Concept explainers

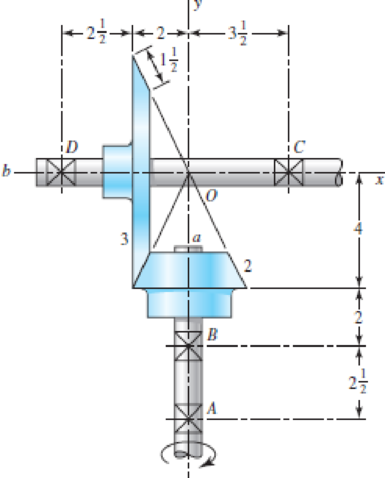

The figure shows a 16T 20° straight bevel pinion driving a 32T gear, and the location of the bearing centerlines. Pinion shaft a receives 2.5 hp at 240 rev/min. Determine the bearing reactions at A and B if A is to take both radial and thrust loads.

Problem 13–43

Dimensions in inches.

The bearing reaction at

The bearing reaction at

Answer to Problem 43P

The bearing reaction at

The bearing reaction at

Explanation of Solution

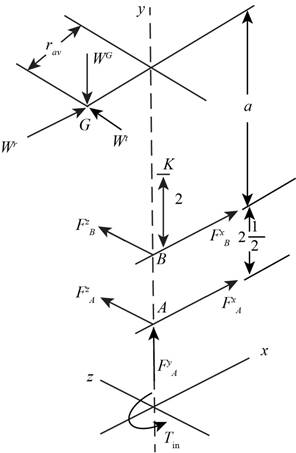

The figure below shows the forces acting at the bevel gear and pinion assembly.

Figure-(1)

Write the expression for the input torque.

Here, the power is

Write the expression for the pitch angle for gear 2.

Here, the distance between the gear 3 and y axis is

Write the expression fort the pitch radius at the mid-point of the bevel gear.

Here, the lateral side of the gear 3 is

Write the expression for the tangential load.

Write the expression for the pitch angle for gear 3.

Write the expression for the radial load.

Here, the pressure angle is

Write the expression for the axial load.

Write the expression of the load in vector form.

Calculate the value of

Write the expression for the position vector of

Here, the distance between the points

Write the expression for the position vector of

Write the expression for the force on the bearing

Here, the force on bearing

Write the expression for the moment about gear 4 in vector form.

Write the expression for the force equilibrium for the set of bearings.

Substitute

Conclusion:

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Compare the

Compare the

Compare the

Substitute

Thus, the bearing reaction at

Substitute

Thus, the bearing reaction at

Want to see more full solutions like this?

Chapter 13 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- A steel shaft 800 mm long transmitting 15 kW at 400 r.p.m. is supported at two bearings at the twoends. A gear wheel having 80 teeth and 500 mm pitch circle diameter is mounted at 200 mm from theleft hand side bearing and receives power from a pinion meshing with it. The axis of pinion and gearlie in the horizontal plane. A pulley of 300 mm diameter is mounted at 200 mm from right hand sidebearing and is used for transmitting power by a belt. The belt drive is inclined at 30° to the vertical inthe forward direction. The belt lap angle is 180 degrees. The coefficient of friction between belt andpulley is 0.3. Design and sketch the arrangement of the shaft assuming the values of safe stresses as :τ = 55 MPa; σt= 80 MPa. Take torsion and bending factor 1.5 and 2 respectively.arrow_forwardA straight tooth spur pinion has a 19 tooth pinion rotating at a speed of 1640 rpm. The driven gear will be rotating at a speed of 480 rpm. If the module of the pinion is 2,5 mm and pressure angle is 25 degree; Evaluate the outer diameter (mm) of the gear. A) 158,125 B) 157,5 C) 160 D) 162,5 E) 160,625arrow_forwardThe figure shows a double-reduction helical gearset. Pinion 2 is the driver, and it receives a torque of 1200 Ibf • in from its shaft in the direction shown. Pinion 2 has a normal diametral pitch of 8 teeth/in, 14 teeth, and a normal pressure angle of 20° and is cut right-handed with a helix angle of 30°. The mating gear 3 on shaft b has 36 teeth. Gear 4, which is the driver for the second pair of gears in the train, has a normal diametral pitch of 3 teeth/in, 15 teeth, and a normal pressure angle of 20° and is cut left-handed with a helix angle of 15°. Mating gear S has 45 teeth. Find the magnitude and direction of the force exerted by the bearings C and D on shaft b if bearing C can take only a radial load while bearing D is mounted to take both radial and thrust loads.arrow_forward

- A 17-tooth 20° pressure angle spur pinion rotates at 1800 rev/min and transmits 4 hp to a 52-tooth disk gear. The diametral pitch is 10 teeth/in, the face width 1.5 in, and the quality standard is No. 6. The gears are straddle-mounted with bearings immediately adjacent. The pinion is a grade 1 steel with a hardness of 240 Brinell tooth surface and through-hardened core. The gear is steel, through-hardened also, grade 1 material, with a Brinell hardness of 200, tooth surface and core. Poisson's ratio is 0.30, Jp = 0.30, JG = 0.40, and Young's modulus is 30(10°) psi. The loading is smooth because of motor and load. Assume a pinion life of 108 cycles and a reliability of 0.90, and use YN = 1.3558N-0.0178, ZN = 1.4488N-0.023. The tooth profile is uncrowned. This is a commercial enclosed gear unit. (a) Find the factor of safety of the gears in bending. (b) Find the factor of safety of the gears in wear. (c) By examining the factors of safety, identify the threat to each gear and to the…arrow_forwardpinion having 20 involute teeth of module pitch 6 mm rotates at 200 r.p.m. and transmits 1.5 kW to a gear wheel having 50 teeth. The addendum on both the wheels is 1/4 of the circular pitch. The angle of obliquity is 20°. Find (a) the length of the path of approach ; (b) the length of the arc of approach; (c) the normal force between the teeth at an instant where there is only pair of teeth in contact.arrow_forward2. A shaft is supported on bearings A and B, 800 mm between centres. A 20 degrees straight tooth spur gear having 600 mm pitch diameter, is located 200 mm to the right of the left hand bearing A, and a 700 mm diameter pulley is mounted 250 mm towards the left of bearing B. The gear is driven by a pinion with a downward tangential force while the pulley drives a horizontal belt having 180 degrees angle of wrap. The pulley also serves as a flywheel and weighs 2000 N. The maximum belt tension is 3000 N and the tension ratio is 3: 1. Determine the maximum bending moment and the necessary shaft diameter if the allowable shear stress of the material is 40 MPa.arrow_forward

- A parallel-shaft gearset consists of an 18-tooth helical pinion driving a 32-tooth gear. The pinion has a left-hand helix angle of 20, a normal pressure angle of 25, and a normal module of 3 mm. Evaluate root diameter (mm) of the pinion. A) 51,21 B) 49,92 C) 50,00 D) 48,00 E) 52,08arrow_forwardA gear-reduction unit uses the countershaft depicted in the figure. Find the two bearing reactions.The bearings are to be angular-contact ball bearings, having a desired life of 60 kh when used at 330 rev/min. Use 1.2 for the application factor and a reliability goal for the bearing pair of 0.92arrow_forwardA truck equipped with a 50 HP engine uses a roller chain as the final drive to the rear axle. The driving sprocket runs at 225 rpm with a center distance of approximately 500 fpm. The transmission efficiency between the engine and the driving sprocket is 85%. 1.1 Determine the pitch and width of chain to be used. 1.2 Determine the number of teeth in each sprocket and the pitch diameters.arrow_forward

- A pickup truck is driving at a speed of 100 km/h on a leveled road. This truck has4 wheels of the same diameter of 400 mm and drives at a gear ratio of 5 to 1 ifits gearbox 5th gear is selected. The gear’s teeth are of involute form with amodule of 8 mm, an addendum is double the module, and the pressure angle isequal to 20° .1.1. If the driving shaft of the front wheels of the truck is connected to the output shaftof the gearbox, determine the number of teeth on the pinion to avoid interferenceand the corresponding number of teeth on the gear wheel.arrow_forwardA pair of gray iron and steel helical gears, having a helix angle of 15° with 20° full-depth teeth are to transmit 10 hp at 1500 rpm of a 4-in pinion having a total number of 28teeth. The velocity ratio desired is about mw = 4. Find the (a) normal circular pitch, (b) normal diametral pitch, (c) axial pitch, and (d) dynamic loadarrow_forwardA pair of helical gears transmit 15 KW power and the pinion is rotating at 1000 rpm. The helix angle is 0.50 radians and the normal pressure angle is 0.35 radians. The pitch diameter of the pinion is 70 mm and the pitch diameter of the gear is 210 mm. Determine the tangential, radial, and axial forces between the gear teeth.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY