Ethanol-Water Separations.

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

100%

Solve d) clearly show the Txy graph

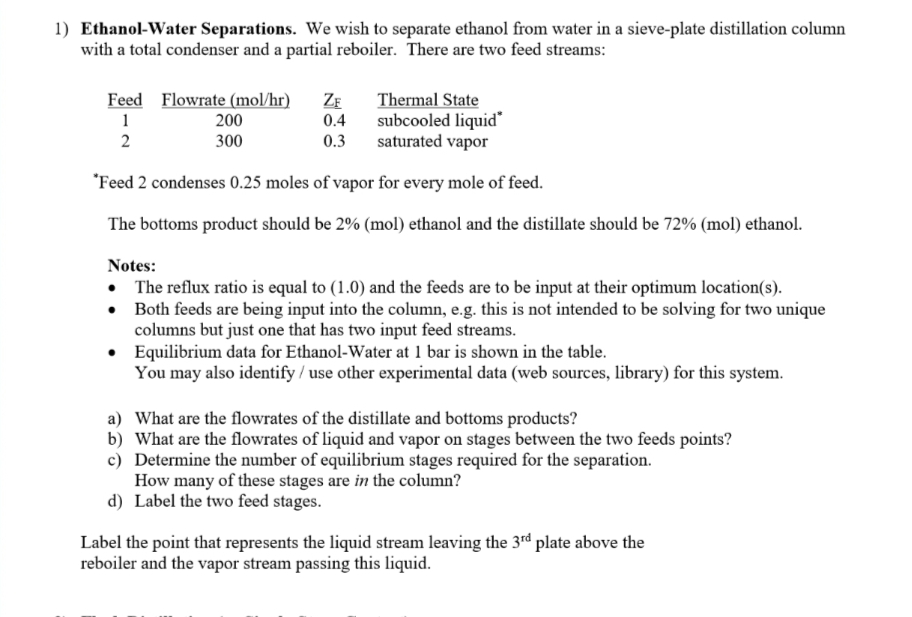

Transcribed Image Text:1) Ethanol-Water Separations. We wish to separate ethanol from water in a sieve-plate distillation column

with a total condenser and a partial reboiler. There are two feed streams:

Thermal State

subcooled liquid*

saturated vapor

*Feed 2 condenses 0.25 moles of vapor for every mole of feed.

The bottoms product should be 2% (mol) ethanol and the distillate should be 72% (mol) ethanol.

Feed Flowrate (mol/hr) ZF

1

0.4

2

0.3

200

300

Notes:

• The reflux ratio is equal to (1.0) and the feeds are to be input at their optimum location(s).

•

Both feeds are being input into the column, e.g. this is not intended to be solving for two unique

columns but just one that has two input feed streams.

•

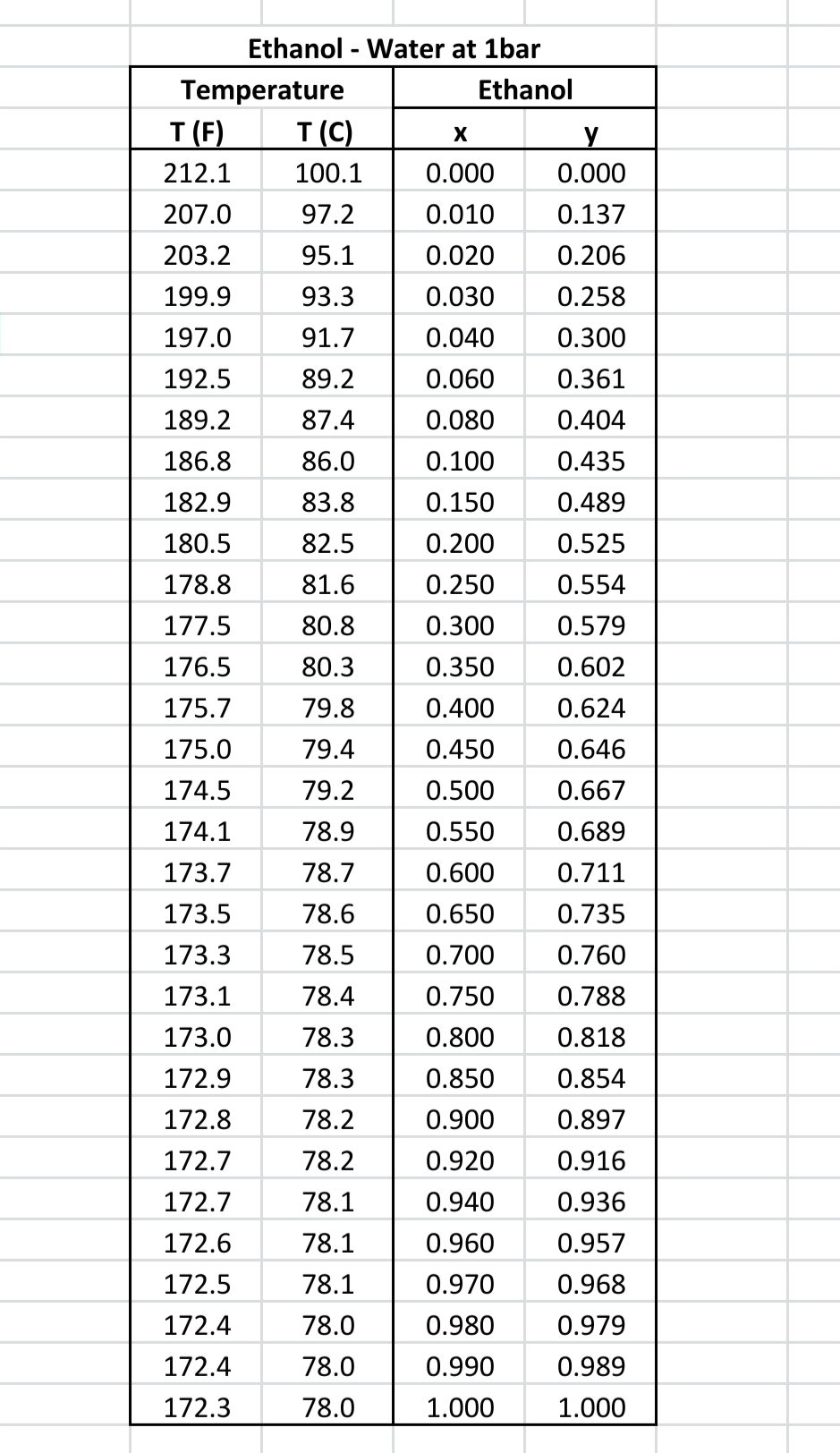

Equilibrium data for Ethanol-Water at 1 bar is shown in the table.

You may also identify /use other experimental data (web sources, library) for this system.

a) What are the flowrates of the distillate and bottoms products?

b)

What are the flowrates of liquid and vapor on stages between the two feeds points?

Determine the number of equilibrium stages required for the separation.

c)

How many of these stages are in the column?

d) Label the two feed stages.

Label the point that represents the liquid stream leaving the 3rd plate above the

reboiler and the vapor stream passing this liquid.

Transcribed Image Text:Ethanol - Water at 1bar

Temperature

T (C)

100.1

97.2

95.1

93.3

91.7

89.2

87.4

86.0

83.8

82.5

81.6

80.8

80.3

79.8

79.4

79.2

78.9

78.7

78.6

78.5

78.4

78.3

78.3

78.2

78.2

78.1

78.1

78.1

78.0

78.0

78.0

T (F)

212.1

207.0

203.2

199.9

197.0

192.5

189.2

186.8

182.9

180.5

178.8

177.5

176.5

175.7

175.0

174.5

174.1

173.7

173.5

173.3

173.1

173.0

172.9

172.8

172.7

172.7

172.6

172.5

172.4

172.4

172.3

Ethanol

X

0.000

0.010

0.020

0.030

0.040

0.060

0.080

0.100

0.150

0.200

0.250

0.300

0.350

0.400

0.450

0.500

0.550

0.600

0.650

0.700

0.750

0.800

0.850

0.900

0.920

0.940

0.960

0.970

0.980

0.990

1.000

y

0.000

0.137

0.206

0.258

0.300

0.361

0.404

0.435

0.489

0.525

0.554

0.579

0.602

0.624

0.646

0.667

0.689

0.711

0.735

0.760

0.788

0.818

0.854

0.897

0.916

0.936

0.957

0.968

0.979

0.989

1.000

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 5 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The