A copra batch contains 44% oil and is to be extracted with n-hexane. The extracted meal contains 0.07 kg of oil/kg oil free matter and the mass fraction of n-hexane in it is 0.05. The extract contains 49% n- hexane. If 10,000 kg of copra are to be processed, how many kg of n-hexane are required and the determine the amount of extract.

A copra batch contains 44% oil and is to be extracted with n-hexane. The extracted meal contains 0.07 kg of oil/kg oil free matter and the mass fraction of n-hexane in it is 0.05. The extract contains 49% n- hexane. If 10,000 kg of copra are to be processed, how many kg of n-hexane are required and the determine the amount of extract.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

A copra batch contains 44% oil and is to be extracted with n-hexane. The extracted meal contains 0.07

kg of oil/kg oil free matter and the mass fraction of n-hexane in it is 0.05. The extract contains 49% n-

hexane. If 10,000 kg of copra are to be processed, how many kg of n-hexane are required and the

determine the amount of extract.

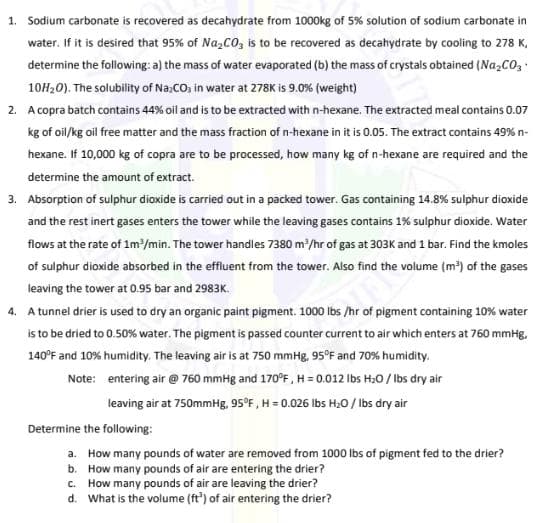

Transcribed Image Text:1. Sodium carbonate is recovered as decahydrate from 1000kg of 5% solution of sodium carbonate in

water. If it is desired that 95% of Na,CO, is to be recovered as decahydrate by cooling to 278 K,

determine the following: a) the mass of water evaporated (b) the mass of crystals obtained (Na,CO,

10H20). The solubility of Na;CO, in water at 278K is 9.0% (weight)

2. A copra batch contains 44% oil and is to be extracted with n-hexane. The extracted meal contains 0.07

kg of oil/kg oil free matter and the mass fraction of n-hexane in it is 0.05. The extract contains 49% n-

hexane. If 10,000 kg of copra are to be processed, how many kg of n-hexane are required and the

determine the amount of extract.

3. Absorption of sulphur dioxide is carried out in a packed tower. Gas containing 14.8% sulphur dioxide

and the rest inert gases enters the tower while the leaving gases contains 1% sulphur dioxide. Water

flows at the rate of 1m/min. The tower handles 7380 m/hr of gas at 303K and 1 bar. Find the kmoles

of sulphur dioxide absorbed in the effluent from the tower. Also find the volume (m') of the gases

leaving the tower at 0.95 bar and 2983K.

4. A tunnel drier is used to dry an organic paint pigment. 1000 Ibs /hr of pigment containing 10% water

is to be dried to 0.50% water. The pigment is passed counter current to air which enters at 760 mmHg,

140°F and 10% humidity. The leaving air is at 750 mmHg, 95°F and 70% humidity.

Note: entering air @ 760 mmHg and 170°F, H = 0.012 Ibs H;0 / Ibs dry air

leaving air at 750mmHg, 95°F , H = 0.026 Ibs H20 / Ibs dry air

Determine the following:

a. How many pounds of water are removed from 1000 lbs of pigment fed to the drier?

b. How many pounds of air are entering the drier?

c. How many pounds of air are leaving the drier?

d. What is the volume (ft') of air entering the drier?

Expert Solution

Trending now

This is a popular solution!

Step by step

Solved in 10 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The