Consider the following specific information: ⚫ There is a constant 500 L volume in the tank. The inlet flow rate is held constant at 40 L/min. There are constant liquid properties: 0.8 kg/L density & 0.5 cal/g.°C heat capacity. When the inlet temperature is 45°C, an outlet temperature of 65°C can be obtained with 180°C steam. (d) What are the numeric values for K., K, and T based on the specific information? (e) (f) We want to consider a step change of 10°C for the inlet temperature while keeping the set point temperature constant. Graph the response of the change in the outlet temperature from 0 to 20 min when t₁ =1 min and K₁ = 10. We want to consider a step change of 10°C for the set point temperature while keeping the inlet temperature constant. Graph the responses for the outlet temperature when t = 1 min and K = 10.

Consider the following specific information: ⚫ There is a constant 500 L volume in the tank. The inlet flow rate is held constant at 40 L/min. There are constant liquid properties: 0.8 kg/L density & 0.5 cal/g.°C heat capacity. When the inlet temperature is 45°C, an outlet temperature of 65°C can be obtained with 180°C steam. (d) What are the numeric values for K., K, and T based on the specific information? (e) (f) We want to consider a step change of 10°C for the inlet temperature while keeping the set point temperature constant. Graph the response of the change in the outlet temperature from 0 to 20 min when t₁ =1 min and K₁ = 10. We want to consider a step change of 10°C for the set point temperature while keeping the inlet temperature constant. Graph the responses for the outlet temperature when t = 1 min and K = 10.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

need d-f

note: a-c don't need to go past transfer function form

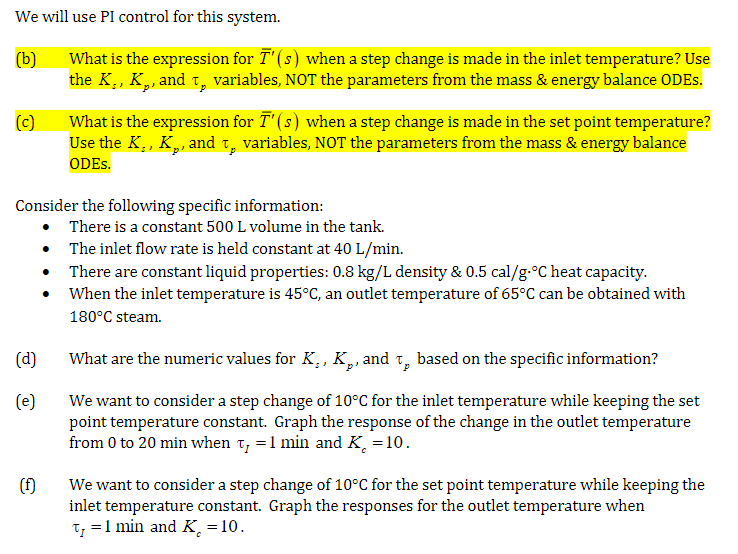

Transcribed Image Text:We will use PI control for this system.

(b)

(c)

What is the expression for T'(s) when a step change is made in the inlet temperature? Use

the K., K., and t, variables, NOT the parameters from the mass & energy balance ODES.

What is the expression for T'(s) when a step change is made in the set point temperature?

Use the K., K., and ɩ variables, NOT the parameters from the mass & energy balance

ODES.

Consider the following specific information:

(d)

(e)

(f)

• There is a constant 500 L volume in the tank.

The inlet flow rate is held constant at 40 L/min.

There are constant liquid properties: 0.8 kg/L density & 0.5 cal/g.°C heat capacity.

When the inlet temperature is 45°C, an outlet temperature of 65°C can be obtained with

180°C steam.

What are the numeric values for K., K, and t, based on the specific information?

We want to consider a step change of 10°C for the inlet temperature while keeping the set

point temperature constant. Graph the response of the change in the outlet temperature

from 0 to 20 min when t₁ =1 min and K = 10.

We want to consider a step change of 10°C for the set point temperature while keeping the

inlet temperature constant. Graph the responses for the outlet temperature when

T = 1 min and K₁ = 10.

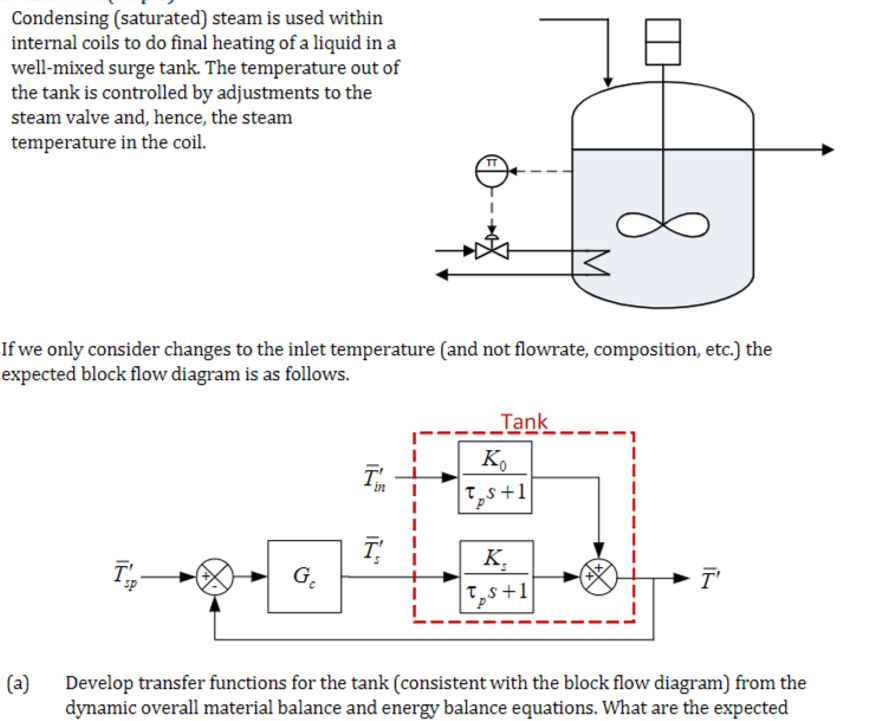

Transcribed Image Text:Condensing (saturated) steam is used within

internal coils to do final heating of a liquid in a

well-mixed surge tank. The temperature out of

the tank is controlled by adjustments to the

steam valve and, hence, the steam

temperature in the coil.

If we only consider changes to the inlet temperature (and not flowrate, composition, etc.) the

expected block flow diagram is as follows.

T

G₁

sp

ˊ

Tank

Ko

K

ps+1

T'

(a) Develop transfer functions for the tank (consistent with the block flow diagram) from the

dynamic overall material balance and energy balance equations. What are the expected

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 6 steps with 25 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The