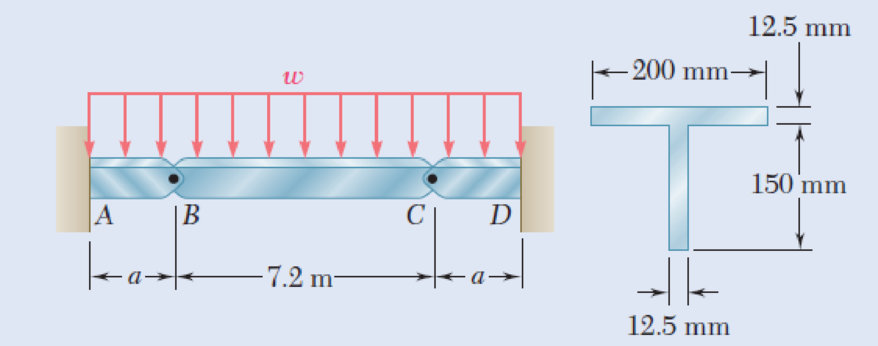

Beams AB, BC, and CD have the cross section shown and are pin-connected at B and C. Knowing that the allowable normal stress is +110 MPa in tension and –150 MPa in compression, determine (a) the largest permissible value of w if beam BC is not to be overstressed, (b) the corresponding maximum distance a for which the cantilever beams AB and CD are not overstressed.

Fig. P5.89

(a)

The largest permissible value of w for the condition that the beam BC is not overstressed.

Answer to Problem 89P

The largest permissible value of w is

Explanation of Solution

Given information:

The allowable normal stress of the material in tension is

The allowable normal stress of the material in compression is

Calculation:

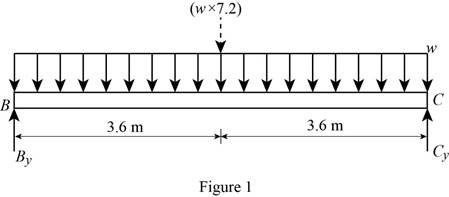

Show the free-body diagram of the section BC as in Figure 1.

Determine the vertical reaction at point C by taking moment about point B.

Determine the vertical reaction at point B by resolving the vertical component of forces.

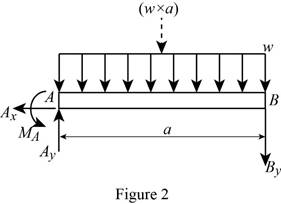

Show the free-body diagram of the section AB as in Figure 2.

Determine the vertical reaction at point A by resolving the vertical component of forces.

Determine the moment at point A by taking moment about the point A.

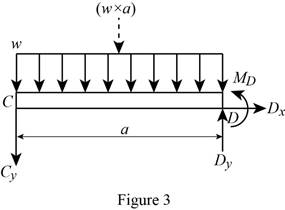

Show the free-body diagram of the section CD as in Figure 3.

Determine the vertical reaction at point D by resolving the vertical component of forces.

Determine the moment at point D by taking moment about the point D.

Shear force:

Show the calculation of shear force as follows;

Show the calculated shear force values as in Table 1.

| Location (x) m | Shear force (V) kN |

| A | |

| B | 3.6w |

| C | –3.6w |

| D |

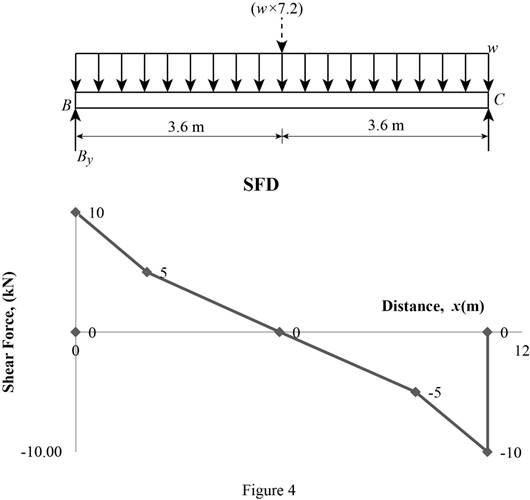

Plot the shear force diagram as in Figure 4.

Location of the maximum bending moment:

The maximum bending moment occurs where the shear force changes sign.

Refer to Figure 4;

Use the similar triangle concept.

The maximum bending moment occurs at a distance of

Bending moment:

Show the calculation of the bending moment as follows;

Show the calculated bending moment values as in Table 2.

| Location (x) m | Bending moment (M) kN-m |

| A | |

| B | 0 |

| Max BM | 6.48w |

| C | 0 |

| D |

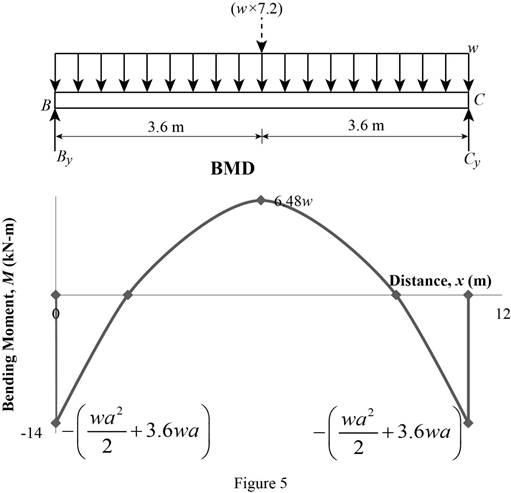

Plot the bending moment diagram as in Figure 5.

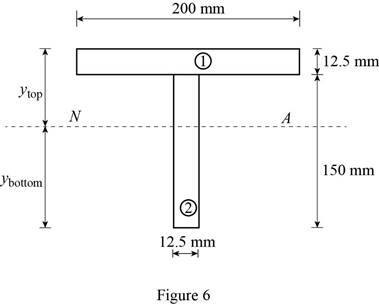

Show the free-body diagram of the T-section as in Figure 6.

Determine the centroid in y-axis

Here, the area of the section 1 is

Refer to Figure 4;

Substitute

Determine the moment of inertia (I) using the equation.

Here, the depth of the section 1 is

Substitute 12.5 mm for

Refer to Figure 4;

Tension at Points B and D:

Refer to Figure 5;

Determine the moment at points B and D using the relation.

Substitute 110 MPa for

Compression at Points B and C:

Refer to Figure 5;

Determine the moment at points B and D using the relation.

Substitute –150 MPa for

Tension at maximum bending moment:

Refer to Figure 5;

Determine the maximum moment using the relation.

Substitute 110 MPa for

Compression at maximum bending moment:

Refer to Figure 5;

Determine the maximum moment using the relation.

Substitute –150 MPa for

Refer to the calculated distribution loads; the smallest value controls the design.

Refer to Figure 5;

Equate the maximum bending moment calculated and the maximum bending moment in the tension side.

Therefore, the largest permissible value of w for the condition that the beam BC is not overstressed is

(b)

The maximum distance a for the condition that the beams AB and CD are not overstressed.

Answer to Problem 89P

The maximum distance a for the condition that the beams AB and CD are not overstressed is

Explanation of Solution

Refer to Part (a), Figure 4;

The maximum bending moment in the beams AB and CD occurs at the ends A and D.

The calculated maximum bending moment at the points A and D is as follows:

The maximum allowable compression moment at the points A and D is as follows:

Equate the values;

Refer to the answer of the part (a);

Substitute

Therefore, the maximum distance a for the condition that the beams AB and CD are not overstressed is

Want to see more full solutions like this?

Chapter 5 Solutions

Mechanics of Materials, 7th Edition

- For the beam with the cross-section shown, given that: V= 100 N b= 20 cm h=20 cm The max shear stress equals:arrow_forwardThe center span of the Verrazano-Narrows Bridge consists of two uniform roadways suspended from four cables. The design of the bridge allows for the effect of extreme temperature changes that cause the sag of the center span to vary from hw= 386 ft in winter to hs= 394 ft in summer. Knowing that the span is L = 4260 ft, determine the change in length of the cables due to extreme temperature changes.arrow_forwardA weightlifting bar is loaded symmetrically in A and D (P = 1500N of each side). The weightlifter's hands are located at B and C, 0.45 m from A and D. Determine the maximum bending moment in the bar ABCD and the minimum diameter d of the bar knowing that the constraint admissible for the material of the bar is 200MPa.arrow_forward

- For the wide-flange beam with the loading shown, determine the largest load P that can be applied, knowing that the maximum normal stress is 160 MPa and the largest shearing stress is 100 MPa. W360 x 122 Barrow_forwardDetermine (a) the distance a for which the maximum absolute value of the bending moment in the beam is as small as possible, (b) the corresponding maximum normal stress due to bending.arrow_forwardKnowing that the bending moment in the reinforced concrete beam is 1100 kip?ft and that the modulus of elasticity is 3.625 *106 psi for the concrete and 29* 106 psi for the steel, determine (a) the stress in the steel, (b) the maximum stress in the concretearrow_forward

- Two small channel sections DF and EH have been welded to the uniform beam AB of weight W = 3 kN to form the rigid structural member shown. This member is being lifted by two cables attached at D and E . Knowing that 0= 30° and neglecting the weight of the channel sections, (a) draw the shear and bending-moment diagrams for beam AB, (b) determine the maximum absolute values of the shear and bending moment in the beam.arrow_forwardA steel bar and an aluminum bar are bonded together to form the composite beam shown. The modulus of elasticity for aluminum is 70 GPa and for steel is 200 GPa. Knowing that the beam is bent about a horizontal axis by a couple of moment M= 1500 N·m, determine the maximum stress in (a) the aluminum, (b) the steel.arrow_forwardDraw the shearing-force and bending-moment diagrams for the following beams: A cantilever of length 20 m carrying a load of 10 kN at a distance of 15 m from the supported end. A cantilever of length 20 m carrying a load of 10 kN uniformly distributed over the inner 15 m of its length. A cantilever of length 12 m carrying a load of 8 kN, applied 5 m from the supported end, and a load of 2kN/m over its whole length.arrow_forward

- Determine (a) the distance a for which the absolute value of the bending moment in the beam is as small as possible, (b) the corresponding moximum normal stress due to bending.arrow_forwardA steel pipe and an aluminum pipe are securely bonded together to form the composite beam shown. The modulus of elasticity is 200 GPa for the steel and 70 GPa for the aluminum. Knowing that the composite beam is bent by a couple of moment 500 N?m, determine the maximum stress (a) in the aluminum, (b) in the steel.arrow_forwardLink AB, of width b = 50 mm and thickness t = 6 mm, is used to support the end of a horizontal beam. Knowing that the average normal stress in the link is –140 MPa, and that the average shearing stress in each of the two pins is 80 MPa, determine (a) the diameter d of the pins, (b) the average bearing stress in the link.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY