1. What is a balanced process? How do you scale a flowchart? What is a basis of calculation? 2. The processes shown below were balanced using the indicate bases of calculation. Scale as directed, and draw flowcharts for the scaled processes. (a) Mix C₂H6 with air. Basis of calculation: 100 mol C₂H6. 100 mol C₂H6 2000 mol air 0.21 mol O₂/mol 0.79 mol N₂/mol Scale up to a feed of 1000 kmol C₂H6/h. 2100 mol 0.0476 mol C₂He/mol 0.200 mol O₂/mol 0.752 mol N₂/mol

1. What is a balanced process? How do you scale a flowchart? What is a basis of calculation? 2. The processes shown below were balanced using the indicate bases of calculation. Scale as directed, and draw flowcharts for the scaled processes. (a) Mix C₂H6 with air. Basis of calculation: 100 mol C₂H6. 100 mol C₂H6 2000 mol air 0.21 mol O₂/mol 0.79 mol N₂/mol Scale up to a feed of 1000 kmol C₂H6/h. 2100 mol 0.0476 mol C₂He/mol 0.200 mol O₂/mol 0.752 mol N₂/mol

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

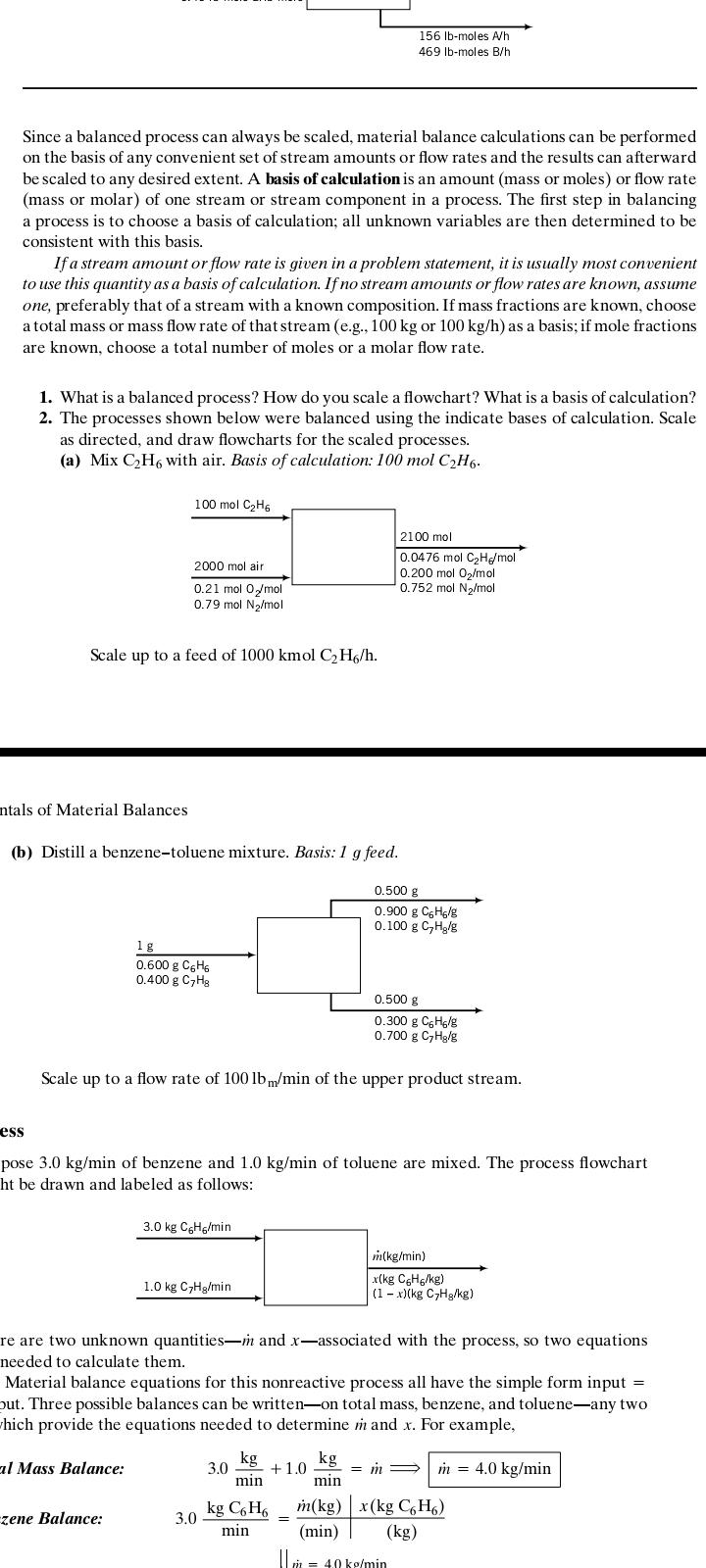

Transcribed Image Text:Since a balanced process can always be scaled, material balance calculations can be performed

on the basis of any convenient set of stream amounts or flow rates and the results can afterward

be scaled to any desired extent. A basis of calculation is an amount (mass or moles) or flow rate

(mass or molar) of one stream or stream component in a process. The first step in balancing

a process is to choose a basis of calculation; all unknown variables are then determined to be

consistent with this basis.

If a stream amount or flow rate is given in a problem statement, it is usually most convenient

to use this quantity as a basis of calculation. If no stream amounts or flow rates are known, assume

one, preferably that of a stream with a known composition. If mass fractions are known, choose

a total mass or mass flow rate of that stream (e.g., 100 kg or 100 kg/h) as a basis; if mole fractions

are known, choose a total number of moles or a molar flow rate.

1. What is a balanced process? How do you scale a flowchart? What is a basis of calculation?

2. The processes shown below were balanced using the indicate bases of calculation. Scale

as directed, and draw flowcharts for the scaled processes.

(a) Mix C₂H6 with air. Basis of calculation: 100 mol C₂H6.

ntals of Material Balances

Scale up to a feed of 1000 kmol C₂H6/h.

100 mol C₂H6

2000 mol air

0.21 mol O₂/mol

0.79 mol N₂/mol

(b) Distill a benzene-toluene mixture. Basis: 1 g feed.

1g

0.600 g C₂H₂

0.400 g C₂H₂

al Mass Balance:

zene Balance:

0.500 g

0.300 g C6H6/g

0.700 g C₂Hg/g

Scale up to a flow rate of 100 lbm/min of the upper product stream.

ess

pose 3.0 kg/min of benzene and 1.0 kg/min of toluene are mixed. The process flowchart

ht be drawn and labeled as follows:

3.0 kg C6H6/min

1.0 kg C7Hg/min

re are two unknown quantities-m and x-associated with the process, so two equations

needed to calculate them.

3.0

156 lb-moles A/h

469 lb-moles B/h.

Material balance equations for this nonreactive process all have the simple form input =

put. Three possible balances can be written on total mass, benzene, and toluene-any two

which provide the equations needed to determine m and x. For example,

3.0

kg

min

+1.0

kg C6H6

min

2100 mol

0.0476 mol C₂Hg/mol

0.200 mol O₂/mol

0.752 mol N₂/mol

0.500 g

0.900 g C6H6/g

0.100 g C₂H₂/g

=

kg

min

m(kg/min)

x(kg C6H6/kg)

(1-x)(kg C7Hg/kg)

= m => in = 4.0 kg/min

11m m 40 kg/min

=

m(kg) x(kg C6H6)

(min)

(kg)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The