Print Reading for Industry 432 Class Date Name Industry Print Exercise 22-2 Refier to the print PR 22-2 amd answer the questions belou 1. What is the total number of parts (not part numbers) required for this welded assembly? 2. What is the name and number of the part identified as item 3? 3 According to note 3, what section of the AWS D1.1 standard should be referenced for the 100% weld penetration? 4 What type of weld should be used to "tack" the parts associated with item 4 in place? 5. What process can be used after welding to blend the weld with the parts? 6. For the process in question 5, does the welding symbol indicate flat, convex, or concave? 7. A couple of the welding symbols have a circle on the symbol elbow. What does that mean? 8. Are there complete dimensions on the drawing detailing all measurements for the individual parts? 9. Unless specified, all welds are to be class Review questions based on previous units: 10. Are there cutting-plane lines shown on this print? 11. What scale are the main views on the original drawing? 12. How much does this part weigh after welded together? 13. What revision status was given to this print? 14. What is the length of each of the six spacers? 15. At what scale is the enlarged detail? Copyright Goodheart-Willcox Co., Inc. Welding Prints Unit 22 ВС128 N8 fiblaeo N D i no elodie va y biar wot 101 C 90 Tou @T Print supplied by Marathon LeTourneau Cc PR 22-2. Stress Relieved Sub-Str. Copyright Goodheart-Willcox Co., Inc. SLONTOI3 ECN DATE APPROVED ZONE REV DESCRIPTION ERT WF OO RELEASED BLENDED FILLET WELD 62 - I REF 무oz FULL SCALE WELD JO INT BLEND FILLET WELD HERE BY GRINDING REF WELD PROCEDURE NUMBER IS WEZ002SBUF WELD PROCEDURE NUMBER IS WEZ002SBUF Е (SEE INSPEC- TION NOTE) (SEE INSPEC- TION NOTE) BLEND FILLET WELD HERE BY GRINDING VTAC TYP 4 LOCATION NOT CRITICAL, FOR STRESS RELIEF ONY REF ITEM 5 USED ON ITEM 2 54 REF NMOHN SHINON SI ONY BC238 BACK ING BAR BC237 SPACER, TEMPO PLATE, INNER ROLL-UP, INNER PLATE, OUTER NOTE: BC236 Е BC235 NOTES: i. STRESS RELIEVE PER ERP 062 AFTER FABRICATION. 3. WELD TO BE COMPLETE JOINT PENETRATION (100%) UT TO SECTION 9 OF AWS DI.1 1992 EDITION. MAGNAFLUX PRIOR TO UT. NO CRACKS ALLOWED ALL WELDS CLASS IV UNLESS OTHERWISE SPECIFIED. (AWS D14.4) BC234 ITEM PART NO. QTY DESCRIPTION REVIEW AND APPROVAL FIRST USED ONVCONTRACT NO. THIS DRAWING AND ALL DATA THEREIN IS THE OINENSIONS ARE IN INCHES TOLERANCESI Marathon LeTourneau Company BR549 PROPERTY OF MARATHON LETOURNEAU COMPANY LONGVIEW, TEXAS IT IS CONIDENT LAL FG ENGR Longyie Division ANGLES 1 2 PLACE DECIMAL.03 O1-21 MDF NAO 12-9 SUB-STR, STRESS 12-9 REL IEVED ETALLURGISTROGERS 12-10 -01-9 SIO TMI030 30Vd E IND ENGR TROY FRACTIONAL a1/16 12-10 ENGA 12-10 PROD ENGA TOBI 3 JON IS O TOOL ENGR MDF OTY SUBJECT TO RETURN BC128 ON FOS 3IS 6-21 ON OAO SI ON ONVM30 NOen 12-10 J APPROVAL HJUK TEXTURE DESIGNATIONS APPLY BEFORE PLATING 6-21 ANY WAY DETRIMENTAL MATERIAL 8/1S 5022 LBs 00 TO OUR INTEREST SHEET 1 OF 1 SONIIVO HSINIA O

Print Reading for Industry 432 Class Date Name Industry Print Exercise 22-2 Refier to the print PR 22-2 amd answer the questions belou 1. What is the total number of parts (not part numbers) required for this welded assembly? 2. What is the name and number of the part identified as item 3? 3 According to note 3, what section of the AWS D1.1 standard should be referenced for the 100% weld penetration? 4 What type of weld should be used to "tack" the parts associated with item 4 in place? 5. What process can be used after welding to blend the weld with the parts? 6. For the process in question 5, does the welding symbol indicate flat, convex, or concave? 7. A couple of the welding symbols have a circle on the symbol elbow. What does that mean? 8. Are there complete dimensions on the drawing detailing all measurements for the individual parts? 9. Unless specified, all welds are to be class Review questions based on previous units: 10. Are there cutting-plane lines shown on this print? 11. What scale are the main views on the original drawing? 12. How much does this part weigh after welded together? 13. What revision status was given to this print? 14. What is the length of each of the six spacers? 15. At what scale is the enlarged detail? Copyright Goodheart-Willcox Co., Inc. Welding Prints Unit 22 ВС128 N8 fiblaeo N D i no elodie va y biar wot 101 C 90 Tou @T Print supplied by Marathon LeTourneau Cc PR 22-2. Stress Relieved Sub-Str. Copyright Goodheart-Willcox Co., Inc. SLONTOI3 ECN DATE APPROVED ZONE REV DESCRIPTION ERT WF OO RELEASED BLENDED FILLET WELD 62 - I REF 무oz FULL SCALE WELD JO INT BLEND FILLET WELD HERE BY GRINDING REF WELD PROCEDURE NUMBER IS WEZ002SBUF WELD PROCEDURE NUMBER IS WEZ002SBUF Е (SEE INSPEC- TION NOTE) (SEE INSPEC- TION NOTE) BLEND FILLET WELD HERE BY GRINDING VTAC TYP 4 LOCATION NOT CRITICAL, FOR STRESS RELIEF ONY REF ITEM 5 USED ON ITEM 2 54 REF NMOHN SHINON SI ONY BC238 BACK ING BAR BC237 SPACER, TEMPO PLATE, INNER ROLL-UP, INNER PLATE, OUTER NOTE: BC236 Е BC235 NOTES: i. STRESS RELIEVE PER ERP 062 AFTER FABRICATION. 3. WELD TO BE COMPLETE JOINT PENETRATION (100%) UT TO SECTION 9 OF AWS DI.1 1992 EDITION. MAGNAFLUX PRIOR TO UT. NO CRACKS ALLOWED ALL WELDS CLASS IV UNLESS OTHERWISE SPECIFIED. (AWS D14.4) BC234 ITEM PART NO. QTY DESCRIPTION REVIEW AND APPROVAL FIRST USED ONVCONTRACT NO. THIS DRAWING AND ALL DATA THEREIN IS THE OINENSIONS ARE IN INCHES TOLERANCESI Marathon LeTourneau Company BR549 PROPERTY OF MARATHON LETOURNEAU COMPANY LONGVIEW, TEXAS IT IS CONIDENT LAL FG ENGR Longyie Division ANGLES 1 2 PLACE DECIMAL.03 O1-21 MDF NAO 12-9 SUB-STR, STRESS 12-9 REL IEVED ETALLURGISTROGERS 12-10 -01-9 SIO TMI030 30Vd E IND ENGR TROY FRACTIONAL a1/16 12-10 ENGA 12-10 PROD ENGA TOBI 3 JON IS O TOOL ENGR MDF OTY SUBJECT TO RETURN BC128 ON FOS 3IS 6-21 ON OAO SI ON ONVM30 NOen 12-10 J APPROVAL HJUK TEXTURE DESIGNATIONS APPLY BEFORE PLATING 6-21 ANY WAY DETRIMENTAL MATERIAL 8/1S 5022 LBs 00 TO OUR INTEREST SHEET 1 OF 1 SONIIVO HSINIA O

Welding: Principles and Applications (MindTap Course List)

8th Edition

ISBN:9781305494695

Author:Larry Jeffus

Publisher:Larry Jeffus

Chapter12: Flux Cored Arc Welding Equipment, Setup, And Operation

Section: Chapter Questions

Problem 22R: Describe the meaning of each part of the following FCA welding electrode identification: E81T-5.

Related questions

Question

I need answers to parts 4, 5, and 6, pertaining to the print provided.

Transcribed Image Text:Print Reading for Industry

432

Class

Date

Name

Industry Print Exercise 22-2

Refier to the print PR 22-2 amd answer the questions belou

1. What is the total number of parts (not part numbers) required for this welded assembly?

2. What is the name and number of the part identified as item 3?

3 According to note 3, what section of the AWS D1.1 standard should be referenced for the 100% weld

penetration?

4 What type of weld should be used to "tack" the parts associated with item 4 in place?

5. What process can be used after welding to blend the weld with the parts?

6. For the process in question 5, does the welding symbol indicate flat, convex, or concave?

7. A couple of the welding symbols have a circle on the symbol elbow. What does that mean?

8. Are there complete dimensions on the drawing detailing all measurements for the individual parts?

9. Unless specified, all welds are to be class

Review questions based on previous units:

10. Are there cutting-plane lines shown on this print?

11. What scale are the main views on the original drawing?

12. How much does this part weigh after welded together?

13. What revision status was given to this print?

14. What is the length of each of the six spacers?

15. At what scale is the enlarged detail?

Copyright Goodheart-Willcox Co., Inc.

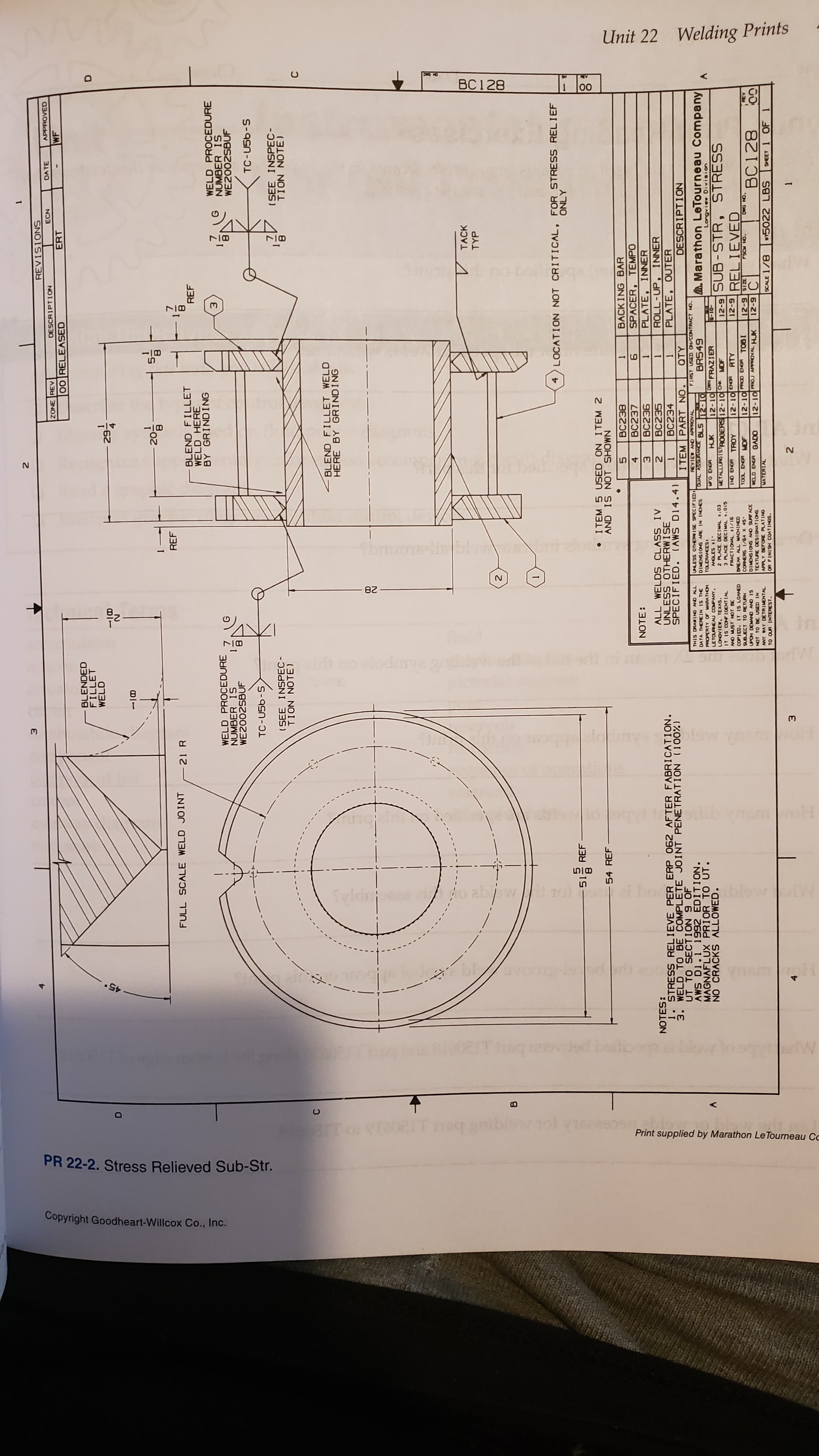

Transcribed Image Text:Welding Prints

Unit 22

ВС128

N8

fiblaeo

N D

i no elodie

va y

biar

wot

101

C

90

Tou @T

Print supplied by Marathon LeTourneau Cc

PR 22-2. Stress Relieved Sub-Str.

Copyright Goodheart-Willcox Co., Inc.

SLONTOI3

ECN

DATE

APPROVED

ZONE REV

DESCRIPTION

ERT

WF

OO RELEASED

BLENDED

FILLET

WELD

62

- I

REF

무oz

FULL SCALE WELD JO INT

BLEND FILLET

WELD HERE

BY GRINDING

REF

WELD PROCEDURE

NUMBER IS

WEZ002SBUF

WELD PROCEDURE

NUMBER IS

WEZ002SBUF

Е

(SEE INSPEC-

TION NOTE)

(SEE INSPEC-

TION NOTE)

BLEND FILLET WELD

HERE BY GRINDING

VTAC

TYP

4 LOCATION NOT CRITICAL, FOR STRESS RELIEF

ONY

REF

ITEM 5 USED ON ITEM 2

54 REF

NMOHN SHINON SI ONY

BC238

BACK ING BAR

BC237

SPACER, TEMPO

PLATE, INNER

ROLL-UP, INNER

PLATE, OUTER

NOTE:

BC236

Е

BC235

NOTES:

i. STRESS RELIEVE PER ERP 062 AFTER FABRICATION.

3. WELD TO BE COMPLETE JOINT PENETRATION (100%)

UT TO SECTION 9 OF

AWS DI.1 1992 EDITION.

MAGNAFLUX PRIOR TO UT.

NO CRACKS ALLOWED

ALL WELDS CLASS IV

UNLESS OTHERWISE

SPECIFIED. (AWS D14.4)

BC234

ITEM PART NO.

QTY

DESCRIPTION

REVIEW AND APPROVAL

FIRST USED ONVCONTRACT NO.

THIS DRAWING AND ALL

DATA THEREIN IS THE

OINENSIONS ARE IN INCHES

TOLERANCESI

Marathon LeTourneau Company

BR549

PROPERTY OF MARATHON

LETOURNEAU COMPANY

LONGVIEW, TEXAS

IT IS CONIDENT LAL

FG ENGR

Longyie Division

ANGLES 1

2 PLACE DECIMAL.03

O1-21

MDF

NAO

12-9 SUB-STR, STRESS

12-9 REL IEVED

ETALLURGISTROGERS 12-10

-01-9

SIO TMI030 30Vd E

IND ENGR TROY

FRACTIONAL a1/16

12-10 ENGA

12-10 PROD ENGA TOBI

3 JON IS O

TOOL ENGR MDF

OTY

SUBJECT TO RETURN

BC128

ON FOS

3IS 6-21

ON OAO

SI ON ONVM30 NOen

12-10 J APPROVAL HJUK

TEXTURE DESIGNATIONS

APPLY BEFORE PLATING

6-21

ANY WAY DETRIMENTAL

MATERIAL

8/1S

5022 LBs

00

TO OUR INTEREST

SHEET 1 OF 1

SONIIVO HSINIA O

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning