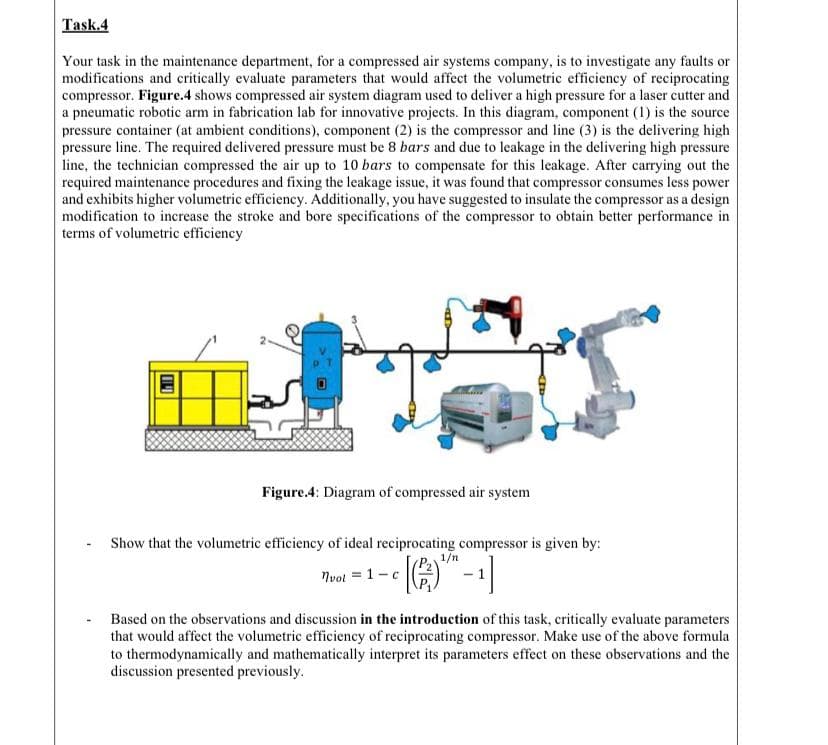

Your task in the maintenance department, for a compressed air systems company, is to investigate any faults or modifications and critically evaluate parameters that would affect the volumetric efficiency of reciprocating compressor. Figure.4 shows compressed air system diagram used to deliver a high pressure for a laser cutter and a pneumatic robotic arm in fabrication lab for innovative projects. In this diagram, component (1) is the source pressure container (at ambient conditions), component (2) is the compressor and line (3) is the delivering high pressure line. The required delivered pressure must be 8 bars and due to leakage in the delivering high pressure line, the technician compressed the air up to 10 bars to compensate for this leakage. After carrying out the required maintenance procedures and fixing the leakage issue, it was found that compressor consumes less power and exhibits higher volumetric efficiency. Additionally, you have suggested to insulate the compressor as a design modification to increase the stroke and bore specifications of the compressor to obtain better performance in terms of volumetric efficiency Figure.4: Diagram of compressed air system Show that the volumetric efficiency of ideal reciprocating compressor is given by: Nvot = 1-c Based on the observations and discussion in the introduction of this task, critically evaluate parameters that would affect the volumetric efficiency of reciprocating compressor. Make use of the above formula to thermodynamically and mathematically interpret its parameters effect on these observations and the discussion presented previously.

Your task in the maintenance department, for a compressed air systems company, is to investigate any faults or modifications and critically evaluate parameters that would affect the volumetric efficiency of reciprocating compressor. Figure.4 shows compressed air system diagram used to deliver a high pressure for a laser cutter and a pneumatic robotic arm in fabrication lab for innovative projects. In this diagram, component (1) is the source pressure container (at ambient conditions), component (2) is the compressor and line (3) is the delivering high pressure line. The required delivered pressure must be 8 bars and due to leakage in the delivering high pressure line, the technician compressed the air up to 10 bars to compensate for this leakage. After carrying out the required maintenance procedures and fixing the leakage issue, it was found that compressor consumes less power and exhibits higher volumetric efficiency. Additionally, you have suggested to insulate the compressor as a design modification to increase the stroke and bore specifications of the compressor to obtain better performance in terms of volumetric efficiency Figure.4: Diagram of compressed air system Show that the volumetric efficiency of ideal reciprocating compressor is given by: Nvot = 1-c Based on the observations and discussion in the introduction of this task, critically evaluate parameters that would affect the volumetric efficiency of reciprocating compressor. Make use of the above formula to thermodynamically and mathematically interpret its parameters effect on these observations and the discussion presented previously.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I have uploaded many times this question. Please solve it.

Transcribed Image Text:Your task in the maintenance department, for a compressed air systems company, is to investigate any faults or

modifications and critically evaluate parameters that would affect the volumetric efficiency of reciprocating

compressor. Figure.4 shows compressed air system diagram used to deliver a high pressure for a laser cutter and

a pneumatic robotic arm in fabrication lab for innovative projects. In this diagram, component (1) is the source

pressure container (at ambient conditions), component (2) is the compressor and line (3) is the delivering high

pressure line. The required delivered pressure must be 8 bars and due to leakage in the delivering high pressure

line, the technician compressed the air up to 10 bars to compensate for this leakage. After carrying out the

required maintenance procedures and fixing the leakage issue, it was found that compressor consumes less power

and exhibits higher volumetric efficiency. Additionally, you have suggested to insulate the compressor as a design

modification to increase the stroke and bore specifications of the compressor to obtain better performance in

terms of volumetric efficiency

Figure.4: Diagram of compressed air system

Show that the volumetric efficiency of ideal reciprocating compressor is given by:

Nvot = 1-c

Based on the observations and discussion in the introduction of this task, critically evaluate parameters

that would affect the volumetric efficiency of reciprocating compressor. Make use of the above formula

to thermodynamically and mathematically interpret its parameters effect on these observations and the

discussion presented previously.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 6 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY