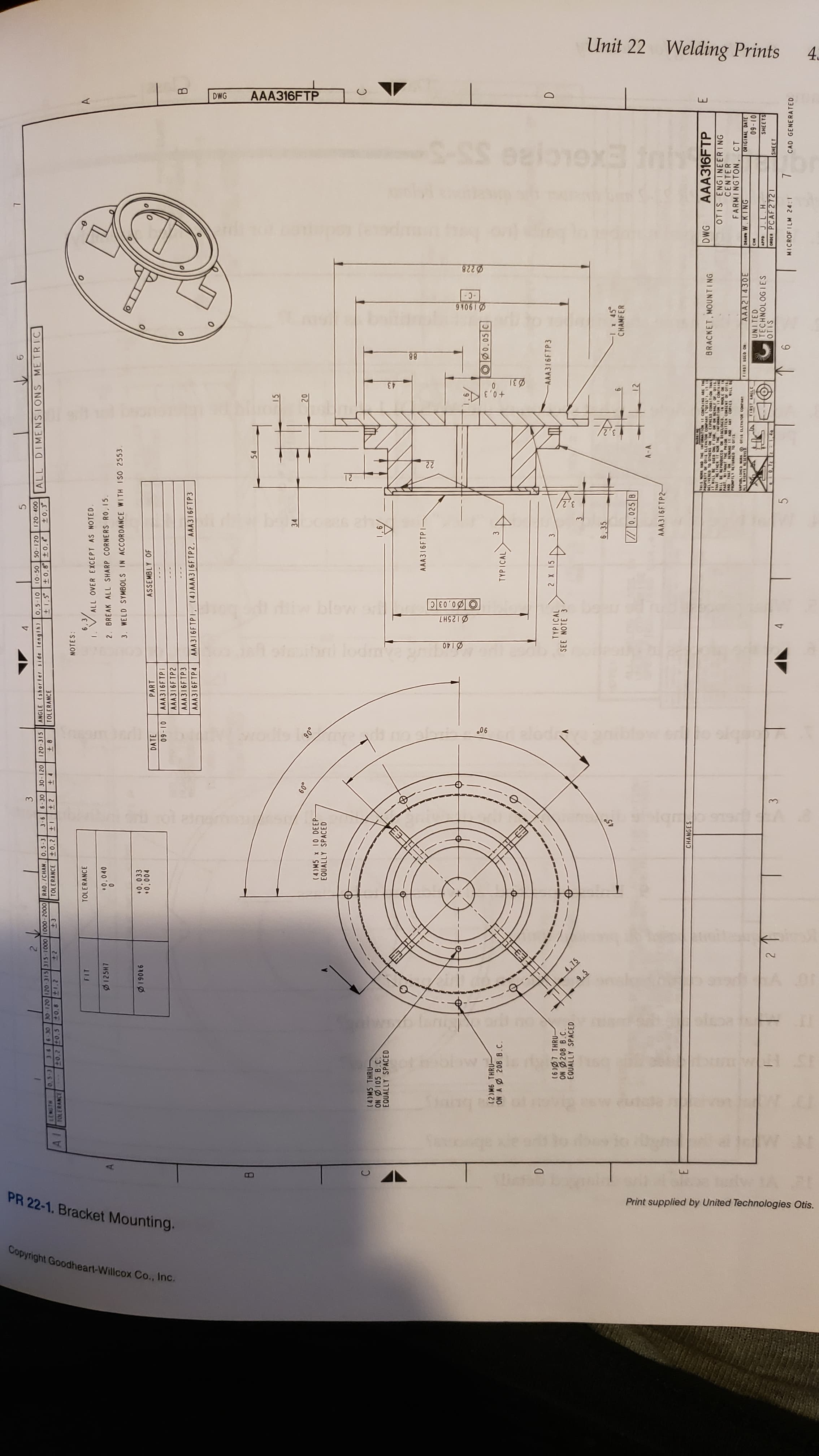

Unit 22 Welding Prints 4 AAA316FTP DWG 228 31 +0,3 43 22 TZ blow E0OO Ø125H7 bi lodm Ø140 Su 9.5 e 0 o PR 22-1. Bracket Mounting. Print supplied by United Technologies Otis. Copyright Goodheart-Willcox Co., Inc. 120-400 t0,3 50-120 3-6 6-30 ANGLE (shor ler side length) O,5-10 10-50 ALL DIMENSIONS METRIC 30-120 120-315 O.5-3 A OLERANCE 3-6 6-30 30 120 120 315 315 10000 1000-2000 RAD. /CHAN 0.5-3 40.2 0.5 +8 TOLERANCE + 0,8 t0, +0.8 1,2 +3 TOLERANCE 0.2 + 2 24 NOTES: TOLERANCE 6,3 ALL OVER EXCEPT AS NOTED. 2. BREAK ALL SHARP CORNERS RO, I15 FIT 125H7 0.040 0 3. WELD SYMBOLS IN ACCORDANCE WI TH ISO 2553. 0.033 93061 DATE PART ASSEMBLY OF AAA316FTPI 01-60 AAA316FTP2 AAA316FTP3 B AAA316FTP4 AAA316FTPI, (4)AAA316FTP2, AAA316FTP3 54 15 34 .0.9 20 (4)M5 x 10 DEEP- EQUALLY SPACED 06 (4)M5 THRU- ON 105 B.C EQUALLY SPACED 9 AAA316FTPI 9 1 O0.05 C (2)M6 THRU- ON A 208 B.C TYP ICAL 4c AAA316FTP3 (6)7 THRU- ON 208 B.C EQUALLY SPACED 3 4,15 TYPICAL SEE NOTE 3 4512 6,35 I x 45 CHAMFER Q.025 B A-A AAA316FTP2- CHANGES AAA316FTP SINL BRACKET, MOUNTING DWG OLIVEREO T0 OTNERS ON THE EIPRLSS CONDITIO THA OTIS ENGINEERING CENTER FARMINGTON PART CT ww eti10nn AN SANDIN AAA21 430E 0RAN W.KING ORIGINAL DATE NO 01sn is81 UNITED 2 T APPO J. L.H. ORDER PCAF 2 721 01-60 SHEETS 3 OTIS SHEET MICROFILM 24:1 CAD GENERATED

Unit 22 Welding Prints 4 AAA316FTP DWG 228 31 +0,3 43 22 TZ blow E0OO Ø125H7 bi lodm Ø140 Su 9.5 e 0 o PR 22-1. Bracket Mounting. Print supplied by United Technologies Otis. Copyright Goodheart-Willcox Co., Inc. 120-400 t0,3 50-120 3-6 6-30 ANGLE (shor ler side length) O,5-10 10-50 ALL DIMENSIONS METRIC 30-120 120-315 O.5-3 A OLERANCE 3-6 6-30 30 120 120 315 315 10000 1000-2000 RAD. /CHAN 0.5-3 40.2 0.5 +8 TOLERANCE + 0,8 t0, +0.8 1,2 +3 TOLERANCE 0.2 + 2 24 NOTES: TOLERANCE 6,3 ALL OVER EXCEPT AS NOTED. 2. BREAK ALL SHARP CORNERS RO, I15 FIT 125H7 0.040 0 3. WELD SYMBOLS IN ACCORDANCE WI TH ISO 2553. 0.033 93061 DATE PART ASSEMBLY OF AAA316FTPI 01-60 AAA316FTP2 AAA316FTP3 B AAA316FTP4 AAA316FTPI, (4)AAA316FTP2, AAA316FTP3 54 15 34 .0.9 20 (4)M5 x 10 DEEP- EQUALLY SPACED 06 (4)M5 THRU- ON 105 B.C EQUALLY SPACED 9 AAA316FTPI 9 1 O0.05 C (2)M6 THRU- ON A 208 B.C TYP ICAL 4c AAA316FTP3 (6)7 THRU- ON 208 B.C EQUALLY SPACED 3 4,15 TYPICAL SEE NOTE 3 4512 6,35 I x 45 CHAMFER Q.025 B A-A AAA316FTP2- CHANGES AAA316FTP SINL BRACKET, MOUNTING DWG OLIVEREO T0 OTNERS ON THE EIPRLSS CONDITIO THA OTIS ENGINEERING CENTER FARMINGTON PART CT ww eti10nn AN SANDIN AAA21 430E 0RAN W.KING ORIGINAL DATE NO 01sn is81 UNITED 2 T APPO J. L.H. ORDER PCAF 2 721 01-60 SHEETS 3 OTIS SHEET MICROFILM 24:1 CAD GENERATED

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need answers to parts 1, 2, and 3, pertaining to the print provided.

Transcribed Image Text:Unit 22

Welding Prints

4

AAA316FTP

DWG

228

31

+0,3

43

22

TZ

blow

E0OO

Ø125H7

bi lodm

Ø140

Su

9.5

e

0 o

PR 22-1. Bracket Mounting.

Print supplied by United Technologies Otis.

Copyright Goodheart-Willcox Co., Inc.

120-400

t0,3

50-120

3-6 6-30

ANGLE (shor ler side length) O,5-10 10-50

ALL DIMENSIONS METRIC

30-120

120-315

O.5-3

A OLERANCE

3-6 6-30 30 120 120 315 315 10000 1000-2000 RAD. /CHAN 0.5-3

40.2 0.5

+8

TOLERANCE

+ 0,8 t0,

+0.8 1,2

+3

TOLERANCE 0.2

+ 2

24

NOTES:

TOLERANCE

6,3

ALL OVER EXCEPT AS NOTED.

2. BREAK ALL SHARP CORNERS RO, I15

FIT

125H7

0.040

0

3. WELD SYMBOLS IN ACCORDANCE WI TH ISO 2553.

0.033

93061

DATE

PART

ASSEMBLY OF

AAA316FTPI

01-60

AAA316FTP2

AAA316FTP3

B

AAA316FTP4

AAA316FTPI, (4)AAA316FTP2, AAA316FTP3

54

15

34

.0.9

20

(4)M5 x 10 DEEP-

EQUALLY SPACED

06

(4)M5 THRU-

ON 105 B.C

EQUALLY SPACED

9

AAA316FTPI

9 1

O0.05 C

(2)M6 THRU-

ON A 208 B.C

TYP ICAL

4c

AAA316FTP3

(6)7 THRU-

ON 208 B.C

EQUALLY SPACED

3

4,15

TYPICAL

SEE NOTE 3

4512

6,35

I x 45

CHAMFER

Q.025 B

A-A

AAA316FTP2-

CHANGES

AAA316FTP

SINL

BRACKET, MOUNTING

DWG

OLIVEREO T0 OTNERS ON THE EIPRLSS CONDITIO THA

OTIS ENGINEERING

CENTER

FARMINGTON

PART

CT

ww eti10nn

AN SANDIN

AAA21 430E

0RAN W.KING

ORIGINAL DATE

NO 01sn is81

UNITED

2 T

APPO J. L.H.

ORDER PCAF 2 721

01-60

SHEETS

3

OTIS

SHEET

MICROFILM 24:1

CAD GENERATED

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY