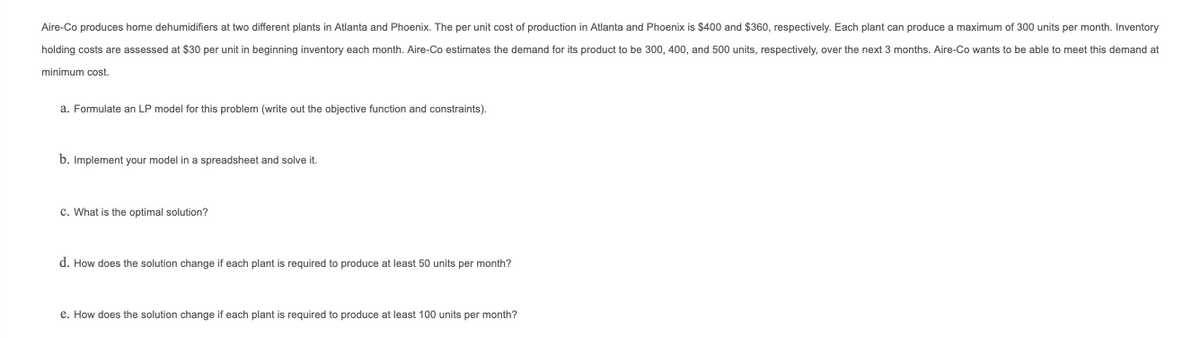

Aire-Co produces home dehumidifiers at two different plants in Atlanta and Phoenix. The per unit cost of production in Atlanta and Phoenix is $400 and $360, respectively. Each plant can produce a maximum of 300 units per month. Inventory holding costs are assessed at $30 per unit in beginning inventory each month. Aire-Co estimates the demand for its product to be 300, 400, and 500 units, respectively, over the next 3 months. Aire-Co wants to be able to meet this demand at minimum cost. a. Formulate an LP model for this problem (write out the objective function and constraints). b. Implement your model in a spreadsheet and solve it. c. What is the optimal solution? d. How does the solution change if each plant required to produce at least 50 units per month? e. How does the solution change if each plant is required to produce at least 100 units per month?

Aire-Co produces home dehumidifiers at two different plants in Atlanta and Phoenix. The per unit cost of production in Atlanta and Phoenix is $400 and $360, respectively. Each plant can produce a maximum of 300 units per month. Inventory holding costs are assessed at $30 per unit in beginning inventory each month. Aire-Co estimates the demand for its product to be 300, 400, and 500 units, respectively, over the next 3 months. Aire-Co wants to be able to meet this demand at minimum cost. a. Formulate an LP model for this problem (write out the objective function and constraints). b. Implement your model in a spreadsheet and solve it. c. What is the optimal solution? d. How does the solution change if each plant required to produce at least 50 units per month? e. How does the solution change if each plant is required to produce at least 100 units per month?

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter4: Linear Programming Models

Section: Chapter Questions

Problem 107P

Related questions

Question

Transcribed Image Text:Aire-Co produces home dehumidifiers at two different plants in Atlanta and Phoenix. The per unit cost of production in Atlanta and Phoenix is $400 and $360, respectively. Each plant can produce a maximum of 300 units per month. Inventory

holding costs are assessed at $30 per unit

beginning inventory each month. Aire-Co estimates the demand for its product to be 300, 400, and 500 units, respectively, over the next 3 months. Aire-Co wants to be able to meet this demand at

minimum cost.

a. Formulate an LP model for this problem (write out the objective function and constraints).

b. Implement your model in a spreadsheet and solve it.

c. What is the optimal solution?

d. How does the solution change if each plant

required to produce at least 50 units per month?

e. How does the solution change if each plant is required to produce at least 100 units per month?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,