Reconsider Prob. 10–83. Determine which components of the combined cycle are the most wasteful of work potential.

10–83 A combined gas–steam power cycle uses a simple gas turbine for the topping cycle and simple Rankine cycle for the bottoming cycle. Atmospheric air enters the gas turbine at 101 kPa and 20°C, and the maximum gas cycle temperature is 1100°C. The compressor pressure ratio is 8; the compressor isentropic efficiency is 85 percent; and the gas turbine isentropic efficiency is 90 percent. The gas stream leaves the heat exchanger at the saturation temperature of the steam flowing through the heat exchanger. Steam flows through the heat exchanger with a pressure of 6000 kPa and leaves at 320°C. The steam-cycle condenser operates at 20 kPa, and the isentropic efficiency of the steam turbine is 90 percent. Determine the mass flow rate of air through the air compressor required for this system to produce 100 MW of power. Use constant specific heats for air at room temperature.

Which component of the combined cycle is the most wasteful of work potential.

Answer to Problem 85P

The combustor of the gas-steam cycle has largest exergy destruction

Explanation of Solution

Show the

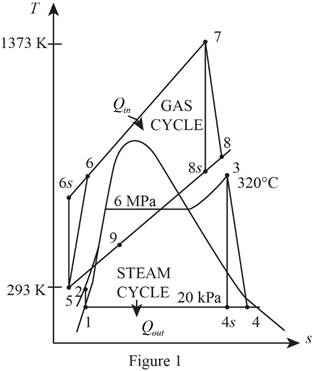

Refer Figure 1.

Consider the gas cycle (topping cycle) and their respective process states such as 5, 6,

Write the temperature and pressure relation at isentropic state and for the process 5-6-

Here, the temperature is

Write the formula for isentropic efficiency of compressor for the process 5-6-

Here, the enthalpy is

Rearrange and rewrite the equation (II) to obtain

Write the temperature and pressure relation at isentropic state and for the process 7-8-

Write the formula for isentropic efficiency of gas turbine

Rearrange and rewrite the equation (V) to obtain

At state 9: (heat exchanger)

The temperature

Refer Table A-5, “Saturated water-Pressure table”.

The saturation temperature corresponding to the pressure of

Refer Figure 1.

Consider the steam cycle (bottoming cycle) and their respective process states such as 1, 2, 3, 4,

At state 1:

The water exits the condenser as a saturated liquid at the pressure of

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

At state 2:

Write the formula for work done by the pump during process 1-2.

Here, the specific volume is

Write the formula for enthalpy

At state 3: (Turbine inlet)

The steam enters the turbine as superheated vapour.

Refer Table A-6, “Superheated water”.

The enthalpy

From Figure 1,

At state 4: (Turbine exit or condenser inlet)

The steam exits the condenser as a saturated liquid at the pressure of

The quality of water at the exit of the turbine is expressed as follows.

The enthalpy at state

Here, the enthalpy is

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following properties corresponding to the pressure of

Write the formula for isentropic efficiency of the steam turbine

Rearrange the Equation (XI) to obtain the enthalpy

Write the formula for net work output of the gas cycle.

Here, the specific heat of air at constant pressure is

Write the formula for net work output of the steam cycle.

Write the general energy rate balance equation.

Here, the rate of energy in is

Consider the heat exchanger operates on steady state. Hence, the rate of change in net energy of the system is zero.

The Equation (XV) is reduced as follows for the heat exchanger.

Here, the mass flow rate of air is

Write the formula for mass flow rate of air through the compressor.

Write the formula for the exergy destruction for the process 3-4 (turbine).

Write the formula for the exergy destruction for the process 4-1 (condenser).

Write the formula for the exergy destruction for heat exchanger.

Write the formula for the exergy destruction for the process 5-6 (compressor).

Write the formula for the exergy destruction for the process 6-7 (combustion chamber).

Write the formula for the exergy destruction for the process 7-8 (gas turbine).

Here, the specific heat at constant pressure of air is

Refer Table A-2, “Ideal-gas specific heats of various common gases”.

The specific heat at constant pressure

Conclusion:

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Here,

Substitute

Substitute

Equation (X).

Substitute

Substitute

Substitute

Equation (XIV).

Substitute

When, the mass flow rate of air is

Substitute

Thus, the Equation (XXIV) describes that

Substitute

Thus, the mass flow rate of the air through the air compressor required for this system to produce

Substitute

Consider the process 1 to 2 (Pump).

Here, the pump is isentropic. Hence the exergy destruction during the process 1-2 is zero.

Consider the process 3 to 4 (steam turbine).

Here,

Substitute

Thus, the exergy destruction during process 3-4 is

Substitute

Substitute

Substitute

Substitute

Substitute

The calculated exergy destruction value is greater for component combustor that is

Hence, the combustor of the gas-steam cycle has largest exergy destruction of all other components and that is the most wasteful of work potential.

Want to see more full solutions like this?

Chapter 10 Solutions

Thermodynamics: An Engineering Approach

Additional Engineering Textbook Solutions

Heating Ventilating and Air Conditioning: Analysis and Design

Fluid Mechanics: Fundamentals and Applications

Vector Mechanics for Engineers: Statics and Dynamics

Manufacturing Engineering & Technology

Engineering Mechanics: Statics

Statics and Mechanics of Materials

- How does the thermal efficiency of an ideal Otto cycle change with the compression ratio of the engine and the specific heat ratio of the working fluid?arrow_forwardA gas-turbine power plant operates on the simple Brayton cycle between the pressure limits of 100 and 1600 kPa. The working fluid is air, which enters the compressor at 40C at a rate of 850 m3/min and leaves the turbine at 650C. Using variable specific heats for air and assuming a compressor isentropic efficiency of 85 percent and a turbine isentropic efficiency of 88 percent, determine (a) the net power output, (b) the back work ratio, and (c) the thermal efficiency.arrow_forwardConsider a steam power plant that operates on the ideal reheat Rankine cycle. The plant maintains the boiler at 5400 kPa, the reheat section 1100 kPa, and the condenser at 10 kPa. The mixture quality at the exit of both turbines is 94 %. Determine the following values. (1) The specific enthalpy at the exit of the high-pressure turbine. (2) The specific entropy at the exit of the high-pressure turbine. (3) The temperature at the inlet of the high-pressure turbine. (4) The temperature at the inlet of the low-pressure turbine. (5) The thermal efficiency of the cycle.arrow_forward

- A gas-turbine power plant operates on the simple Brayton cycle between the pressure limits of 100 and 1200 kPa. The working fluid is air, which enters the compressor at 30°C at a rate of 150 m3/min and leaves the turbine at 500°C. Using constant specific heats for air and assuming a compressor isentropic efficiency of 82 percent and a turbine isentropic efficiency of 88 percent, determine (a) the net power output, (b) the work ratio, and (c) the thermal efficiency.arrow_forwardA gas-turbine power plant operates on the simple Brayton cycle between the pressure limits of 100 and 1600 kPa. The working fluid is air, which enters the compressor at 40°C at a rate of 850 m3 /min and leaves the turbine at 650°C. Assuming a compressor isentropic efficiency of 85 percent and a turbine isentropic efficiency of 88 percent, determine the back work ratio.arrow_forwardA brayton cycle with regeneration using air as the working fluid has a pressure ratio of 5. The minimum and maximum temperatures in the cycle are 360 and 1250 K. Assuming an isentropic efficiency of 80% for the compressor and 85% for the turbine, an effectiveness of 70% for the regenerator, a source temperature of 1200 K, an ambient temperature of 298 K. and an ambient pressure of 100 kPa, determine the following1- The air temperature at the turbine exit2- The net work output3- The thermal efficiency4- The total energy destruction5- The energy of the exhaust gases at the exit of the regeneratorarrow_forward

- A steam power plant operates on an ideal Rankine cycle with two stages of reheat and has a net power output of 75 MW. Steam enters all three stages of the turbine at 550C. The maximum pressure in the cycle is 10 MPa, and the minimum pressure is 30 kPa. Steam is reheated at 4 MPa the first time and at 2 MPa the second time. Show the cycle on a T-s diagram with respect to saturation lines, and determine (a) the thermal efficiency of the cycle, and (b) the mass flow rate of the steam.arrow_forwardConsider a steam power plant that operates on a reheat Rankine cycle and has a net power output of 80 MW. Steam enters the high-pressure turbine at 10 MPa and 500°C and the low-pressure turbine at 1 MPa and 500°C. Steam leaves the condenser as a saturated liquid at a pressure of 10 kPa. The isentropic efficiency of the turbine is 80%, and that of the pump is 95 %. Show the cycle on a T-s diagram with respect to saturation lines, and determine (a)the quality (or temperature, if superheated) of the steam at the turbine exit, (b)the thermal efficiency of the cycle, and (c)the mass flow rate of the steam.arrow_forwardA Brayton cycle with regeneration using air as the working fluid has a pressure ratio of 7. The minimum and maximum temperatures in the cycle are 310 and 1150 K. Assuming an isentropic efficiency of 75 percent for the compressor and 82 percent for the turbine and an effectiveness of 65 percent for the regenerator, determine the thermal efficiency. Use variable specific heats.arrow_forward

- An Otto cycle with air as the working fluid has a compression ratio of 10.4. Under cold-air-standard conditions, the thermal efficiency of this cycle is (a) 10 percent (b) 39 percent (c) 61 percent (d) 79 percent (e) 82 percentarrow_forwardIn an ideal Otto cycle, air is compressed from 1.20 kg/m3 and 2.2 to 0.26 L, and the net work output of the cycle is 440 kJ/kg. The mean effective pressure (MEP) for this cycle is (a) 612 kPa (b) 599 kPa (c) 528 kPa (d) 416 kPa (e) 367 kPaarrow_forwardA Brayton cycle with regeneration using air as the working fluid has a pressure ration of 10. The minimum and maximum temperatures in the cycle are 303 and 1073 K. Assuming an isentropic efficiency of 87% for the compressor and 93% for the turbine and a total power output of 115 kW. The gas leaving the regenerator is 10 K cooler than the hot exhaust gases entering the regenerator. Determine the rates of heat addition and rejection to and from the gas turbine.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY