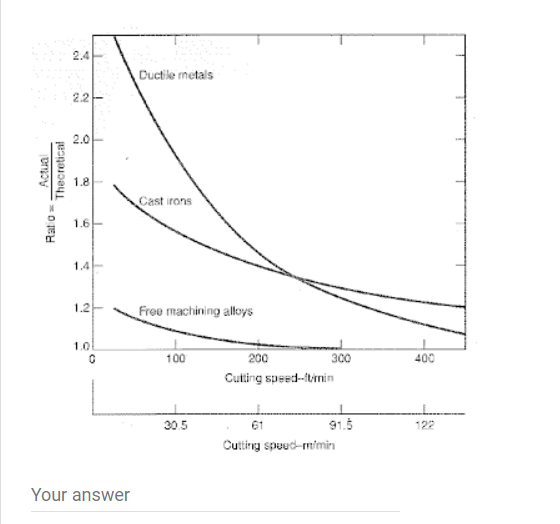

A part to be turned in an engine lathe must have a surface finish of 1.6 μm. The part is made of a free machining aluminum alloy. Cutting speed = 150 m/min. The nose radius on the tool = 0.75 mm. Determine the feed that will achieve the specified surface finish.

A part to be turned in an engine lathe must have a surface finish of 1.6 μm. The part is made of a free machining aluminum alloy. Cutting speed = 150 m/min. The nose radius on the tool = 0.75 mm. Determine the feed that will achieve the specified surface finish.

Welding: Principles and Applications (MindTap Course List)

8th Edition

ISBN:9781305494695

Author:Larry Jeffus

Publisher:Larry Jeffus

Chapter26: Welding Metallurgy

Section: Chapter Questions

Problem 42R: What is carbide precipitation?

Related questions

Question

A part to be turned in an engine lathe must have a surface finish of 1.6 μm. The part is made of a free machining aluminum alloy. Cutting speed = 150 m/min. The nose radius on the tool = 0.75 mm. Determine the feed that will achieve the specified surface finish.

Transcribed Image Text:2.4

Ductile metals

2.2

2.0

1.8

Cast irons

1.6-

1.4

1.2

Free machining alloys

1.0L

100

200

300

400

Cutting speed-itimin

30.5

61

91.5

122

Cutting speed-mimin

Your answer

Ratio=

Thecretical

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning

Welding: Principles and Applications (MindTap Cou…

Mechanical Engineering

ISBN:

9781305494695

Author:

Larry Jeffus

Publisher:

Cengage Learning