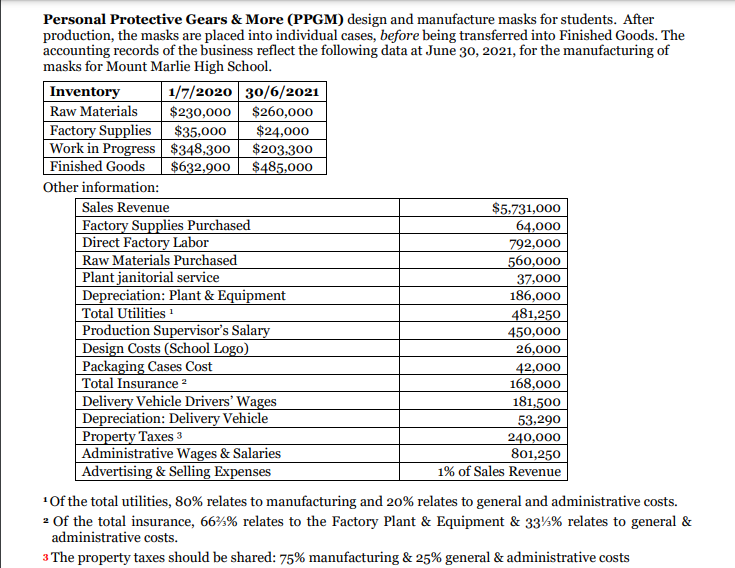

Required: a) Calculate the raw material used by Personal Protective Gears & More. b) Calculate the factory supplies used by Personal Protective Gears & More. c) What is the total factory overhead costs incurred by Personal Protective Gears & More during the period? d) Determine the prime cost & conversion cost of the masks manufactured. e) Prepare a schedule of cost of goods manufactured for the year ended June 30, 2021, clearly showing total manufacturing cost & total manufacturing costs to account for. f) Prepare an income statement for personal Protective Gears & More for the year ended June 30, 2021. List the non-manufacturing overheads in order of size starting with the largest. g) What is the selling price per mask if Personal Protective Gears manufactured 1,850 masks for the period under review and uses a mark-up of 25% on cost? h) How does the format of the income statement for a manufacturing concern differ from the income statement of a merchandising entity?

Required:

a) Calculate the raw material used by Personal Protective Gears & More.

b) Calculate the factory supplies used by Personal Protective Gears & More.

c) What is the total

period?

d) Determine the prime cost & conversion cost of the masks manufactured.

e) Prepare a schedule of cost of goods manufactured for the year ended June 30, 2021, clearly showing

total manufacturing cost & total manufacturing costs to account for.

f) Prepare an income statement for personal Protective Gears & More for the year ended June 30, 2021.

List the non-manufacturing overheads in order of size starting with the largest.

g) What is the selling price per mask if Personal Protective Gears manufactured 1,850 masks for the

period under review and uses a mark-up of 25% on cost?

h) How does the format of the income statement for a manufacturing concern differ from the income

statement of a merchandising entity?

Step by step

Solved in 3 steps with 3 images

Prepare a schedule of cost of goods manufactured for the year ended June 30, 2021, clearly showing

total manufacturing cost & total

Determine the prime cost & conversion cost of the masks manufactured.

g) What is the selling price per mask if Personal Protective Gears manufactured 1,850 masks for the

period under review and uses a mark-up of 25% on cost?