A gauge # 10 HSLA steel for an automotive application has a Young’s modulus of 200 GPa, a yield strength of 370 MPa and a ultimate tensile strength of 440 MPa. What is the punch force needed to punch a square hole with a side length of 20 mm on this HSLA steel? Show your work.

A gauge # 10 HSLA steel for an automotive application has a Young’s modulus of 200 GPa, a yield strength of 370 MPa and a ultimate tensile strength of 440 MPa. What is the punch force needed to punch a square hole with a side length of 20 mm on this HSLA steel? Show your work.

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter3: Job Planning, Benchwork, And Layout

Section3.1: Understanding Drawings

Problem 1RQ: Information such as tolerances and scale can be found in the________ of an engineering drawing.

Related questions

Question

A gauge # 10 HSLA steel for an automotive application has a Young’s modulus of 200 GPa, a yield strength of 370 MPa and a ultimate tensile strength of 440 MPa. What is the punch force needed to punch a square hole with a side length of 20 mm on this HSLA steel? Show your work.

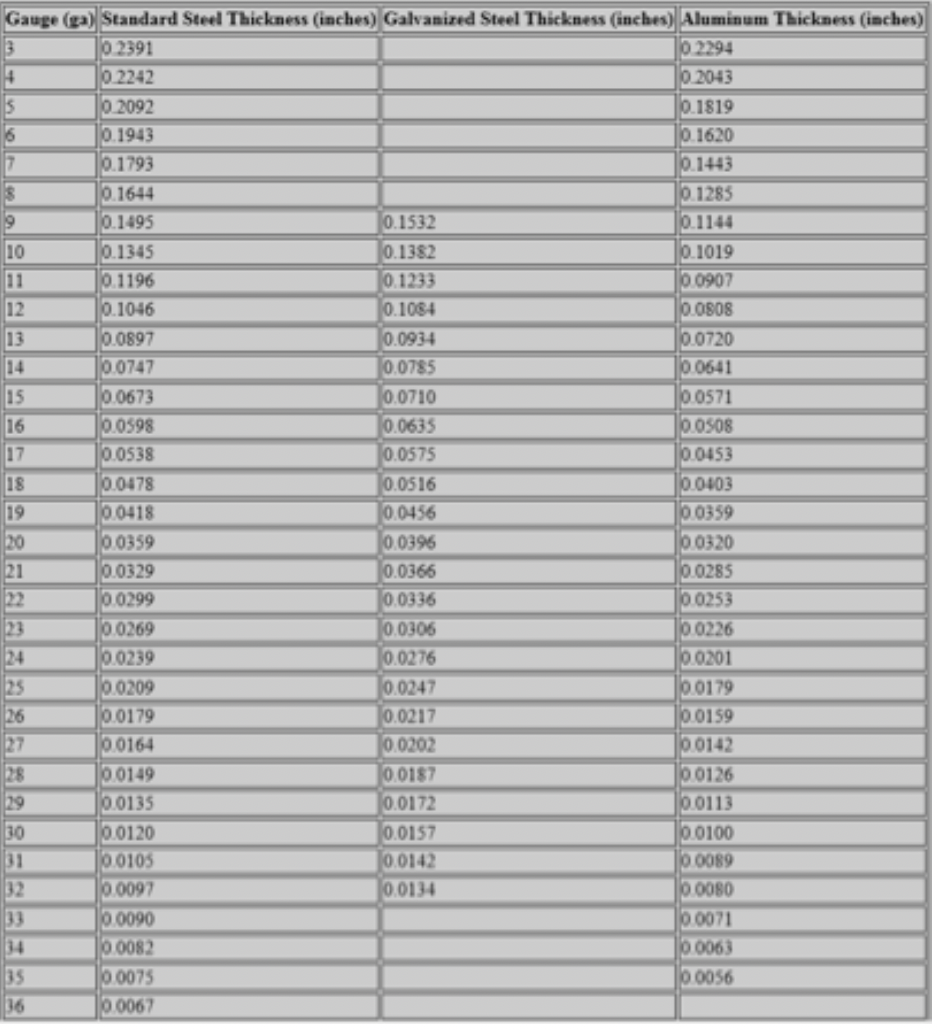

Transcribed Image Text:Gauge (ga) Standard Steel Thickness (inches) Galvanized Steel Thickness (inches) Aluminum Thickness (inches)

0.2391

0.2242

0.2092

0.1943

0.1793

0.2294

0.2043

4.

0.1819

0.1620

7

0.1443

0.1285

0.1644

0.1495

0.1532

0.1144

10

0.1345

0.1196

0.1046

0.1019

0.0907

0.1382

11

12

0.1233

0.1084

8080 0

0.0720

0.0897

0.0747

0.0673

0.0934

0.0785

0.0710

0.0635

0.0575

0.0516

0.0456

13

0.0641

0.0571

0.0508

0.0453

14

15

0.0598

0.0538

16

17

0.0478

0.0403

0.0359

18

19

0.0418

20

0.0359

0.0396

0.0366

0.0336

0.0306

0.0276

0.0247

0.0217

0.0202

0.0320

0.0285

0.0253

21

0.0329

22

0.0299

0.0269

0.0239

0.0209

0.0179

23

0.0226

24

0.0201

25

26

27

0.0179

0.0159

0.0142

0.0126

0.0164

00149

0.0135

28

0.0187

29

0.0172

0.0113

0.0120

0.0105

0.0097

0.0090

0.0100

0 0089

0.0080

0.0071

0.0063

30

31

32

33

0.0157

0.0142

0.0134

34

0.0082

0.0075

0.0067

35

o 0056

36

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning