1. The sum of the sphere volumes of all atoms within a unit cell (assuming the atomic hard sphere model) divided by the unit cell volume. 2. The instantaneous load divided by the original area perpendicular to the direction of the load. 3. The amount of deformation divided by the original length of the material.

1. The sum of the sphere volumes of all atoms within a unit cell (assuming the atomic hard sphere model) divided by the unit cell volume. 2. The instantaneous load divided by the original area perpendicular to the direction of the load. 3. The amount of deformation divided by the original length of the material.

Welding: Principles and Applications (MindTap Course List)

8th Edition

ISBN:9781305494695

Author:Larry Jeffus

Publisher:Larry Jeffus

Chapter26: Welding Metallurgy

Section: Chapter Questions

Problem 3R: What are the basic units of measure for heat?

Related questions

Question

dont have to explain just identify them

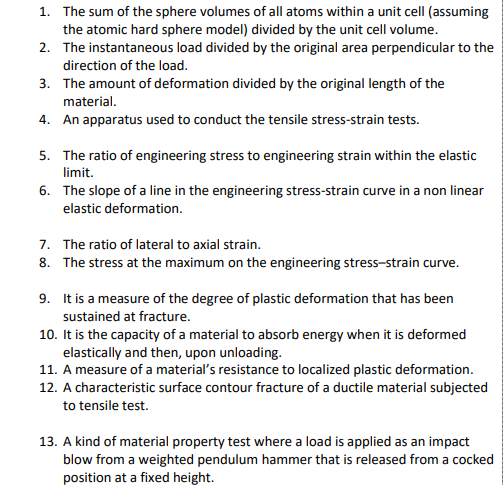

Transcribed Image Text:1. The sum of the sphere volumes of all atoms within a unit cell (assuming

the atomic hard sphere model) divided by the unit cell volume.

2. The instantaneous load divided by the original area perpendicular to the

direction of the load.

3. The amount of deformation divided by the original length of the

material.

4. An apparatus used to conduct the tensile stress-strain tests.

5. The ratio of engineering stress to engineering strain within the elastic

limit.

6.

The slope of a line in the engineering stress-strain curve in a non linear

elastic deformation.

7. The ratio of lateral to axial strain.

8. The stress at the maximum on the engineering stress-strain curve.

9.

It is a measure of the degree of plastic deformation that has been

sustained at fracture.

10. It is the capacity of a material to absorb energy when it is deformed

elastically and then, upon unloading.

11. A measure of a material's resistance to localized plastic deformation.

12. A characteristic surface contour fracture of a ductile material subjected

to tensile test.

13. A kind of material property test where a load is applied as an impact

blow from a weighted pendulum hammer that is released from a cocked

position at a fixed height.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning