a)

To determine: The graph illustrating the three total cost lines on the same chart.

a)

Answer to Problem 6P

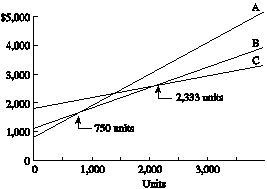

Graph illustrating the three cost lines:

Explanation of Solution

Given information:

Refurbishing cost = $800

Cost of making modifications = $1,100

Purchase of new equipment = $1,800

Refurbishing labor and material costs = $1.10 / board

Modifications labor and material costs = $0.70 / board

New equipment variable costs = $0.40 / board

Formation of cost lines denoted in the graph:

The cost line is formed by multiplying the labor cost and number of units and summing the value with the

Refurbishing cost line (A):

The cost line (A) mentioned in the graph is derived as follows:

Modifications cost line (B):

The cost line (B) mentioned in the graph is derived as follows:

New equipment cost line (C):

The cost line (C) mentioned in the graph is derived as follows:

Calculation of cost at 0 units and arbitrary units of 4,000 using the cost lines (A), (B) and (C):

Refurbishing:

At 0 units:

At 4,000 units:

Modification:

At 0 units:

At 4,000 units:

New equipment:

At 0 units:

At 4,000 units:

The cost values at 0 and 400 units are plotted on the graph.

b)

To determine: The alternative to choose when SB company thinks it can sell more than 3,000 boards.

b)

Answer to Problem 6P

The best alternative when more than 3,000 boards can be sold is alternative 1.

Explanation of Solution

Given information:

Refurbishing cost = $800

Cost of making modifications = $1,100

Purchase of new equipment = $1,800

Refurbishing labor and material costs = $1.10 / board

Modifications labor and material costs = $0.70 / board

New equipment variable costs = $0.40 / board

Formation of cost lines:

The cost line is formed by multiplying the labor cost and number of units and summing the value with the process cost. Let ‘Y’ denote the cost line. Let ‘x’ denote the number of units.

Refurbishing cost line:

Modifications cost line:

New equipment cost line:

Calculation of cost at 3,000 boards:

Alternative 1:

Alternative 1 is refurbishing cost calculated by using equation (A)

Alternative 2:

Alternative 2 is modifications cost calculated by using equation (B)

Alternative 3:

Alternative 3 is new equipment cost calculated by using equation (C)

The total cost of alternative 1 is less than alternative 2 and 3 (3000 < 4100, 3200).

Hence, the best alternative for making 3,000 boards is alternative 3.

c)

To determine: The alternative to choose when SB company thinks that the market for boards will be between 1,000 and 2,000 boards.

c)

Answer to Problem 6P

The best alternative when the market for boards will be between 1,000 and 2,000 boards is making modifications.

Explanation of Solution

Given information:

Refurbishing cost = $800

Cost of making modifications = $1,100

Purchase of new equipment = $1,800

Refurbishing labor and material costs = $1.10 / board

Modifications labor and material costs = $0.70 / board

New equipment variable costs = $0.40 / board

Formation of cost lines:

The cost line is formed by multiplying the labor cost and number of units and summing the value with the process cost. Let ‘Y’ denote the cost line. Let ‘x’ denote the number of units.

Refurbishing cost line:

Modifications cost line:

New equipment cost line:

Calculation of best alternative:

The best alternative is calculated by equating (A) with (B) and (B) with (C).

Calculation of lower limit value:

Lower limit value is calculated by Equating (A) with (B):

Calculation of Upper limit value:

Upper limit value is calculated by Equating (B) with (C):

The boards must be in the range of 1,000 to 2,000. Hence, the best alternative is making major modifications.

Want to see more full solutions like this?

Chapter 7 Solutions

Principles Of Operations Management

- Tribal Systems, Inc., is opening a new plant and has yet todecide on the type of process to employ. A labor-intensiveprocess would cost $10,000 for tools and equipment and $14 for labor and materials per item produced. A more au-tomated process costs $50,000 in plant and equipment but has a labor/material cost of $8 per item produced. A fullyautomated process costs $300,000 for plant and equipmentand $2 per item produced. If process selection were basedsolely on lowest cost, for what range of production wouldeach process be chosen?arrow_forwardProduct X currently sells for $12 per unit. The variable costs is $4 per unit and 10,000 units are sold annually with a profit of $30,000 per year. A new design will increase the variable cost by 24% and fixed cost by 13% but sales will increase to 13974 units per year. At what selling price do the break even occurs for the new design?arrow_forwardBecause of the coronavirus, Cafes and restaurants are going to be open between 8 a.m. and 20 p.m. , and with 50% capacity. Imagine that the Ministry of Health thinks Coronavirus can last for years and wants to develop a system that can be used to fulfill the above rule. Write a report about that... 1- Write a “problem definition”, “objectives” and “issues to be solved” for this rule, as a system analyst you are. 2- What system development methodology do you use and why?arrow_forward

- Good morning Bartleby. I have a research assignment that I am busy with regarding Reliability and maintainability of an ASSET. I decided to create a tangible asset for the community, A Solar Power charging Station. A solar power charging station for the neighborhood grid makes up the assets we I have selected to work on. Solar panels, batteries, distribution lines, and a control system make up the charging station. To reduce potential failures, i have concentrated on making sure the charging station's design achieves reliability and maintainability. So I need Bartleby to assist me with the following aspects for my ASSET: I need to... a)Explain how reliability and maintainability can be achieved in the design of the asset.b) Illustrate the possible failures that could occur due to human error. Explain how would one would consider the different elements of maintainability to minimize such errors.c) consider the different elements of maintainability to improve the reliability of the…arrow_forwarda. distinguish between systems design and systems quality. what challenges are there? b. describe the relationship between design capacity, system capacity, and actual output. how can you ensure a projected output is within the boundaries of the design capacity and system capacity?arrow_forwardMatthew Bailey, as manager of Designs by Bailey,is upgrading his CAD software. The high-performance (HP)software rents for $3,000 per month per workstation. Thestandard-performance (SP) software rents for $2,000 per monthper workstation. The productivity figures that he has availablesuggest that the HP software is faster for his kind of design.Therefore, with the HP software he will need five engineers and with the SP software he will need six. This translates into a vari-able cost of $200 per drawing for the HP system and $240 per drawing for the SP system. At his projected volume of 80 draw-ings per month, which system should he rent?arrow_forward

- Should a GC issue a purchase order or a subcontract agreement for each of the following different concrete scopes: Group of answer choices -Form purchase = -Form rental = -Rebar supply = -Rebar installation = -Concrete pump = -Concrete purchase = -Slab finishing = -Tilt-up crane = answer choices include : -Subcontract, -Purchase Order -Purchase order without Operator/ Subcontract with Operator -Either, subcontract agreement is better due to insurancearrow_forwardThe definition of a system model, and what it is. In developing elementary versions of a product, what considerations must be made?arrow_forwardProduct A has a fixed cost of $5,000 and a variable cost of $5 per unit, it can sell for $20 per unit. Product B has a fixed cost of $8,000 and a variable cost of $9 per unit, it can sell for $30 per unit. Company plans to produce 381 units of either A or B. Which product should be produced?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,