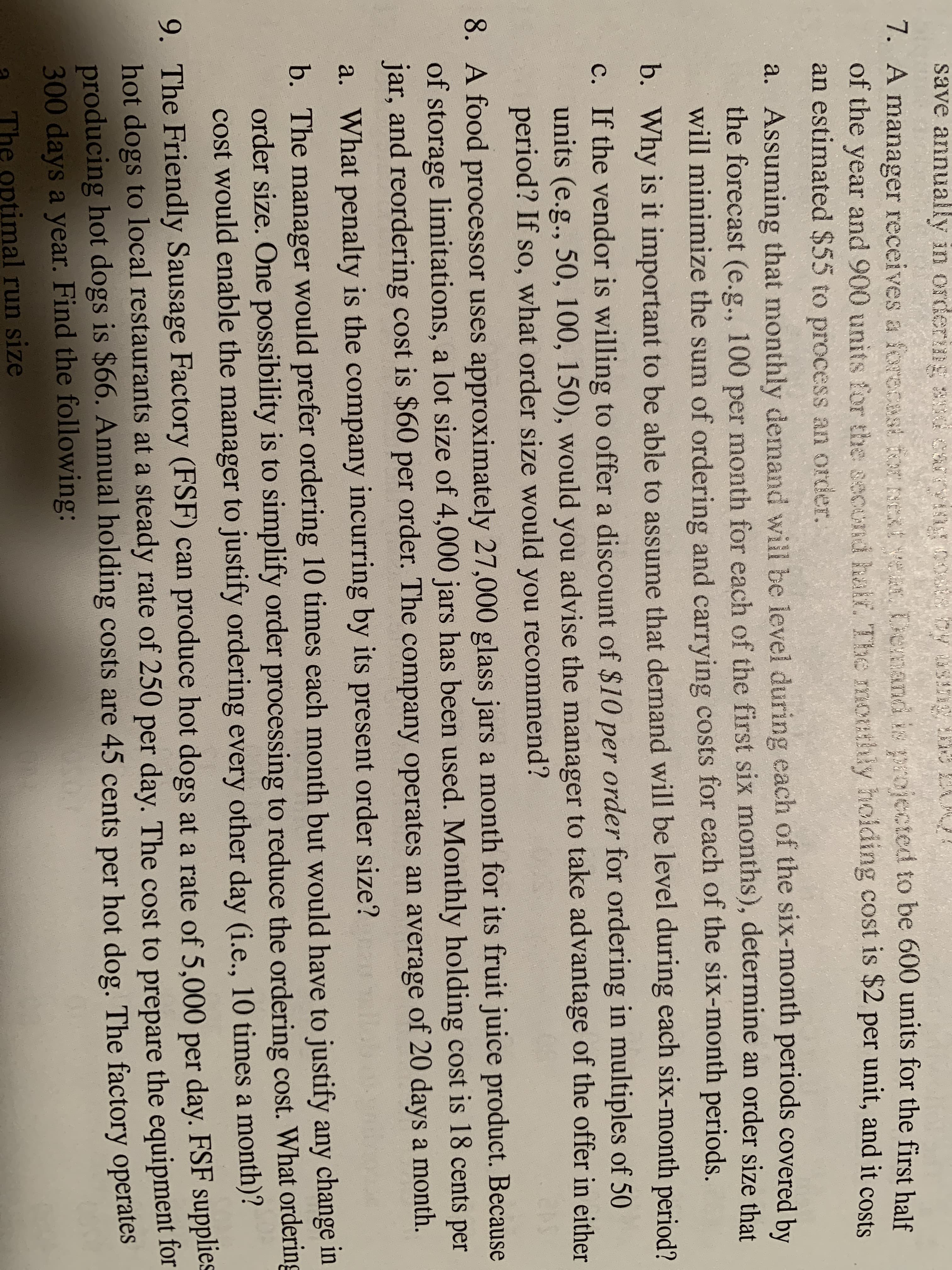

save annually in ordering sud carryit 1. A manager receives a forecast tor text Ne aa. Demand is projected to be 600 units for the first half of the year and 900 units for the secund half. The mothly holding cost is $2 per unit, and it costs an estimated $55 to process an order. a. Assuming that monthly demand will be level during each of the six-month periods covered by the forecast (e.g., 100 per month for each of the first six months), determine an order size that will minimize the sum of ordering and carrying costs for each of the six-month periods. b. Why is it important to be able to assume that demand will be level during each six-month period? c. If the vendor is willing to offer a discount of $10 per order for ordering in multiples of 50 units (e.g., 50, 100, 150), would you advise the manager to take advantage of the offer in either period? If so, what order size would you recommend? 8. A food processor uses approximately 27,000 glass jars a month for its fruit juice product. Because of storage limitations, a lot size of 4,000 jars has been used. Monthly holding cost is 18 cents per jar, and reordering cost is $60 per order. The company operates an average of 20 days a month. a. What penalty is the company incurring by its present order size? han b. The manager would prefer ordering 10 times each month but would have to justify any change in order size. One possibility is to simplify order processing to reduce the ordering cost. What ordering cost would enable the manager to justify ordering every other day (i.e., 10 times a month)? 9. The Friendly Sausage Factory (FSF) can produce hot dogs at a rate of 5,000 per day. FSF supplies hot dogs to local restaurants at a steady rate of 250 per day. The cost to prepare the equipment for producing hot dogs is $66. Annual holding costs are 45 cents per hot dog. The factory operates 300 days a year. Find the following : The optimal run size APH 6 2 ी OPERATIONS MANAGEMENT Thirteenth Edition WILLIAM J. STEVENSON Mc Graw Hill Education $0E

Critical Path Method

The critical path is the longest succession of tasks that has to be successfully completed to conclude a project entirely. The tasks involved in the sequence are called critical activities, as any task getting delayed will result in the whole project getting delayed. To determine the time duration of a project, the critical path has to be identified. The critical path method or CPM is used by project managers to evaluate the least amount of time required to finish each task with the least amount of delay.

Cost Analysis

The entire idea of cost of production or definition of production cost is applied corresponding or we can say that it is related to investment or money cost. Money cost or investment refers to any money expenditure which the firm or supplier or producer undertakes in purchasing or hiring factor of production or factor services.

Inventory Management

Inventory management is the process or system of handling all the goods that an organization owns. In simpler terms, inventory management deals with how a company orders, stores, and uses its goods.

Project Management

Project Management is all about management and optimum utilization of the resources in the best possible manner to develop the software as per the requirement of the client. Here the Project refers to the development of software to meet the end objective of the client by providing the required product or service within a specified Period of time and ensuring high quality. This can be done by managing all the available resources. In short, it can be defined as an application of knowledge, skills, tools, and techniques to meet the objective of the Project. It is the duty of a Project Manager to achieve the objective of the Project as per the specifications given by the client.

I need help with question 13.8, chapter 13, question 8

Trending now

This is a popular solution!

Step by step

Solved in 8 steps with 6 images