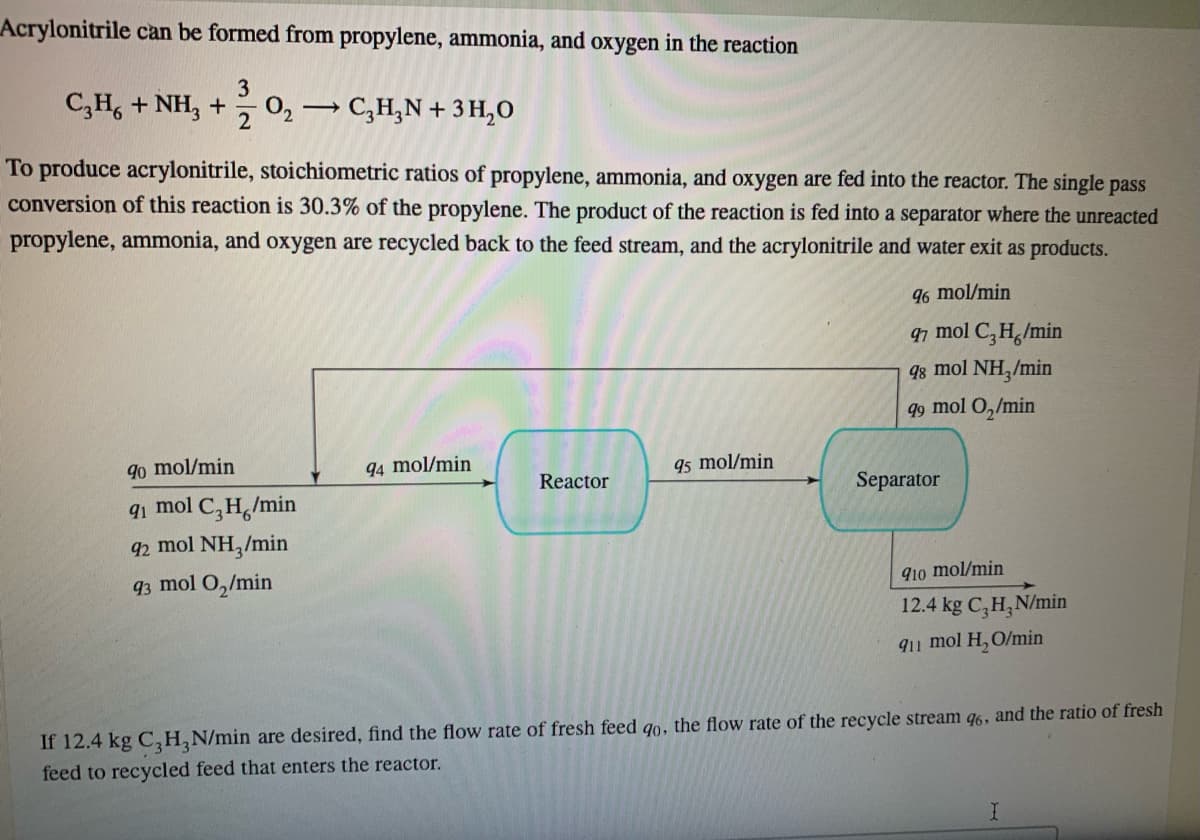

Acrylonitrile can be formed from propylene, ammonia, and oxygen in the reaction C3H6 + NH3 + 0₂ C3H₂N+ 3 H₂O 3 2 ->> To produce acrylonitrile, stoichiometric ratios of propylene, ammonia, and oxygen are fed into the reactor. The single pass conversion of this reaction is 30.3% of the propylene. The product of the reaction is fed into a separator where the unreacted propylene, ammonia, and oxygen are recycled back to the feed stream, and the acrylonitrile and water exit as products. 90 mol/min 91 mol C₂H./min 92 mol NH3/min 93 mol O₂/min 94 mol/min Reactor 95 mol/min 96 mol/min 97 mol C3H./min 98 mol NH3/min 99 mol O₂/min Separator 910 mol/min 12.4 kg C₂H₂N/min 911 mol H₂O/min If 12.4 kg C₂H₂N/min are desired, find the flow rate of fresh feed go, the flow rate of the recycle stream q6, and the ratio of fresh feed to recycled feed that enters the reactor.

Acrylonitrile can be formed from propylene, ammonia, and oxygen in the reaction C3H6 + NH3 + 0₂ C3H₂N+ 3 H₂O 3 2 ->> To produce acrylonitrile, stoichiometric ratios of propylene, ammonia, and oxygen are fed into the reactor. The single pass conversion of this reaction is 30.3% of the propylene. The product of the reaction is fed into a separator where the unreacted propylene, ammonia, and oxygen are recycled back to the feed stream, and the acrylonitrile and water exit as products. 90 mol/min 91 mol C₂H./min 92 mol NH3/min 93 mol O₂/min 94 mol/min Reactor 95 mol/min 96 mol/min 97 mol C3H./min 98 mol NH3/min 99 mol O₂/min Separator 910 mol/min 12.4 kg C₂H₂N/min 911 mol H₂O/min If 12.4 kg C₂H₂N/min are desired, find the flow rate of fresh feed go, the flow rate of the recycle stream q6, and the ratio of fresh feed to recycled feed that enters the reactor.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Please post steps!!

Transcribed Image Text:Acrylonitrile can be formed from propylene, ammonia, and oxygen in the reaction

3

C3H6 + NH3 + O₂ →

2

->

C3H₂N+ 3 H₂O

To produce acrylonitrile, stoichiometric ratios of propylene, ammonia, and oxygen are fed into the reactor. The single pass

conversion of this reaction is 30.3% of the propylene. The product of the reaction is fed into a separator where the unreacted

propylene, ammonia, and oxygen are recycled back to the feed stream, and the acrylonitrile and water exit as products.

90 mol/min

91 mol C3H./min

92 mol NH3/min

93 mol O₂/min

94 mol/min

Reactor

95 mol/min

96 mol/min

97 mol C₂H./min

g8 mol NH,/min

99 mol O₂/min

Separator

910 mol/min

12.4 kg C₂H₂N/min

911 mol H₂O/min

If 12.4 kg C₂H₂N/min are desired, find the flow rate of fresh feed go, the flow rate of the recycle stream 96, and the ratio of fresh

feed to recycled feed that enters the reactor.

I

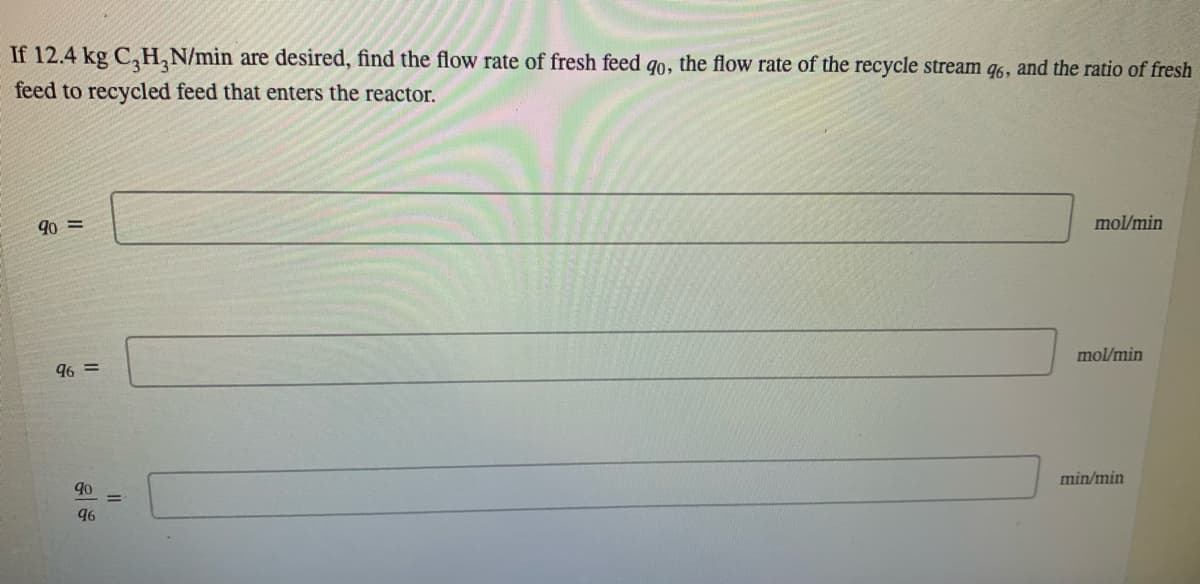

Transcribed Image Text:If 12.4 kg C₂H₂N/min are desired, find the flow rate of fresh feed go, the flow rate of the recycle stream q6, and the ratio of fresh

feed to recycled feed that enters the reactor.

90=

96 =

90

96

mol/min

mol/min

min/min

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The