he question below is from the attached image of a video case file from Operations Management: Processes and Supply Chains (11th Edition) by Krajewski, L. J., Malhotra, M. K. & Ritzman, L. P. Attached a video case discussion from chapter 12. Question three is here below: 3. Regarding the design of the Washable Deluxe Painting Kit supply chain, Crayola must evaluate the strategy of next-shoring in Asia or retaining an existing network that involves the assembly of the kits in the U.S. Compare and contrast these two supply chain designs from perspective of the decision factors and pitfalls for outsourcing discussed in the text

he question below is from the attached image of a video case file from Operations Management: Processes and Supply Chains (11th Edition) by Krajewski, L. J., Malhotra, M. K. & Ritzman, L. P. Attached a video case discussion from chapter 12. Question three is here below: 3. Regarding the design of the Washable Deluxe Painting Kit supply chain, Crayola must evaluate the strategy of next-shoring in Asia or retaining an existing network that involves the assembly of the kits in the U.S. Compare and contrast these two supply chain designs from perspective of the decision factors and pitfalls for outsourcing discussed in the text

Chapter13: Services Marketing

Section: Chapter Questions

Problem 5DYMP

Related questions

Question

The question below is from the attached image of a video case file from Operations Management: Processes and Supply Chains (11th Edition) by Krajewski, L. J., Malhotra, M. K. & Ritzman, L. P.

Attached a video case discussion from chapter 12. Question three is here below:

3. Regarding the design of the Washable Deluxe Painting Kit supply chain, Crayola must evaluate the strategy of next-shoring in Asia or retaining an existing network that involves the assembly of the kits in the U.S. Compare and contrast these two supply chain designs from perspective of the decision factors and pitfalls for outsourcing discussed in the text

Transcribed Image Text:VIDEO CASE

Supply Chain Design at Crayola

Crayola LLC is a profitable wholly-owned subsidiary of Hallmark Cards of

Kansas City, Missouri. The company's world headquarters are located in

Easton, Pennsylvania and house marketing, sales, operations & manufactur-

ing, finance, R&D, Internet services, customer care consumer affairs and cor-

porate communications. Sales offices in Easton, Bentonville, Arkansas, and

Minneapolis manage domestic accounts, while offices in Canada, Mexico,

France, Italy, Japan, and Hong Kong handle international business. The

Global Operations Division in Easton is responsible for the sourcing, quality,

manufacturing, and logistics of Crayola products worldwide.

Two thirds of what Crayola sells globally is produced in its three Penn-

Washable

DeluxePainting Kit

Crsyola,

sylvania facilities in the Lehigh Valley. The "Forks I" plant is devoted to man-

ufacturing crayons and markers, the "Forks II" plant handles plastic molding,

and the Lehigh Valley Industrial Park (LVIP) plant creates paints, modeling

compounds, activity kits, and Silly Putty®. A single 800,000 square foot

distribution center in nearby Bethlehem, Pennsylvania handles finished

goods for logistics to U.S. and international customers, and to global busi-

ness units.

JEABILN m OES OF

4 VATERCOLOR PAINTS 4 BRISHES-55

AT SACCI

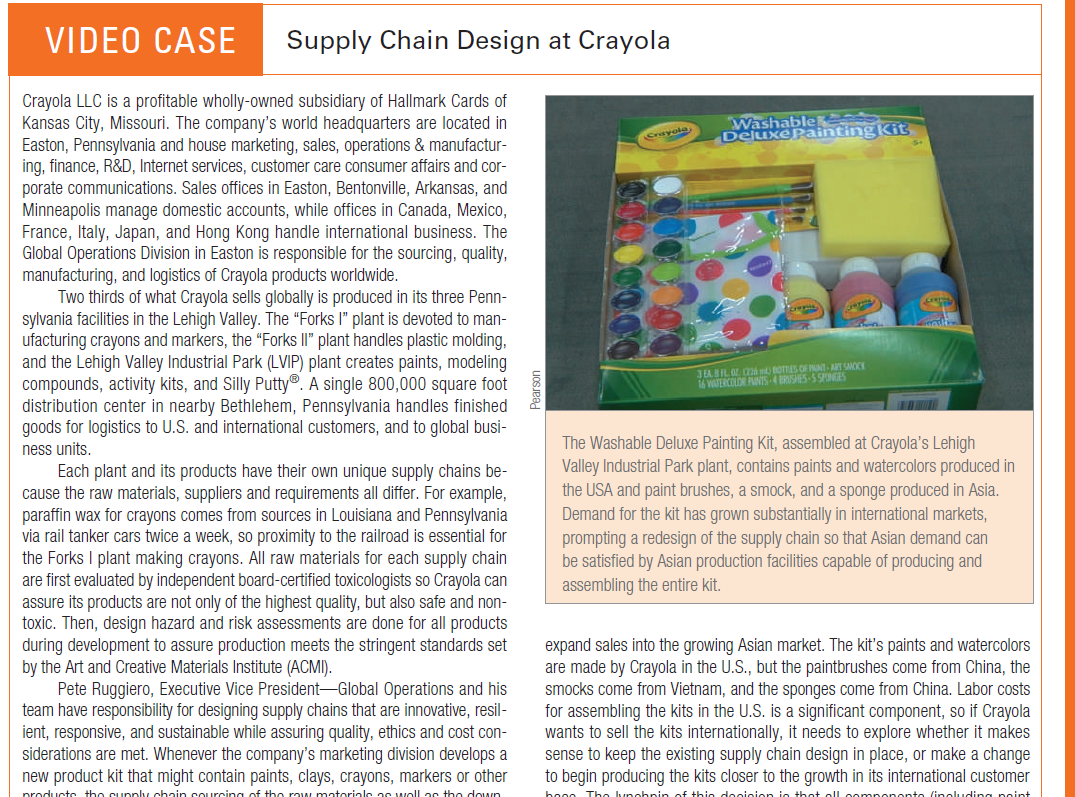

The Washable Deluxe Painting Kit, assembled at Crayola's Lehigh

Valley Industrial Park plant, contains paints and watercolors produced in

the USA and paint brushes, a smock, and a sponge produced in Asia.

Demand for the kit has grown substantially in international markets,

prompting a redesign of the supply chain so that Asian demand can

be satisfied by Asian production facilities capable of producing and

assembling the entire kit.

Each plant and its products have their own unique supply chains be-

cause the raw materials, suppliers and requirements all differ. For example,

paraffin wax for crayons comes from sources in Louisiana and Pennsylvania

via rail tanker cars twice a week, so proximity to the railroad is essential for

the Forks I plant making crayons. All raw materials for each supply chain

are first evaluated by independent board-certified toxicologists so Crayola can

assure its products are not only of the highest quality, but also safe and non-

toxic. Then, design hazard and risk assessments are done for all products

during development to assure production meets the stringent standards set

by the Art and Creative Materials Institute (ACMI).

Pete Ruggiero, Executive Vice President-Global Operations and his

team have responsibility for designing supply chains that are innovative, resil-

ient, responsive, and sustainable while assuring quality, ethics and cost con-

siderations are met. Whenever the company's marketing division develops a

new product kit that might contain paints, clays, crayons, markers or other

expand sales into the growing Asian market. The kit's paints and watercolors

are made by Crayola in the U.S., but the paintbrushes come from China, the

smocks come from Vietnam, and the sponges come from China. Labor costs

for assembling the kits in the U.S. is a significant component, so if Crayola

wants to sell the kits internationally, it needs to explore whether it makes

sense to keep the existing supply chain design in place, or make a change

to begin producing the kits closer to the growth in its international customer

producte tho cupplyLchain COurcin g of tho row matoriale ac woll ac tho down

booo The lynohpin of thie dooigion io that olL oompo nonto (inoluding point

Transcribed Image Text:expand sales into the growing Asian market. The kit's paints and watercolors

are made by Crayola in the U.S., but the paintbrushes come from China, the

smocks come from Vietnam, and the sponges come from China. Labor costs

for assembling the kits in the U.S. is a significant component, so if Crayola

wants to sell the kits internationally, it needs to explore whether it makes

sense to keep the existing supply chain design in place, or make a change

to begin producing the kits closer to the growth in its international customer

base. The lynchpin of this decision is that all components (including paint

and watercolor trays historically manufactured in the United States) need to

be made in Asia to make production efficient, and minimize duties and lead

times. By producing the entire product–including its components and pack-

aging-in Asia, Crayola is able to optimize its delivered cost to the markets.

Producing this product in the U.S. and shipping it to Asia would be an impedi-

ment because of cost and lead time challenges.

during development to assure production meets the stringent standards set

by the Art and Creative Materials Institute (ACMI).

Pete Ruggiero, Executive Vice President-Global Operations and his

team have responsibility for designing supply chains that are innovative, resil-

ient, responsive, and sustainable while assuring quality, ethics and cost con-

siderations are met. Whenever the company's marketing division develops a

new product kit that might contain paints, clays, crayons, markers or other

products, the supply chain sourcing of the raw materials as well as the down-

stream production processes must be addressed to be sure the forecasted

demand can be accommodated within the existing facilities. Not long ago, the

company introduced an innovative new product called ColorWonder® that con-

sists of pens that only write on the special paper they are packed with for sale.

This required examining whether the existing supply chain could support the

addition of producing the specialized ink markers, where to source the coated

paper, and how to best create the kits containing both markers and paper.

Now in production, ColorWonder® is a best seller worldwide, with nearly

40 percent of Japanese sales coming from this product alone. Managers

received feedback from the market that the pens in the kits were lasting

longer than the paper, so the supply chain responded by creating separate

paper packets so consumers may purchase just the paper after the initial

pages in the kit are used. The result of this action has had a ripple effect on

the demand for markers, which is now lower, since consumers are buying

fewer full kits but more Color Wonder® books, so the supply chain and pro-

duction had to adjust once again.

Another major challenge is the assembly of kits whose components

are derived from diverse supply chains and assembled into finished products

in the company's LVIP plant. An example is the popular Washable Deluxe

Painting Kit®. The kit consists of paints and watercolors, paint brushes,

smocks for the artist, and sponges for special effects. The company wants to

QUESTIONS

1. Describe the text's four external and internal pressures on supply chain

design as they relate to Crayola's supply chains for ColorWonder® and

Washable Deluxe Painting Kit®.

2. Review the strategic implications of supply chains as described in the

text. Does Crayola have efficient or responsive supply chains, or both?

Explain your position.

3. Regarding the design of the Washable Deluxe Painting Kit® supply

chain, Crayola must evaluate the strategy of next-shoring in Asia or

retaining an existing network that involves the assembly of the kits in

the U.S. Compare and contrast these two supply chain designs from

perspective of the decision factors and pitfalls for outsourcing dis-

cussed in the text.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps