Four hundred and fifty lbmol/h (204 kmol/h) of a mixture of 60 mol% benzene (LK) and 40 mol% toluene (HK) is to be separated into a liquid distillate and a liquid bottoms product of 95 mol% and 5 mol % benzene, respectively. The feed enters the column with a molar per- vaporization equal to the distillate-to-feed ratio. Use the McCabe-Thiele method to compute, at 1 atm (101.3 kPa): (a) Nmin, and the optimal feed-stage location. Also, compare the results with (b) Amin, and (c) number of equilibrium stages N, for R/Rmin: 1.3, those from a process simulator. and cent

Four hundred and fifty lbmol/h (204 kmol/h) of a mixture of 60 mol% benzene (LK) and 40 mol% toluene (HK) is to be separated into a liquid distillate and a liquid bottoms product of 95 mol% and 5 mol % benzene, respectively. The feed enters the column with a molar per- vaporization equal to the distillate-to-feed ratio. Use the McCabe-Thiele method to compute, at 1 atm (101.3 kPa): (a) Nmin, and the optimal feed-stage location. Also, compare the results with (b) Amin, and (c) number of equilibrium stages N, for R/Rmin: 1.3, those from a process simulator. and cent

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Redo Example 7.1, keeping everything the same but assuming a relative volatility of 1.7.

Transcribed Image Text:and Toluene.

EXAMPLE 7.1 Distillation of a Mixture of Benzene

Four hundred and fifty lbmol/h (204 kmol/h) of a mixture of 60 mol%

liquid distillate and a liquid bottoms product of 95 mol% and 5 mol %

benzene (LK) and 40 mol % toluene (HK) is to be separated into a

, respectively. The feed enters the column with a molar per-

vaporization equal to the distillate-to-feed ratio. Use the

McCabe-Thiele method to compute, at 1 atm (101.3 kPa): (a) min,

(b) Rmin, and (c) number of equilibrium stages N, for R/Rmin = 1.3,

and the optimal feed-stage location. Also, compare the results with

benzene,

cent

those from a process s

Solution

simulator.

First calculate D and B. An overall material balance on benzene

gives

From (7-26),

0.60(450) = 0.95D +0.05B

450D + B

A total balance gives

Combining (1) and (2) and solving, D = 275 lbmol/h, B = 175

Ibmol/h, and D/F = 0.611. Thus, the molar vaporization of the feed

is 61.1%.

Calculate the slope of the q-line:

VF/F = D/F = 0.611, and g for a partially vaporized feed is

LF (F-VF)

F

F

the slope of the q-line is

= 1

9

q-1

=

VF

F

= 0.389

0.389

0.389-1

= -0.637

R

1.59

= 0.614

R+1 1.59 + 1

(1)

(2)

=

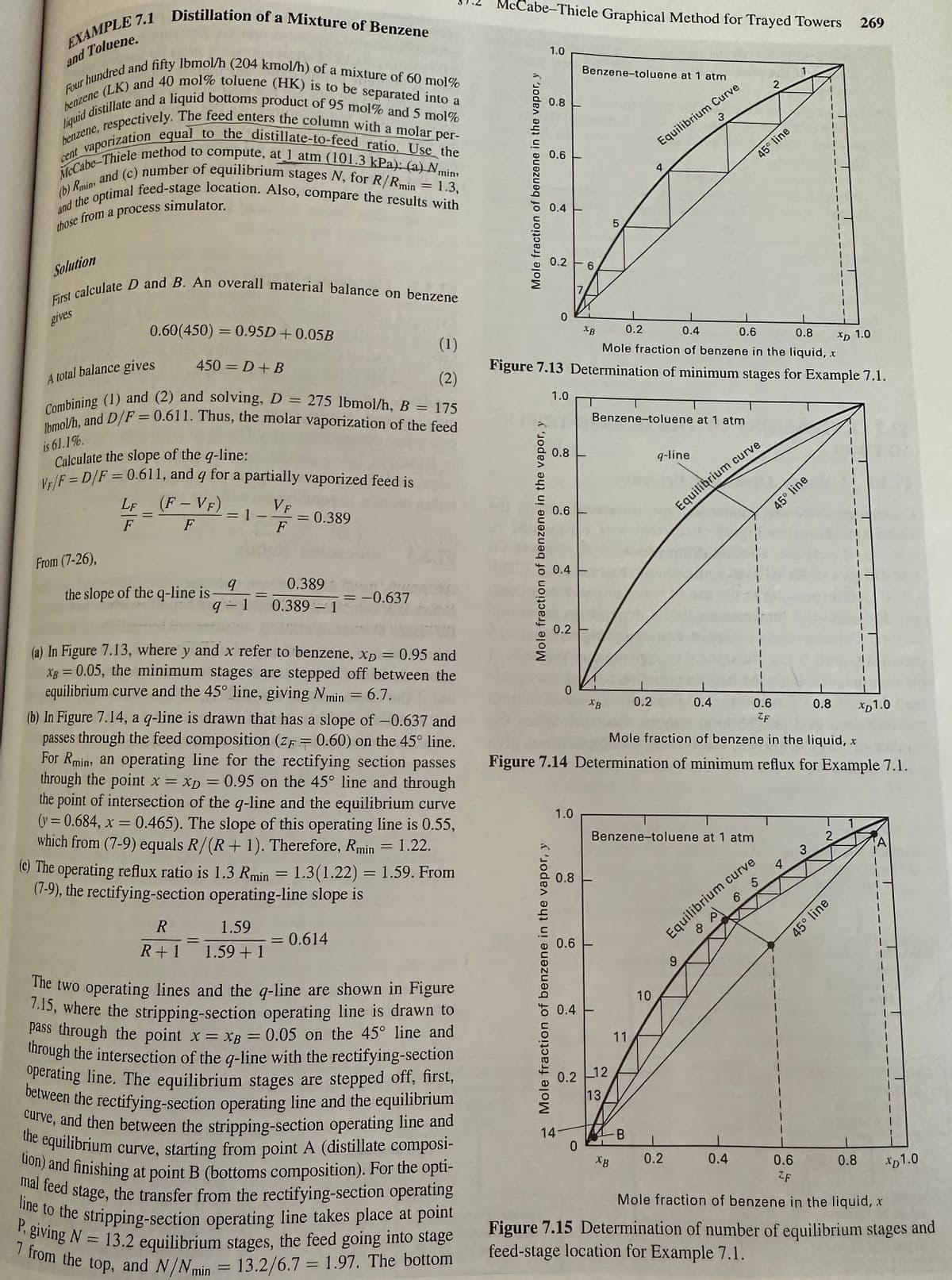

(a) In Figure 7.13, where y and x refer to benzene, xp = 0.95 and

x = 0.05, the minimum stages are stepped off between the

equilibrium curve and the 45° line, giving Nmin = 6.7.

(b) In Figure 7.14, a q-line is drawn that has a slope of -0.637 and

passes through the feed composition (z= 0.60) on the 45° line.

For Rmin, an operating line for the rectifying section passes

through the point x = xp = 0.95 on the 45° line and through

the point of intersection of the q-line and the equilibrium curve

(y=0.684, x = 0.465). The slope of this operating line is 0.55,

which from (7-9) equals R/(R+ 1). Therefore, Rmin = 1.22.

(c) The operating reflux ratio is 1.3 Rmin = 1.3 (1.22) = 1.59. From

(7-9), the rectifying-section operating-line slope is

=

XB

The two operating lines and the q-line are shown in Figure

7.15, where the stripping-section operating line is drawn to

pass through the point x = xp = 0.05 on the 45° line and

through the intersection of the q-line with the rectifying-section

operating line. The equilibrium stages are stepped off, first,

between the rectifying-section operating line and the equilibrium

curve, and then between the stripping-section operating line and

the equilibrium curve, starting from point A (distillate composi-

tion) and finishing at point B (bottoms composition). For the opti-

mal feed stage, the transfer from the rectifying-section operating

line to the stripping-section operating line takes place at point

P, giving N= 13.2 equilibrium stages, the feed going into stage

7 from the top, and N/Nmin

=

= 13.2/6.7 1.97. The bottom

N

Cabe-Thiele Graphical Method for Trayed Towers

Mole fraction of benzene in the vapor, y

Mole fraction of benzene in the vapor, y

1.0

0.8

0.6

0.4

Mole fraction of benzene in the vapor, y

0.2

0

1.0

0.8

0.6

0.4

0.2

0

0.4

0.6

0.8

XD 1.0

Mole fraction of benzene in the liquid, x

Figure 7.13 Determination of minimum stages for Example 7.1.

1.0

0.8

0.6

0.4

Benzene-toluene at 1 atm

14-

6

XB

0

XB

LO

0.2 12

13,

5

0.2

Benzene-toluene at 1 atm

XB

0.6

xD 1.0

ZF

Mole fraction of benzene in the liquid, x

Figure 7.14 Determination of minimum reflux for Example 7.1.

Equilibrium Curve

0.2

11

4

B

10

q-line

Benzene-toluene at 1 atm

Equilibrium

0.4

0.2

45° line

curve

9

Equilibrium curve

6

5

0.4

45° line

4

1

0.6

ZF

0.8

3

269

2

45° line

A

0.8 x1.0

Mole fraction of benzene in the liquid, x

Figure 7.15 Determination of number of equilibrium stages and

feed-stage location for Example 7.1.

Expert Solution

Trending now

This is a popular solution!

Step by step

Solved in 10 steps with 10 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The