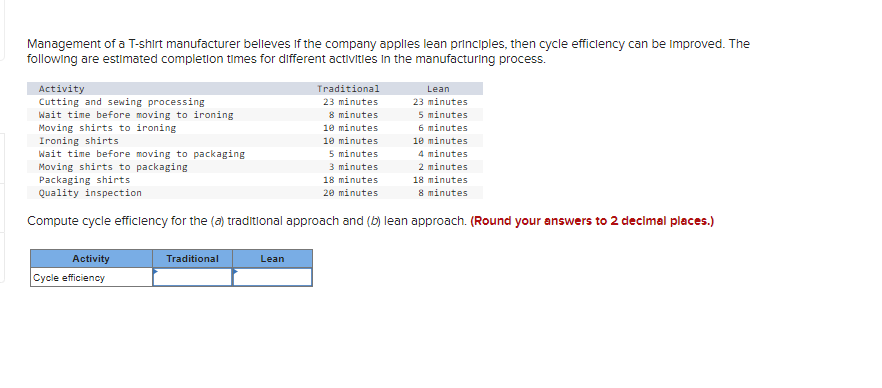

Management of a T-shirt manufacturer belleves if the company applies lean principles, then cycle efficiency can be improved. The following are estimated completion times for different activities in the manufacturing process. Activity Cutting and sewing processing Wait time before moving to ironing Moving shirts to ironing Ironing shirts Wait time before moving to packaging Moving shirts to packaging Activity Cycle efficiency Traditional Traditional 23 minutes 8 minutes Lean 10 minutes 10 minutes Packaging shirts Quality inspection 18 minutes 20 minutes Compute cycle efficiency for the (a) traditional approach and (b) lean approach. (Round your answers to 2 decimal places.) 5 minutes 3 minutes Lean 23 minutes 5 minutes 6 minutes 10 minutes 4 minutes 2 minutes 18 minutes 8 minutes

Management of a T-shirt manufacturer belleves if the company applies lean principles, then cycle efficiency can be improved. The following are estimated completion times for different activities in the manufacturing process. Activity Cutting and sewing processing Wait time before moving to ironing Moving shirts to ironing Ironing shirts Wait time before moving to packaging Moving shirts to packaging Activity Cycle efficiency Traditional Traditional 23 minutes 8 minutes Lean 10 minutes 10 minutes Packaging shirts Quality inspection 18 minutes 20 minutes Compute cycle efficiency for the (a) traditional approach and (b) lean approach. (Round your answers to 2 decimal places.) 5 minutes 3 minutes Lean 23 minutes 5 minutes 6 minutes 10 minutes 4 minutes 2 minutes 18 minutes 8 minutes

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Transcribed Image Text:Management of a T-shirt manufacturer believes if the company applies lean principles, then cycle efficiency can be improved. The

following are estimated completion times for different activities in the manufacturing process.

Activity

Cutting and sewing processing

Wait time before moving to ironing

Moving shirts to ironing

Ironing shirts

Wait time before moving to packaging

Moving shirts to packaging

Activity

Cycle efficiency

Traditional

Traditional

23 minutes

8 minutes

10 minutes

10 minutes

5 minutes

3 minutes

Packaging shirts

Quality inspection

18 minutes

20 minutes

Compute cycle efficiency for the (a) traditional approach and (b) lean approach. (Round your answers to 2 decimal places.)

Lean

Lean

23 minutes

5 minutes

6 minutes

10 minutes

4 minutes

2 minutes

18 minutes

8 minutes

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.