Concept explainers

The hub diameter and projection for the gear of Prob. 13–51 are 100 and 37.5 mm, respectively. The face width of the gear is 50 mm. Locate bearings C and D on opposite sides, spacing C 10 mm from the gear on the hidden face (see figure) and D 10 mm from the hub face. Choose one as the thrust bearing, so that the axial load in the shaft is in compression. Find the output torque and the magnitudes and directions of the forces exerted by the bearings on the gearshaft.

The output torque.

The force exerted by the bearing

The force by the bearing

Answer to Problem 52P

The output torque is

The force exerted by the bearing

The force by the bearing

Explanation of Solution

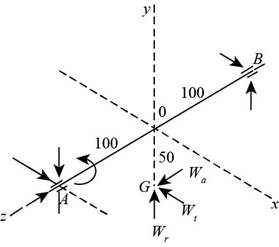

The figure below shows the forces acting at the centre of the gear

Figure-(1)

The tangential load on the centre of the gear is

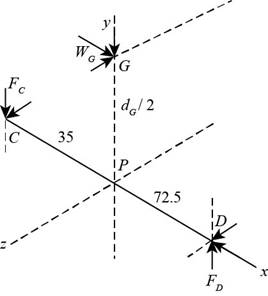

The figure below shows the forces on the bearing

Figure-(2)

Write the expression for the linear velocity of the worm.

Here, the pitch diameter of the worm is

Write the expression for the tangential load on the gear.

Here, the power is

Write the expression for lead.

Here, the number of threads on worm is

Write the expression for the lead angle.

Write the expression for the force exerted by the by the gear on the worm.

Here, the normal pressure angle is

Write the expression for the sliding velocity.

Write the expression for the load in the y direction.

Write the expression for the load in the z direction.

Write the expression for vector form of the force against the worm.

The force on the gear will be equal but opposite to the force against the worm.

Write the expression for vector form of the force against the gear.

Write the diameter of the gear.

Here, the number of teeth on the gear is

The axial pitch and the transverse pitch is same hence

Write the position vector of

Here, the distance between the points

Write the position vector of

Here, the distance between the points

Write the moment equation at

Here, the force vector at

Write the expression for the force vector at

Here, the force in x-direction is

Write the force balance equation for the bearing

Conclusion:

Substitute

Substitute

Substitute

Substitute

Substitute

Convert the units of sliding velocity from

Refer to Figure 13-42 “Representative values of the coefficient of friction for worm gearing.” to obtain the friction coefficient as 0.043 with respect to sliding velocity as

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Solve Equation (XVII) for

Thus, the output torque is

Solve Equation (XVII) for

Solve Equation (XVII) for

Substitute

Thus, the force exerted by the bearing

Substitute

Thus, the force by the bearing

Want to see more full solutions like this?

Chapter 13 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- The motor shown in the figure supplies 16.5 kW at 1540 rpm at A. Shafts (1) and (2) are each solid 28 mm diameter shafts. Shaft (1) is made of an aluminum alloy [ G=26 GPa], and shaft (2) is made of bronze [ G=45 GPa]. The shaft lengths are L1=3.3m and L2=2.9m, respectively. Gear B has 56 teeth, and gear C has 97 teeth. The bearings shown permit free rotation of the shafts. Determine: the rotation angle of gear D with respect to flange A. [Answer φD/A = 0.314 rad]arrow_forwardpower (N)=9.9kw Input speed (n1)=2350rpm Distance between centers (a)=168mm Total distance between Ave B bearings=440mm module(m)=3mm question 3 Calculate the power on the output shaft since there is 3% loss in gears in gearboxes, rolling bearings in support bearings (2% loss in a pair of bearings) and sealing element spring seal (4% loss in a pair of sealing elements).arrow_forwardA solid constant-diameter circular shaft is subjected to torques TA = 420 lb- ft, TB = 1,040 lb- ft, TC = 850 lb-ft, andTD = 230 lb-ft, acting in the directions shown in the figure. The bearings shown allow the shaft to turn freely. (a) Plot a torque diagram showing the internal torque in segments (1), (2), and (3) of the shaft. Use the right-hand rule. (b) If the allowable shear stress in the shaft is 6,000 psi, what is the minimum acceptable diameter for the shaft?arrow_forward

- Assume that the gear keyed to the shaft shown in the figure below is a Class 50, cast iron flywheel of 15-inin outside diameter and 1-in thickness. The hub is 4-in dia and 3-in thick. The shaft is steel. Determine the critical frequency of shaft whirl for the assembly shown using the following dimensions: a = 4 in , b = 12 in , l = 14 in , the shaft diameter is 2 in. Assume the following: The applied transverse force PP and the Torque TT to be zero. The mass of the steel shaft can be ignored.arrow_forwarda) A line shaft as shown in Figure Q is driven using a motor placed vertically below it. The pulley on the line shaft is 1.6 m in diameter and has belt tensions 7.5 kN and 2.4 kN on the tight side and slack side of the belt respectively. Both tensions may be assumed to be vertical and the weight of the pulley is negligible. If the pulley is overhang from the shaft, the distance of the centre line of the pulley from the centre line of the bearing being 500 mm.6.Figure Q(i) Predict using distortion energy theory, the appropriate diameter of the shaft that failure will not occur if the yield strength, Sy = 370 Mpa and factor of safety is 2.5. (ii) Assuming the maximum allowable shear stress of 42 MPa, find its diameter using maximum shear stress theory. (iii) Comparing the diameters in (i) and (iii) above, which of them would you have used to design your shaft and why?arrow_forwardA compound shaft drives three gears, as shown. Segments (1) and (2) of the compound shaft are hollow bronze [G = 6,500 ksi] tubes, which have an outside diameter of 2.40 in. and a wall thickness of 0.1375 in. Segments (3) and (4) are solid 1.00-in.-diameter steel [G = 11,500 ksi] shafts. The shaft lengths are L1 = 58 in., L2 = 16 in., L3 = 16 in., and L4 = 28 in. The torques applied to the shafts have magnitudes of TB = 970 lb·ft, TD = 430 lb·ft, and TE = 170 lb·ft, acting in the directions shown. The bearings shown allow the shaft to turn freely. Using the sign convention presented in Section 6.6., calculate: (a) the magnitude of the maximum shear stress in the compound shaft. (b) the rotation angle of flange C with respect to flange A. (c) the rotation angle of gear E with respect to flange A.arrow_forward

- A compound shaft drives three gears, as shown in FigureP6.14. Segments (1) and (2) of the shaft are hollow bronze [G =6,500 ksi] tubes with an outside diameter of 1.75 in. and a wallthickness of 0.1875 in. Segments (3) and (4) are solid 1.00 in. diametersteel [G = 11,500 ksi] shafts. The shaft lengths are L1 = 60 in.,L2 = 14 in., L3 = 20 in., and L4 = 26 in. The torques applied to theshafts have magnitudes TB = 960 lb ⋅ ft, TD = 450 lb ⋅ ft, and TE =130 lb ⋅ ft, acting in the directions shown. The bearings shown allowthe shaft to turn freely. Calculate(a) the maximum shear stress in the compound shaft.(b) the rotation angle of flange C with respect to flange A.(c) the rotation angle of gear E with respect to flange A.arrow_forwardShaft a in the figure has a power input of 75 kW at a speed of 1000 rev/min in the counterclockwise direction. The gears have a module of 5 mm and a 20° pressure angle. Gear 3 is an idler (b) Find the torque T4c that gear 4 exerts on shaft c.arrow_forwardA rack and pinion is a pair of gears that converts rotational motion into translation. As shown in the figure, a torque τ is applied to the shaft. The pinion rotates and causes the rack to translate. The mass moment of inertia of the pinion is I and the mass of the rack is m. Draw the free-body diagram and derive the differential equation of motionarrow_forward

- A gear train is composed of four helical gears with the three shaft axes in a single plane, as shown in the figure. The gears have a normal pressure angle of 20 and a 30 helix angle. Gear is the driver, and is rotating counterclockwise as viewed from the top. Shaft b is an idler and the transmitted load from gear 2 to gear 3 is 500 Ibf. The gears on shaft b both have a normal diametral pitch of 7 teeth/in and have 54 and 14 teeth, respectively. Find the forces exerted by gears 3 and 4 on shaft barrow_forwardIn the gear system shown in the figure, the motor applies a torque of 231 N-m to the gear at A. A torque of TC = 440 N-m is removed from the shaft at gear C, and the remaining torque is removed at gear D. Segments (1) and (2) are solid 38-mm-diameter steel (G = 80 GPa) shafts, and the bearings shown allow free rotation of the shaft. Assume DA = 110 mm, DB = 370 mm, L1 = 1.7 m, and L2 = 1.1 m. Calculate the rotation angle of gear D relative to gear B. Express your answer in radian rounded to the nearest thousandths.arrow_forwardA gear train is composed of four helical gears with the tree shaft axes in a single plane, as shown in the figure. The gears have a normal pressure angle of 20° and a 30°helix angle. Gear 2 is the driver, and is rotating counterclockwise as viewed from the top. Shaft b is and idler and the transmitted load from gear 2 to gear 3 is 500 lbf. The gears on shaft b both have a normal diametral pitch of 7 teeth/in and have 54 and 14 teeth, respectively. Find the forces exerted by gears 3 and 4 on shaft b.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY