1. Prepare a customer profitability analysis for Trace Telecom and Caltex Computer. (Hint: Refer to Exhibit 5-13 for guidance.) 2. Build a spreadsheet: Construct an Excel spreadsheet to solve requirement (1) above. Show how the solution will change if the following information changes: Trace Telecom's sales revenue was S185,000 and Caltex Computer's cost of goods sold was $59,000.

1. Prepare a customer profitability analysis for Trace Telecom and Caltex Computer. (Hint: Refer to Exhibit 5-13 for guidance.) 2. Build a spreadsheet: Construct an Excel spreadsheet to solve requirement (1) above. Show how the solution will change if the following information changes: Trace Telecom's sales revenue was S185,000 and Caltex Computer's cost of goods sold was $59,000.

Survey of Accounting (Accounting I)

8th Edition

ISBN:9781305961883

Author:Carl Warren

Publisher:Carl Warren

Chapter10: Accounting Systems For Manufacturing Operations

Section: Chapter Questions

Problem 10.25E: Activity-based costing in an insurance company Umbrella Insurance Company carries three major lines...

Related questions

Question

100%

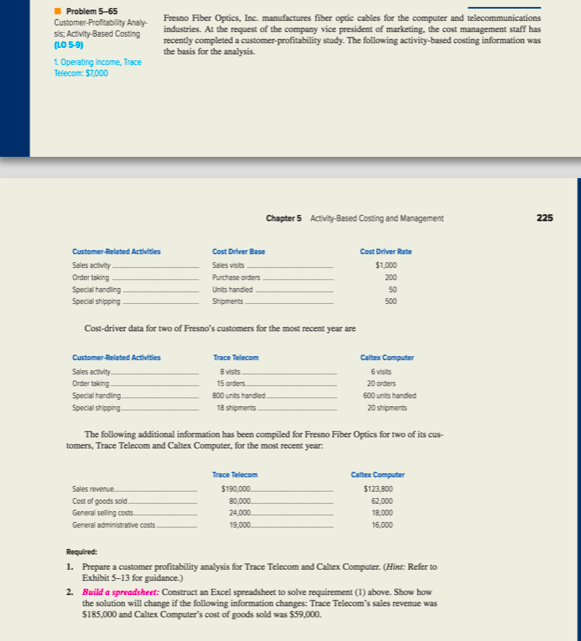

Transcribed Image Text:I Problem 5-65

Customer-Profitability Analy-

sis, Activity-Based Costing

(LO 5-9)

Fresno Fiber Optics, Inc. manufactures fiber optic cables for the computer and telecommunications

industries. At the request of the company vice president of marketing, the cost management staff has

recently completed a customer-profitability study. The following activity-based costing information was

the basis for the analysis.

1. Operating income, Trace

Telecom: $7,000

Chapter 5 ActivtyBased Costing and Management

225

Customer-Related Activities

Cost Driver Base

Cost Driver Rate

Sales activity

Sales visits

$1,000

Order taking

Purchese orders

200

Units handied.

Special handing -

Special shipping

50

Shipments

500

Cost-driver data for two of Fresno's customers for the most recent year are

Customer-Related Activities

Trace Telecom

Caltex Computer

8 visits

6 vists

Sales activity.

Order taking

15 orders

20 orders

Special handing.

800 units handled.

600 unts handled

Special shipping

18 shipments

20 shipments

The following additional information has been compiled for Fresno Fiber Optics for two of its cus-

tomers, Trace Telecom and Caltex Computer, for the most recent year:

Trace Telecom

Caltex Computer

Sales revenue.

$190,000.

$123,800

Cost of goods soid.

General seling costs

80,000.

62.000

24,000.

18,000

General administrative costs

19,000.

16,000

Required:

1. Prepare a customer profitability analysis for Trace Telecom and Caltex Computer. (Hint: Refer to

Exhibit 5-13 for guidance.)

2. Build a spreadsheet: Construct an Excel spreadsheet to solve requirement (1) above. Show how

the solution will change if the following information changes: Trace Telecom's sales revenue was

S185,000 and Caltex Computer's cost of goods sold was S59,000.

Transcribed Image Text:Problem 5-63

Better Bagels, Inc. manufactures a variety of bagels, which are frozen and sold in grocery stores. The Basic Elements of a Produc-

production process consists of the following steps.

tion Process; Non-Value-

1. Ingredients, such as flour and raisins, are received and inspected. Then they are stored until needed. Added Costs

(LO 5-7, 5-8, 5-10)

2. Ingredients are carried on hand carts to the mixing room.

3. Dough is mixed in 40-pound batches in four heavy-duty mixers.

4. Dough is stored on large boards in the mixing room until a bagel machine is free.

5. A board of dough is carried into the bagel room. The board is tipped, and the dough slides into

the hopper of a bagel machine. This machine pulls off a small piece of dough, rolls it into a cylin-

drical shape, and then squeezes it into a doughnut shape. The bagel machines can be adjusted

in a setup procedure to accommodate different sizes and styles of bagels. Workers remove the

uncooked bagels and place them on a tray, where they are kept until a boiling vat is free.

6. Next the trays of uncooked bagels are carried into an adjoining room, which houses three

50-gallon vats of boiling water. The bagels are boiled for approximately one minute.

7. Bagels are removed from the vats with a long-handled strainer and placed on a wooden board.

The boards full of bagels are carried to the oven room, where they are kept until an oven rack is

free. The two ovens contain eight racks which rotate but remain upright, much like the seats on a

Ferris wheel. A rack full of bagels is finished baking after one complete revolution in the oven.

When a rack full of bagels is removed from the oven, a fresh rack replaces it. The oven door is

opened and closed as each rack completes a revolution in the oven.

8. After the bagels are removed from the oven, they are placed in baskets for cooling.

9. While the bagels are cooling, they are inspected. Misshapen bagels are removed and set aside.

(Most are eaten by the staff.)

10. After the bagels are cool, the wire baskets are carried to the packaging department. Here the

bagels are dumped into the hopper on a bagging machine. This machine packages a half-dozen

bagels in each bag and seals the bag with a twist tie.

11. Then the packaged bagels are placed in cardboard boxes, each holding 24 bags. The boxes are placed

on a forklift and are driven to the freezer, where the bagels are frozen and stored for shipment.

Required:

1. Identify the steps in the bagel-production process that fall into each of the following categories:

process time, inspection time, move time, waiting time, storage time.

2. List the steps in the production process that could be candidates for non-value-added activities.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Survey of Accounting (Accounting I)

Accounting

ISBN:

9781305961883

Author:

Carl Warren

Publisher:

Cengage Learning

Financial & Managerial Accounting

Accounting

ISBN:

9781337119207

Author:

Carl Warren, James M. Reeve, Jonathan Duchac

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Survey of Accounting (Accounting I)

Accounting

ISBN:

9781305961883

Author:

Carl Warren

Publisher:

Cengage Learning

Financial & Managerial Accounting

Accounting

ISBN:

9781337119207

Author:

Carl Warren, James M. Reeve, Jonathan Duchac

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Accounting Information Systems

Finance

ISBN:

9781337552127

Author:

Ulric J. Gelinas, Richard B. Dull, Patrick Wheeler, Mary Callahan Hill

Publisher:

Cengage Learning