Design a tubular feed-water heater which need to heat the 1.5 kg/s of water from 20°C to 60°C. Constraints: a) Heating of water need to be done by saturated steam which is condensing at 1 MPa & heat transfer coefficients (on steam side) is 6500 W/m2K b) Max. Velocity of water 1.0 m/s c) Three different copper tube inner diameters 2.0 cm, 2.5 cm and 3.0 cm. d) Thickness of copper tubes 10% of the inner diameter.

Design a tubular feed-water heater which need to heat the 1.5 kg/s of water from 20°C to 60°C. Constraints: a) Heating of water need to be done by saturated steam which is condensing at 1 MPa & heat transfer coefficients (on steam side) is 6500 W/m2K b) Max. Velocity of water 1.0 m/s c) Three different copper tube inner diameters 2.0 cm, 2.5 cm and 3.0 cm. d) Thickness of copper tubes 10% of the inner diameter.

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter10: Heat Exchangers

Section: Chapter Questions

Problem 10.40P

Related questions

Question

Design a tubular feed-water heater which need to heat the 1.5 kg/s of water from

20°C to 60°C.

Constraints:

a) Heating of water need to be done by saturated steam which is condensing at

1 MPa & heat transfer coefficients (on steam side) is 6500 W/m2K

b) Max. Velocity of water 1.0 m/s

c) Three different copper tube inner diameters 2.0 cm, 2.5 cm and 3.0 cm.

d) Thickness of copper tubes 10% of the inner diameter.

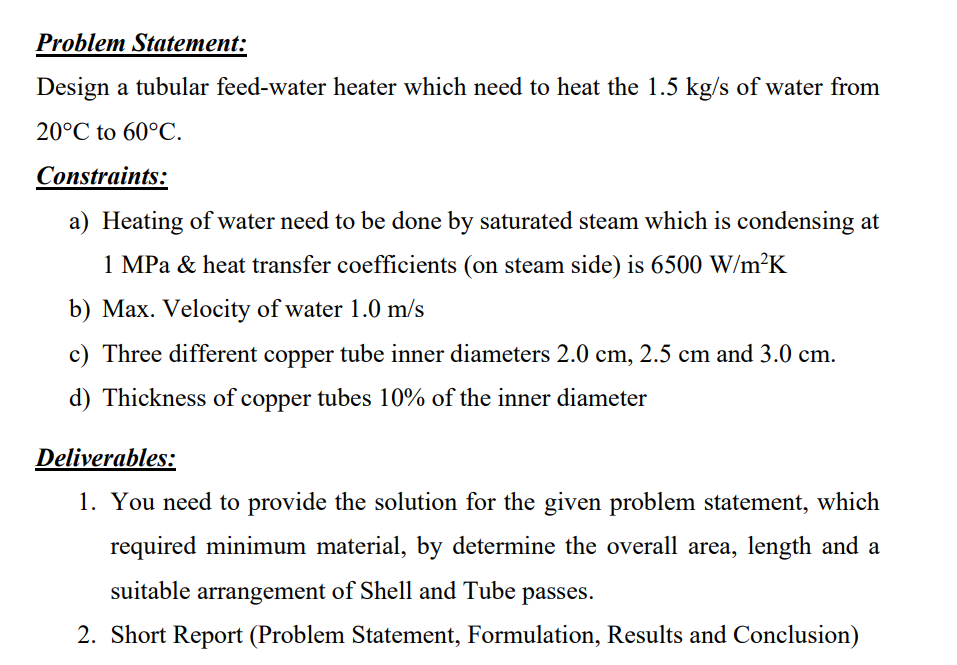

Transcribed Image Text:Problem Statement:

Design a tubular feed-water heater which need to heat the 1.5 kg/s of water from

20°C to 60°C.

Constraints:

a) Heating of water need to be done by saturated steam which is condensing at

1 MPa & heat transfer coefficients (on steam side) is 6500 W/m²K

b) Max. Velocity of water 1.0 m/s

c) Three different copper tube inner diameters 2.0 cm, 2.5 cm and 3.0 cm.

d) Thickness of copper tubes 10% of the inner diameter

Deliverables:

1. You need to provide the solution for the given problem statement, which

required minimum material, by determine the overall area, length and a

suitable arrangement of Shell and Tube passes.

2. Short Report (Problem Statement, Formulation, Results and Conclusion)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning