Chemical Engineering: Material Balance

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

100%

Use the atomic species balance for this. Chemical Engineering: Material Balance.

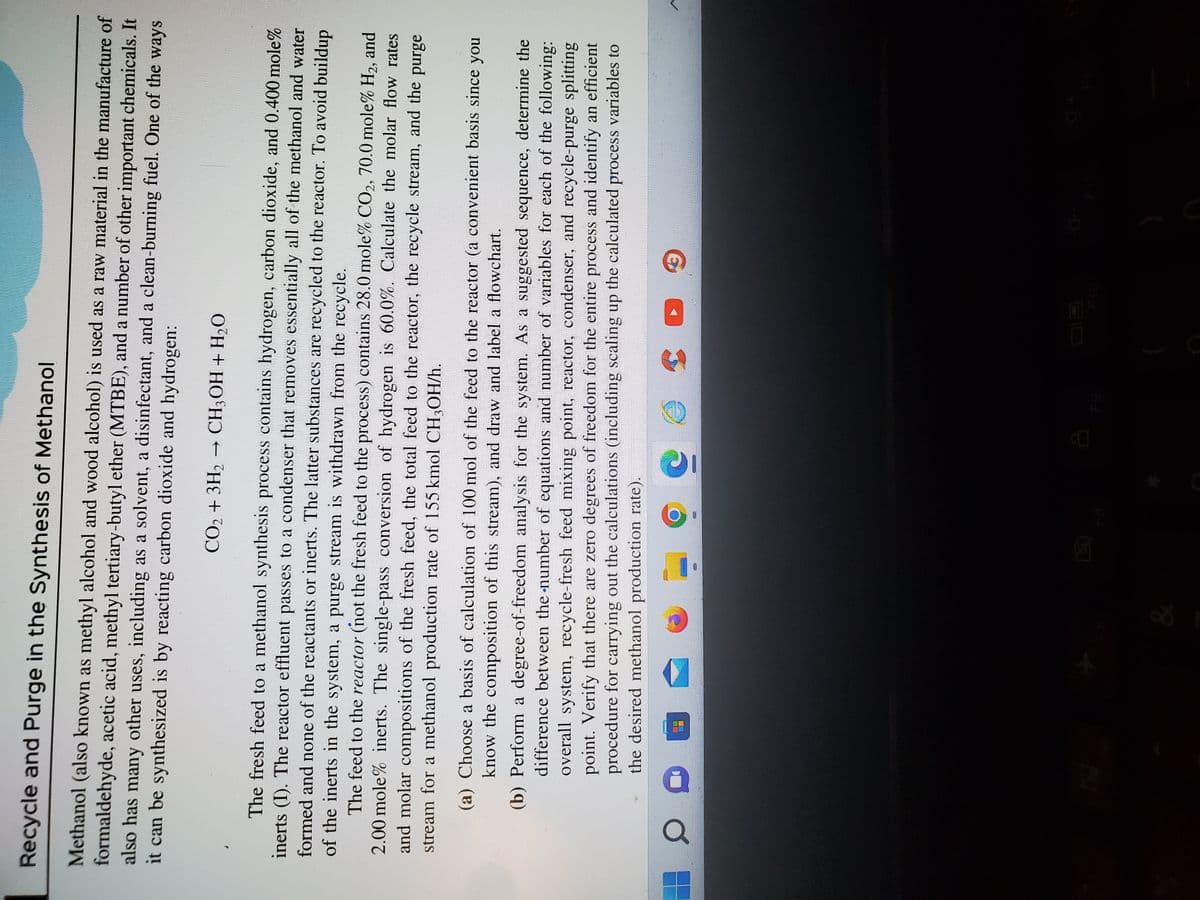

Transcribed Image Text:Recycle and Purge in the Synthesis of Methanol

Methanol (also known as methyl alcohol and wood alcohol) is used as a raw material in the manufacture of

formaldehyde, acetic acid, methyl tertiary-butyl ether (MTBE), and a number of other important chemicals. It

also has many other uses, including as a solvent, a disinfectant, and a clean-burning fuel. One of the ways

it can be synthesized is by reacting carbon dioxide and hydrogen:

CO₂ + 3H₂ CH3OH + H₂O

-

The fresh feed to a methanol synthesis process contains hydrogen, carbon dioxide, and 0.400 mole%

inerts (I). The reactor effluent passes to a condenser that removes essentially all of the methanol and water

formed and none of the reactants or inerts. The latter substances are recycled to the reactor. To avoid buildup

of the inerts in the system, a purge stream is withdrawn from the recycle.

The feed to the reactor (not the fresh feed to the process) contains 28.0 mole% CO2, 70.0 mole% H₂, and

2.00 mole% inerts. The single-pass conversion of hydrogen is 60.0%. Calculate the molar flow rates

and molar compositions of the fresh feed, the total feed to the reactor, the recycle stream, and the purge

stream for a methanol production rate of 155 kmol CH3OH/h.

(a) Choose a basis of calculation of 100 mol of the feed to the reactor (a convenient basis since you

know the composition of this stream), and draw and label a flowchart.

(b) Perform a degree-of-freedom analysis for the system. As a suggested sequence, determine the

difference between the number of equations and number of variables for each of the following:

overall system, recycle-fresh feed mixing point, reactor, condenser, and recycle-purge splitting

point. Verify that there are zero degrees of freedom for the entire process and identify an efficient

procedure for carrying out the calculations (including scaling up the calculated process variables to

the desired methanol production rate).

€

3

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 3 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The