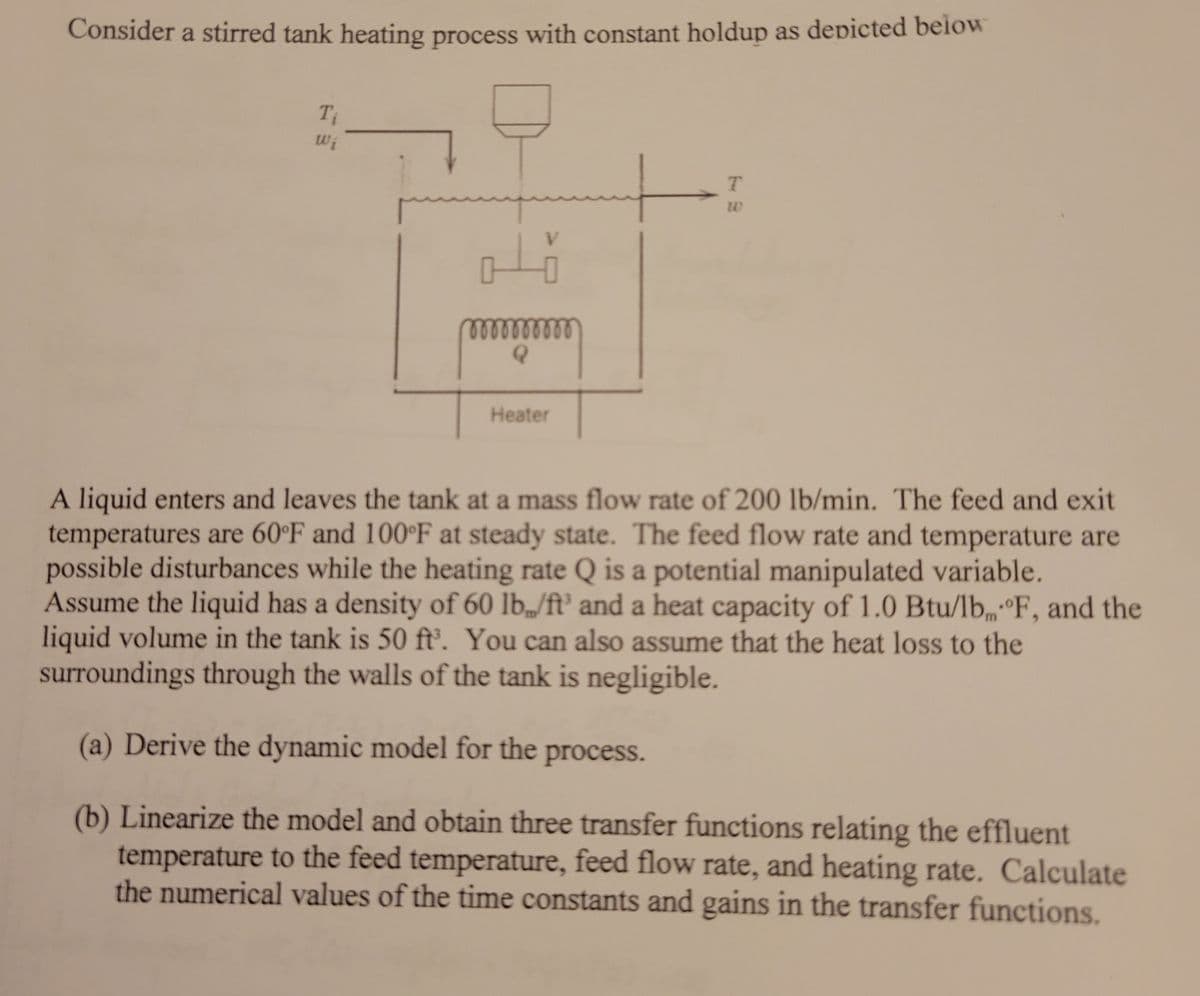

Consider a stirred tank heating process with constant holdup as depicted beiow Ti Wi Heater A liquid enters and leaves the tank at a mass flow rate of 200 lb/min. The feed and exit temperatures are 60°F and 100°F at steady state. The feed flow rate and temperature are possible disturbances while the heating rate Q is a potential manipulated variable. Assume the liquid has a density of 60 lb„/ft' and a heat capacity of 1.0 Btu/I.°F, and the iquid volume in the tank is 50 ft'. You can also assume that the heat loss to the surroundings through the walls of the tank is negligible. (a) Derive the dynamic model for the process. (b) Linearize the model and obtain three transfer functions relating the effluent temperature to the feed temperature, feed flow rate, and heating rate. Calculate the numerical values of the time constants and gains in the transfer functions.

Consider a stirred tank heating process with constant holdup as depicted beiow Ti Wi Heater A liquid enters and leaves the tank at a mass flow rate of 200 lb/min. The feed and exit temperatures are 60°F and 100°F at steady state. The feed flow rate and temperature are possible disturbances while the heating rate Q is a potential manipulated variable. Assume the liquid has a density of 60 lb„/ft' and a heat capacity of 1.0 Btu/I.°F, and the iquid volume in the tank is 50 ft'. You can also assume that the heat loss to the surroundings through the walls of the tank is negligible. (a) Derive the dynamic model for the process. (b) Linearize the model and obtain three transfer functions relating the effluent temperature to the feed temperature, feed flow rate, and heating rate. Calculate the numerical values of the time constants and gains in the transfer functions.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Transcribed Image Text:Consider a stirred tank heating process with constant holdup as depicted beiow

Wi

V.

lelllll

Heater

A liquid enters and leaves the tank at a mass flow rate of 200 lb/min. The feed and exit

temperatures are 60°F and 100°F at steady state. The feed flow rate and temperature are

possible disturbances while the heating rate Q is a potential manipulated variable.

Assume the liquid has a density of 60 lb„/ft' and a heat capacity of 1.0 Btu/lb°F, and the

liquid volume in the tank is 50 ft. You can also assume that the heat loss to the

surroundings through the walls of the tank is negligible.

(a) Derive the dynamic model for the process.

(b) Linearize the model and obtain three transfer functions relating the effluent

temperature to the feed temperature, feed flow rate, and heating rate. Calculate

the numerical values of the time constants and gains in the transfer functions.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 1 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The