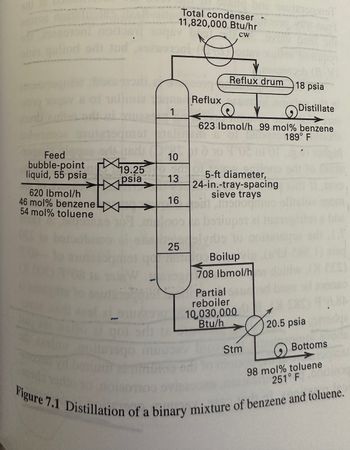

Feed bubble-point liquid, 55 psia 620 lbmol/h 46 mol% benzene 54 mol% toluene 19.25 psia 1 87 190 Total condenser 11,820,000 Btu/hr CW Ө DEB Reflux Reflux 1 10 13 16 25 Reflux drum Distillate 623 lbmol/h 99 mol% benzene 189⁰ F 5-ft diameter, 24-in.-tray-spacing sieve trays Boilup 708 lbmol/h Partial reboiler 10,030,000 Btu/h 18 psia Stm Ø20.5 psia (ES) 7. Bottoms Figure 7.1 Distillation of a binary mixture of benzene and toluene. 98 mol% toluene 251° F

Feed bubble-point liquid, 55 psia 620 lbmol/h 46 mol% benzene 54 mol% toluene 19.25 psia 1 87 190 Total condenser 11,820,000 Btu/hr CW Ө DEB Reflux Reflux 1 10 13 16 25 Reflux drum Distillate 623 lbmol/h 99 mol% benzene 189⁰ F 5-ft diameter, 24-in.-tray-spacing sieve trays Boilup 708 lbmol/h Partial reboiler 10,030,000 Btu/h 18 psia Stm Ø20.5 psia (ES) 7. Bottoms Figure 7.1 Distillation of a binary mixture of benzene and toluene. 98 mol% toluene 251° F

Oh no! Our experts couldn't answer your question.

Don't worry! We won't leave you hanging. Plus, we're giving you back one question for the inconvenience.

Submit your question and receive a step-by-step explanation from our experts in as fast as 30 minutes.

You have no more questions left.

Message from our expert:

Our experts are unable to provide you with a solution at this time. Try rewording your question, and make sure to submit one question at a time. We've credited a question to your account.

Your Question:

What are the mass flow (kg/hour) and approximate volumetric flow (L/hour) of the process in fig 7.1? Assuming throughput scales linearly with column cross-sectional area, what would these numbers be for a column 30 feet in diameter? What is the reboiler duty of the Fig. 7.1 column in watts, and in horsepower? How does this compare with the electrical power consumption of a typical American home? Sketch the two operating lines and the feed q line for the process of Fig. 7.1. ATTACHED

Transcribed Image Text:Feed

bubble-point

liquid, 55 psia

620 lbmol/h

46 mol% benzene

54 mol% toluene

19.25

psia

1

87

190

Total condenser

11,820,000 Btu/hr

CW

Ө

DEB Reflux

Reflux

1

10

13

16

25

Reflux drum

Distillate

623 lbmol/h 99 mol% benzene

189⁰ F

5-ft diameter,

24-in.-tray-spacing

sieve trays

Boilup

708 lbmol/h

Partial

reboiler

10,030,000

Btu/h

18 psia

Stm

Ø20.5 psia

(ES)

7.

Bottoms

Figure 7.1 Distillation of a binary mixture of benzene and toluene.

98 mol% toluene

251° F

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The