right side view? 15. What type of representation is used to show the threads in the section view? Geometric Dimensioning and Tolerancing 283 898 2 908 (000 893 386 898 2 Print supplied by MASCO Corporatio PR 13-1. Cylinder Union Lower Support. 800 6.61 O.010 -A- 3.31 1.25 DRILL THRU & C'BORE FOR 3/8-16 S.H.C.S. (FROM OPPOSITE SIDE) 4 PLACES DRILL & REAM THRU FOR 1/4 DIA DOWEL S.F. 4 PLACES .78 .014 M A .002 A B .25 L.. 2.921 2.342 96 2 3.34 1.585 4X 1.031 800 4.47 .171 ( 000 ) .454 .758 4X 1.5007/1.501 o .002 A 4X R.44 - 5/8-18 TAP 4 PLACES .562 THRU Ø.010 A B 0050 -B- 800 SECTION A-A 1 REQD. DO NOT SCALE ORAWING THIS DRAVING AND THE INFORMAYION CONTAINEDTHEREON ARE THE FROPERTY OTHERS AND MAY 8SED ONLY POR TE FURPOSE OF ENABL INO THE PARTY TO WHOM IT HAS BEEN LOANED TO QUOTE ON OR PILL AN OR0ER FOR MASCO UNLESS OTHERWISE SPECIFIED LAYOUT NAME ORAFT MASCO A CORPORATION ANGUL AR DIM- +/-.05 2-PLACE DEC. -01 8-PLACE DEC. -.005 SHARP EDGES A .03 VIEWS DISP. DATE ISSUED NAME: DATE: TITLE 9200-/+ 30 d- MATERIAL: MASTECH CONTRL DIVISION LOWER SUPPORT CYLINDER UNION ORAWN A ADRIANSON 01/31/ 6061-T6 ALUMINUM DESTROY PREVIOUS PRINTS 217C017 CHECK REV DATE CHANGE: CHKD FINISH SCALE FULL APPR

Print Reading for Industry 282 Class Name Date Industry Print Exercise 13-1 Refer to the print PR 13-1 and answer the questions below. 1. Are the datums identified following the current standard or an older standard? 2. Before datum A can be used as a datum, what qualification must it meet? 3. What feature is used to establish datum B? 4. Why do the coordinate location dimensions have boxes around them? 5. Do any of the feature control frames specify a bonus tolerance? 6. The depth (front-to-back) of the part has a tolerance specified by the title block as .02" (t.01"). Nevertheless, the front surface must still be parallel to the back by what amount? 7. What is the MMC of datum feature B, which has a title block tolerance specification of .010" (t.005")? Review questions based on previous units: 8. What is the part number of this print? 9. How many threaded holes are there on this part? 10. What is the radius of the four corners of this part? 11. What type of metal should be used for this part? 12. What is the size tolerance on the four largest counterbore diameters? 13. What is the overall height, width, and depth of this part? H W 14. What type of section view is the right side view? 15. What type of representation is used to show the threads in the section view? Geometric Dimensioning and Tolerancing 283 898 2 908 (000 893 386 898 2 Print supplied by MASCO Corporatio PR 13-1. Cylinder Union Lower Support. 800 6.61 O.010 -A- 3.31 1.25 DRILL THRU & C'BORE FOR 3/8-16 S.H.C.S. (FROM OPPOSITE SIDE) 4 PLACES DRILL & REAM THRU FOR 1/4 DIA DOWEL S.F. 4 PLACES .78 .014 M A .002 A B .25 L.. 2.921 2.342 96 2 3.34 1.585 4X 1.031 800 4.47 .171 ( 000 ) .454 .758 4X 1.5007/1.501 o .002 A 4X R.44 - 5/8-18 TAP 4 PLACES .562 THRU Ø.010 A B 0050 -B- 800 SECTION A-A 1 REQD. DO NOT SCALE ORAWING THIS DRAVING AND THE INFORMAYION CONTAINEDTHEREON ARE THE FROPERTY OTHERS AND MAY 8SED ONLY POR TE FURPOSE OF ENABL INO THE PARTY TO WHOM IT HAS BEEN LOANED TO QUOTE ON OR PILL AN OR0ER FOR MASCO UNLESS OTHERWISE SPECIFIED LAYOUT NAME ORAFT MASCO A CORPORATION ANGUL AR DIM- +/-.05 2-PLACE DEC. -01 8-PLACE DEC. -.005 SHARP EDGES A .03 VIEWS DISP. DATE ISSUED NAME: DATE: TITLE 9200-/+ 30 d- MATERIAL: MASTECH CONTRL DIVISION LOWER SUPPORT CYLINDER UNION ORAWN A ADRIANSON 01/31/ 6061-T6 ALUMINUM DESTROY PREVIOUS PRINTS 217C017 CHECK REV DATE CHANGE: CHKD FINISH SCALE FULL APPR

International Edition---engineering Mechanics: Statics, 4th Edition

4th Edition

ISBN:9781305501607

Author:Andrew Pytel And Jaan Kiusalaas

Publisher:Andrew Pytel And Jaan Kiusalaas

Chapter1: Introduction To Statics

Section: Chapter Questions

Problem 1.12P: A differential equation encountered in the vibration of beams is d4ydx4=2D where x = distance...

Related questions

Question

I need help answering problems 13, 14, and 15 pertaining to the print provided.

Transcribed Image Text:Print Reading for Industry

282

Class

Name

Date

Industry Print Exercise 13-1

Refer to the print PR 13-1 and answer the questions below.

1. Are the datums identified following the current standard or an older standard?

2. Before datum A can be used as a datum, what qualification must it meet?

3. What feature is used to establish datum B?

4. Why do the coordinate location dimensions have boxes around them?

5. Do any of the feature control frames specify a bonus tolerance?

6. The depth (front-to-back) of the part has a tolerance specified by the title block as .02" (t.01").

Nevertheless, the front surface must still be parallel to the back by what amount?

7. What is the MMC of datum feature B, which has a title block tolerance specification of .010" (t.005")?

Review questions based on

previous units:

8. What is the part number of this print?

9. How many threaded holes are there on this part?

10. What is the radius of the four corners of this part?

11. What type of metal should be used for this part?

12. What is the size tolerance on the four largest counterbore diameters?

13. What is the overall height, width, and depth of this part? H

W

14. What type of section view is the right side view?

15. What type of representation is used to show the threads in the section view?

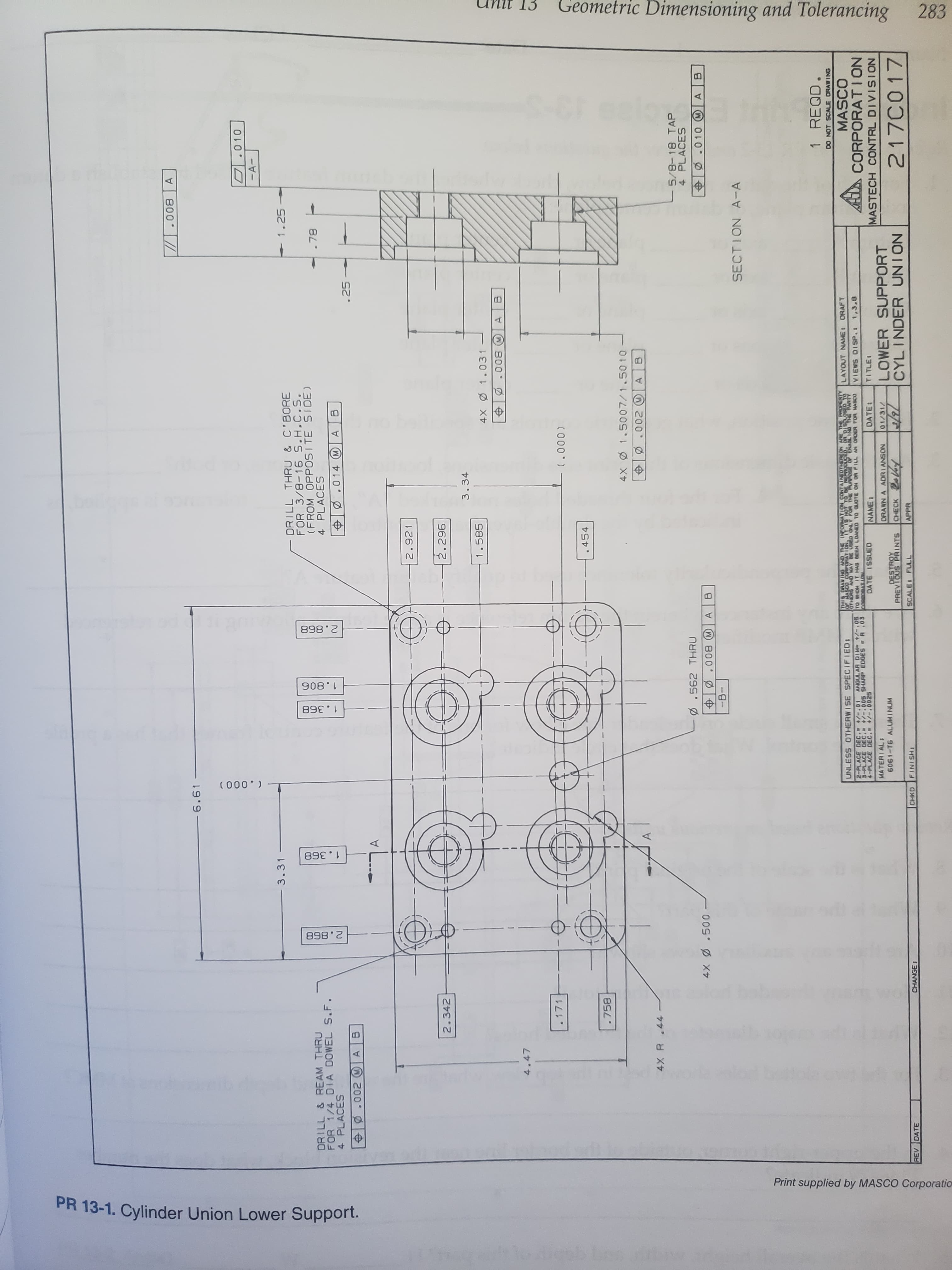

Transcribed Image Text:Geometric Dimensioning and Tolerancing

283

898 2

908

(000

893 386

898 2

Print supplied by MASCO Corporatio

PR 13-1. Cylinder Union Lower Support.

800

6.61

O.010

-A-

3.31

1.25

DRILL THRU & C'BORE

FOR 3/8-16 S.H.C.S.

(FROM OPPOSITE SIDE)

4 PLACES

DRILL & REAM THRU

FOR 1/4 DIA DOWEL S.F.

4 PLACES

.78

.014 M A

.002 A B

.25

L..

2.921

2.342

96 2

3.34

1.585

4X 1.031

800

4.47

.171

( 000 )

.454

.758

4X 1.5007/1.501 o

.002 A

4X R.44

- 5/8-18 TAP

4 PLACES

.562 THRU

Ø.010 A

B

0050

-B-

800

SECTION A-A

1 REQD.

DO NOT SCALE ORAWING

THIS DRAVING AND THE INFORMAYION CONTAINEDTHEREON ARE THE FROPERTY

OTHERS AND MAY 8SED ONLY POR TE FURPOSE OF ENABL INO THE PARTY

TO WHOM IT HAS BEEN LOANED TO QUOTE ON OR PILL AN OR0ER FOR MASCO

UNLESS OTHERWISE SPECIFIED

LAYOUT NAME ORAFT

MASCO

A CORPORATION

ANGUL AR DIM- +/-.05

2-PLACE DEC. -01

8-PLACE DEC. -.005 SHARP EDGES A .03

VIEWS DISP.

DATE ISSUED

NAME:

DATE:

TITLE

9200-/+ 30 d-

MATERIAL:

MASTECH CONTRL DIVISION

LOWER SUPPORT

CYLINDER UNION

ORAWN A ADRIANSON

01/31/

6061-T6 ALUMINUM

DESTROY

PREVIOUS PRINTS

217C017

CHECK

REV DATE

CHANGE:

CHKD

FINISH

SCALE FULL

APPR

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

International Edition---engineering Mechanics: St…

Mechanical Engineering

ISBN:

9781305501607

Author:

Andrew Pytel And Jaan Kiusalaas

Publisher:

CENGAGE L

International Edition---engineering Mechanics: St…

Mechanical Engineering

ISBN:

9781305501607

Author:

Andrew Pytel And Jaan Kiusalaas

Publisher:

CENGAGE L