distillation column is to be designed to produce 99.5% pure oxygen from air

distillation column is to be designed to produce 99.5% pure oxygen from air

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Relatively pure oxygen is required in a large number of applications ranging from

incubators for premature babies in neo-natal intensive care units to the use of

oxygenation reactions in the production of various chemicals. An attractive way of

generating this high purity oxygen is to use a small distillation column, with oxygen

removed in the bottoms. The distillate, which is simply a more concentrated nitrogen

stream, can be directly discharged into the atmosphere. The column obviously operates

at very low temperatures (typically referred to as cryogenic distillation) to attain the

desired VLE for the O2-N2 system.

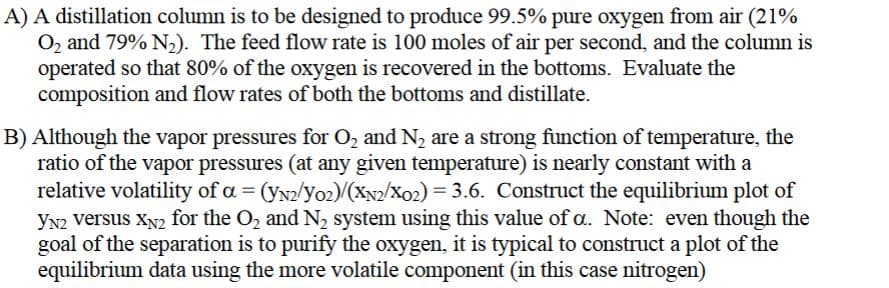

Transcribed Image Text:A) A distillation column is to be designed to produce 99.5% pure oxygen from air (21%

O₂ and 79% N₂). The feed flow rate is 100 moles of air per second, and the column is

operated so that 80% of the oxygen is recovered in the bottoms. Evaluate the

composition and flow rates of both the bottoms and distillate.

B) Although the vapor pressures for O₂ and N₂ are a strong function of temperature, the

ratio of the vapor pressures (at any given temperature) is nearly constant with a

relative volatility of a = (YN2/Y02)/(XN2/X02) = 3.6. Construct the equilibrium plot of

YN2 versus XN2 for the O₂ and N₂ system using this value of a. Note: even though the

goal of the separation is to purify the oxygen, it is typical to construct a plot of the

equilibrium data using the more volatile component (in this case nitrogen)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 5 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The