he production rate per day = units. (Enter your response as a whole number.) l in the table below. (Enter your responses as whole numbers.) Month 1 January Deman 900 2 February 3 March 4 April 5 May 6 June 700 800 1,200 1,500 1,100 he total regular production cost = S (Enter your response as a whole number.) he total subcontracting cost = $(Enter your response as a whole number.) otal cost with plan 5 = S (Enter your response as a whole number.) Juarez has yet a sixth plan. A constant workforce of 7 is selected, with the remainder of demand filled by subcontracting. Evaluate this plan. be production rate ner day =llunite (Enter vOur reenonse ee a hole nunber

he production rate per day = units. (Enter your response as a whole number.) l in the table below. (Enter your responses as whole numbers.) Month 1 January Deman 900 2 February 3 March 4 April 5 May 6 June 700 800 1,200 1,500 1,100 he total regular production cost = S (Enter your response as a whole number.) he total subcontracting cost = $(Enter your response as a whole number.) otal cost with plan 5 = S (Enter your response as a whole number.) Juarez has yet a sixth plan. A constant workforce of 7 is selected, with the remainder of demand filled by subcontracting. Evaluate this plan. be production rate ner day =llunite (Enter vOur reenonse ee a hole nunber

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter9: Decision Making Under Uncertainty

Section: Chapter Questions

Problem 30P

Related questions

Question

please answer within 30 minutes. its urgent.

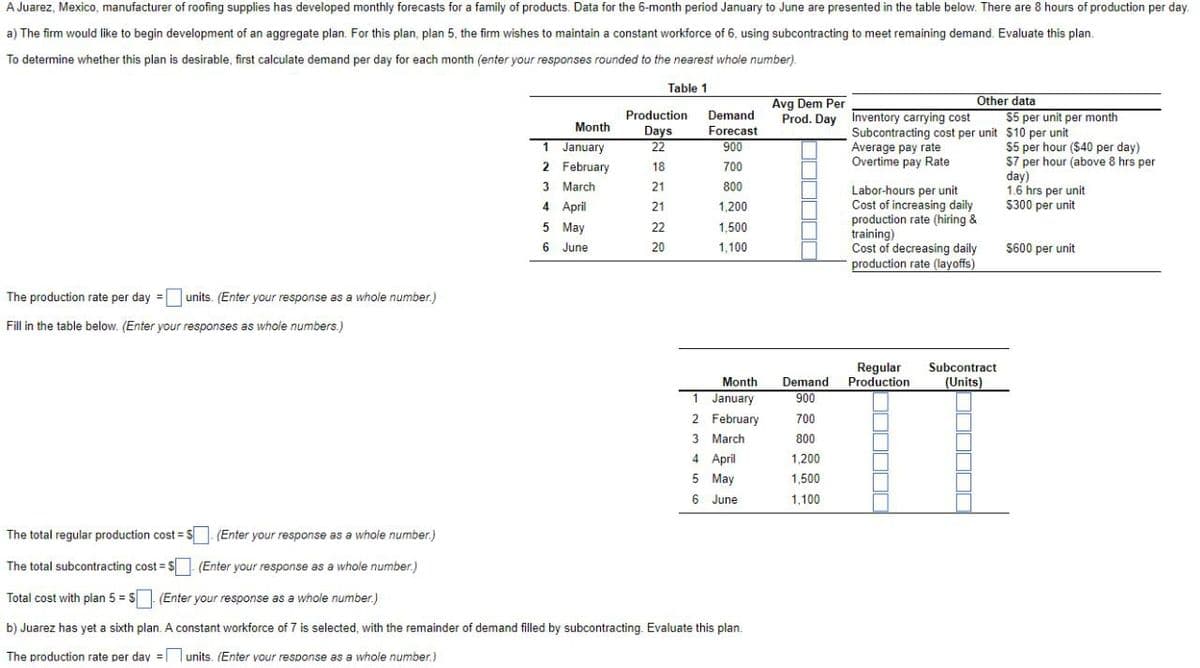

Transcribed Image Text:A Juarez, Mexico, manufacturer of roofing supplies has developed monthly forecasts for a family of products. Data for the 6-month period January to June are presented in the table below. There are 8 hours of production per day.

a) The firm would like to begin development of an aggregate plan. For this plan, plan 5, the firm wishes to maintain a constant workforce of 6, using subcontracting to meet remaining demand. Evaluate this plan.

To determine whether this plan is desirable, first calculate demand per day for each month (enter your responses rounded to the nearest whole number).

Table 1

Avg Dem Per

Prod. Day Inventory carrying cost

Other data

$5 per unit per month

Production

Demand

Month

Days

22

Forecast

Subcontracting cost per unit $10 per unit

Average pay rate

Overtime pay Rate

$5 per hour ($40 per day)

$7 per hour (above 8 hrs per

day)

1.6 hrs per unit

$300 per unit

1 January

2 February

900

18

700

3 March

21

800

Labor-hours per unit

Cost of increasing daily

production rate (hiring &

training)

Cost of decreasing daily

production rate (layoffs)

4 April

21

1,200

5 May

22

1,500

6 June

20

1,100

S600 per unit

The production rate per day = units. (Enter your response as a whole number.)

Fill in the table below. (Enter your responses as whole numbers.)

Regular

Production

Subcontract

Month

Demand

(Units)

1 January

2 February

900

700

3 March

800

4 April

1,200

5 May

1,500

6 June

1,100

The total regular production cost = S (Enter your response as a whole number.)

The total subcontracting cost = $ (Enter your response as a whole number.)

Total cost with plan 5 = S (Enter your response as a whole number.)

b) Juarez has yet a sixth plan. A constant workforce of 7 is selected, with the remainder of demand filled by subcontracting. Evaluate this plan.

The production rate per day =| Tunits. (Enter vour response as a whole number.)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 2 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Marketing

Marketing

ISBN:

9780357033791

Author:

Pride, William M

Publisher:

South Western Educational Publishing

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Marketing

Marketing

ISBN:

9780357033791

Author:

Pride, William M

Publisher:

South Western Educational Publishing