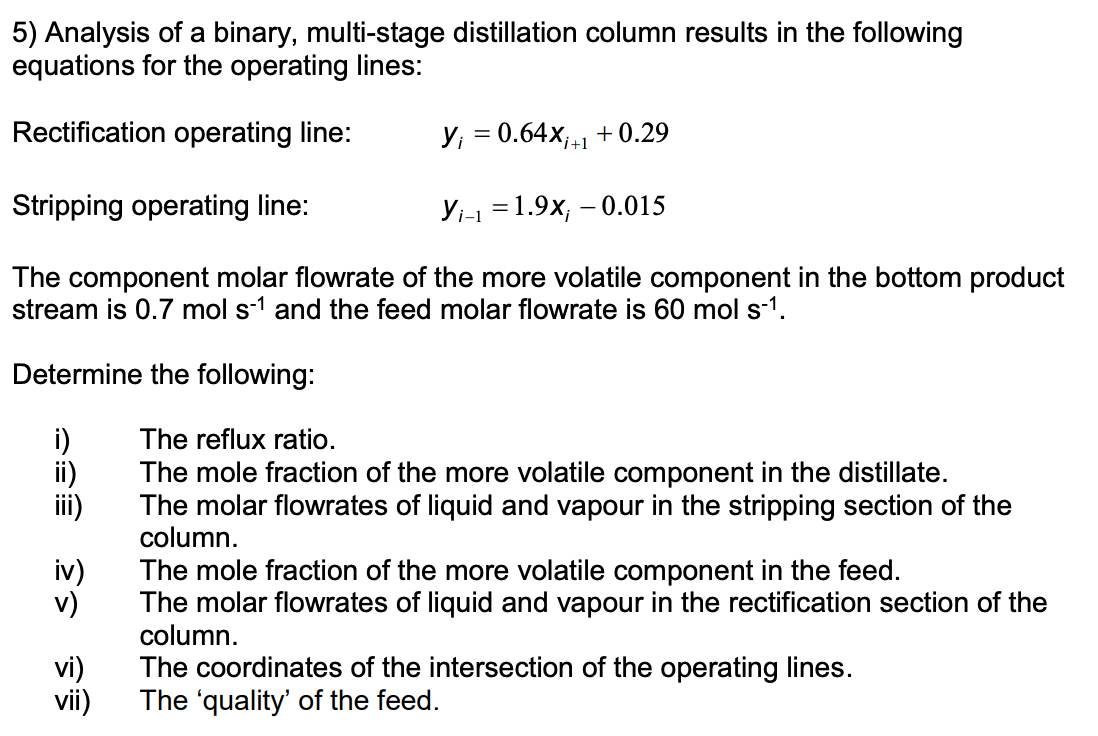

5) Analysis of a binary, multi-stage distillation column results in the following equations for the operating lines: Rectification operating line: y₁ = 0.64x₁+1+0.29 Stripping operating line: Yi-1 = 1.9x; -0.015 The component molar flowrate of the more volatile component in the bottom product stream is 0.7 mol s1 and the feed molar flowrate is 60 mol s-1. Determine the following: = = iii) iv) v) The reflux ratio. The mole fraction of the more volatile component in the distillate. The molar flowrates of liquid and vapour in the stripping section of the column. The mole fraction of the more volatile component in the feed. The molar flowrates of liquid and vapour in the rectification section of the column. vi) The coordinates of the intersection of the operating lines. vii) The 'quality' of the feed.

5) Analysis of a binary, multi-stage distillation column results in the following equations for the operating lines: Rectification operating line: y₁ = 0.64x₁+1+0.29 Stripping operating line: Yi-1 = 1.9x; -0.015 The component molar flowrate of the more volatile component in the bottom product stream is 0.7 mol s1 and the feed molar flowrate is 60 mol s-1. Determine the following: = = iii) iv) v) The reflux ratio. The mole fraction of the more volatile component in the distillate. The molar flowrates of liquid and vapour in the stripping section of the column. The mole fraction of the more volatile component in the feed. The molar flowrates of liquid and vapour in the rectification section of the column. vi) The coordinates of the intersection of the operating lines. vii) The 'quality' of the feed.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

100%

Q5. i) R=1.78; ii)xd=0.81;; iii)Vs=46.7 mol/s; Ls=88.7 mol/s; iv) xf=0.25; vi)Vr=50 mol/s ,Lr=32 mol/s; v) x=0.242; y=0.445; vii)q=0.944

feed back to help with ques:

Transcribed Image Text:5) Analysis of a binary, multi-stage distillation column results in the following

equations for the operating lines:

Rectification operating line:

y₁ = 0.64x₁+1+0.29

Stripping operating line:

Yi-1 =1.9x; -0.015

The component molar flowrate of the more volatile component in the bottom product

stream is 0.7 mol s-1 and the feed molar flowrate is 60 mol s-¹.

Determine

the following:

The reflux ratio.

The mole fraction of the more volatile component in the distillate.

The molar flowrates of liquid and vapour in the stripping section of the

column.

リ

iv)

v)

vi)

vii)

The mole fraction of the more volatile component in the feed.

The molar flowrates of liquid and vapour in the rectification section of the

column.

The coordinates of the intersection of the operating lines.

The 'quality' of the feed.

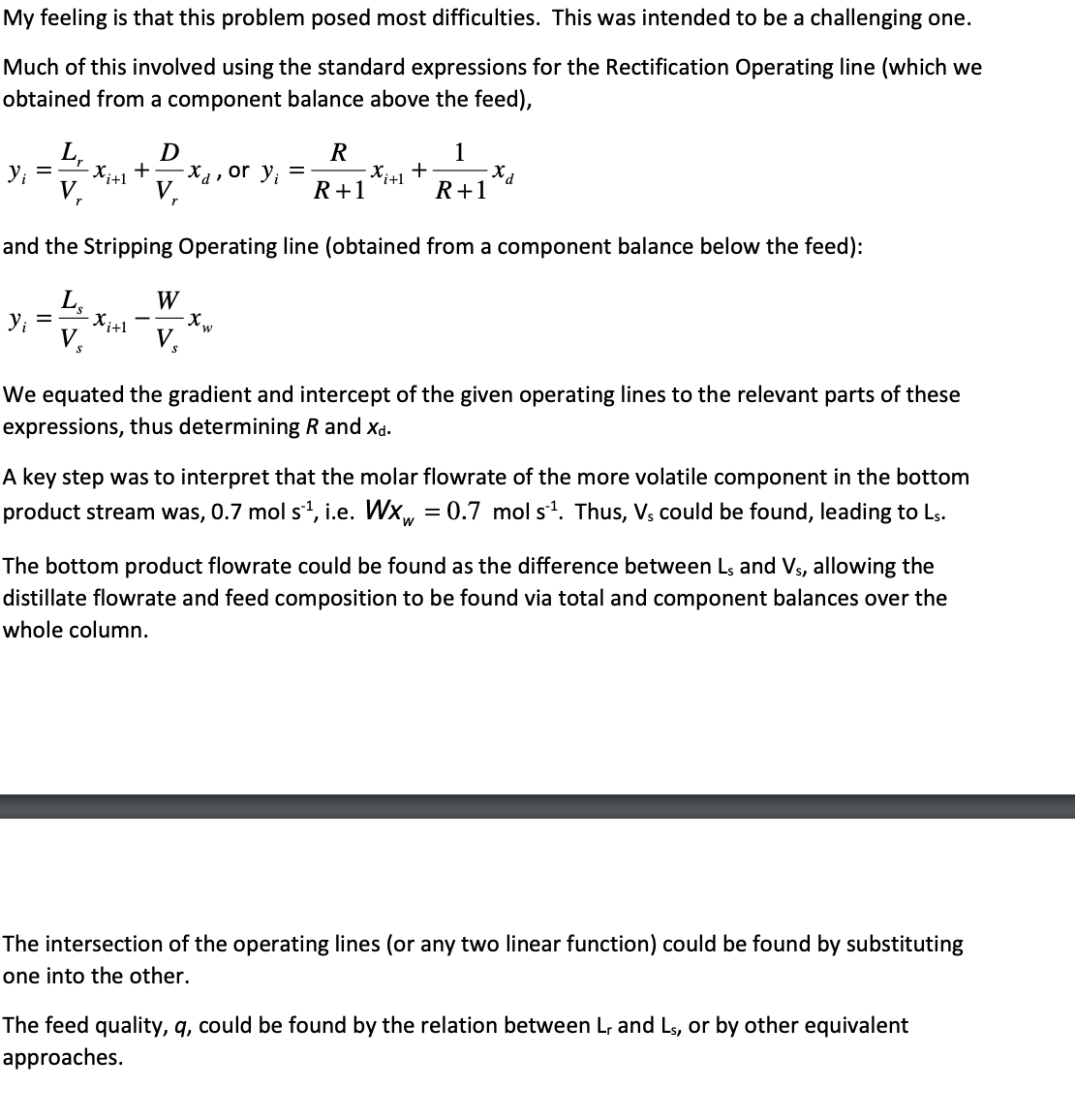

Transcribed Image Text:My feeling is that this problem posed most difficulties. This was intended to be a challenging one.

Much of this involved using the standard expressions for the Rectification Operating line (which we

obtained from a component balance above the feed),

L₁

-Xitl

+

V₁ V₂

and the Stripping Operating line (obtained from a component balance below the feed):

Yi =

Y₁ = Xitl

V₂

D

W

V₂

xa,

-Xw

or yi

R

R+1

-Xitl

+

1

R+1

-Xa

We equated the gradient and intercept of the given operating lines to the relevant parts of these

expressions, thus determining R and Xd.

A key step was to interpret that the molar flowrate of the more volatile component in the bottom

product stream was, 0.7 mol s¹¹, i.e. Wxw = 0.7 mol s¹. Thus, Vs could be found, leading to Ls.

The bottom product flowrate could be found as the difference between Ls and Vs, allowing the

distillate flowrate and feed composition to be found via total and component balances over the

whole column.

The intersection of the operating lines (or any two linear function) could be found by substituting

one into the other.

The feed quality, q, could be found by the relation between Lr and Ls, or by other equivalent

approaches.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 6 steps with 1 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The