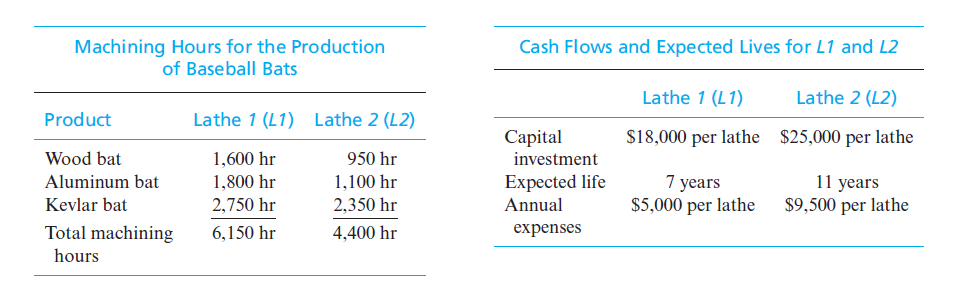

Machining Hours for the Production of Baseball Bats Cash Flows and Expected Lives for L1 and L2 Lathe 1 (L1) Lathe 2 (L2) Product Lathe 1 (L1) Lathe 2 (L2) Сapital investment $18,000 per lathe $25,000 per lathe Wood bat 1,600 hr 950 hr 7 years $5,000 per lathe $9,500 per lathe Aluminum bat 1,800 hr 1,100 hr Expected life 11 years Kevlar bat 2,750 hr 2,350 hr Annual Total machining 6,150 hr 4,400 hr expenses hours

Synchronous Generator

In comparison to an asynchronous generator, it is a machine where the rotor speed is equal to the rotating magnetic field produced by the stator, i.e., mechanical speed is equal to the electrical speed, thus called synchronous, and not asynchronous.

Salient Pole Rotor

Salient pole rotor includes a large number of exposed poles mounted on a magnetic wheel. The construction of a bright pole is as shown in the image on the left. The proposed poles are made of metal laminations. The rotor winding is provided on these poles and is supported by pole shoes.

Three models of baseball bats will be manufactured in a new plant in Pulaski. Each bat requires some manufacturing time at either Lathe 1 or Lathe 2, according to the following table. Your task is to help decide which type of lathe to install. Show and explain all work to support your recommendation. The plant will operate 3,000 hours per year. Machine

availability is 85% for Lathe 1 and 90% for Lathe 2. Scrap rates for the two lathes are 5% versus 10% for L1 and L2, respectively. Cash flows and expected lives for the two lathes are given in the following table. Annual operating expenses are based on an assumed operation of 3,000 hours per year, and workers are paid during any idle time of L1 and L2. Upper management has decided that MARR = 18% per year. Solve, a. How many type L1 lathes will be required to meet the machine-hour requirement?

b. What is the CR cost of the required type L2 lathes? c. What is the annual operating expense of the type L2 lathes? d. Which type of lathe should be selected on the basis of lowest total equivalent annual cost?

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 2 images